Turbine mould shell wax-injection device

A mold shell and wax injection technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of unguaranteed product quality and inability to ensure that the rotation angle is in place, and achieve the effect of product quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

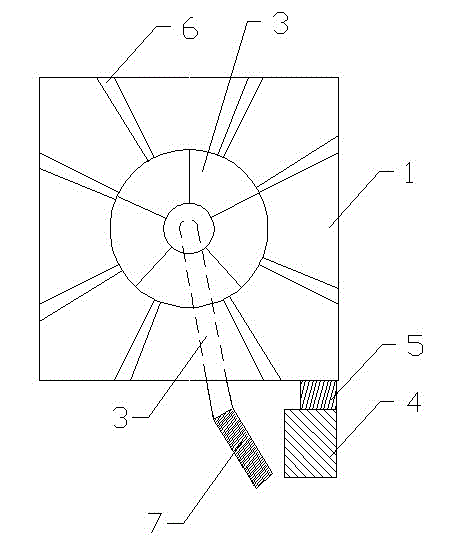

[0017] see figure 1 , a turbine formwork wax injection device that the present invention relates to, it includes a lower mold base 1, a lower mold 2 is arranged on the lower mold base 1, a rotating rod 3 is arranged below the lower mold 2, through which the rotating rod 3 To control the gathering and dispersion of the lower mold 2, the outer end of the rotating rod 3 is provided with a metal wrench 7, one side of the lower mold base 1 is provided with a magnet 4, and one side of the magnet 4 is provided with a sensor 5, The upper surface of the lower mold base 1 is provided with divergent cooling grooves 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com