A pipe shed installation device for underground engineering tunnels

An installation device and technology for underground engineering, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as low installation efficiency, inability to connect conduits, thread deformation, etc., to improve moving efficiency and reduce the number of manual thread supplements , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

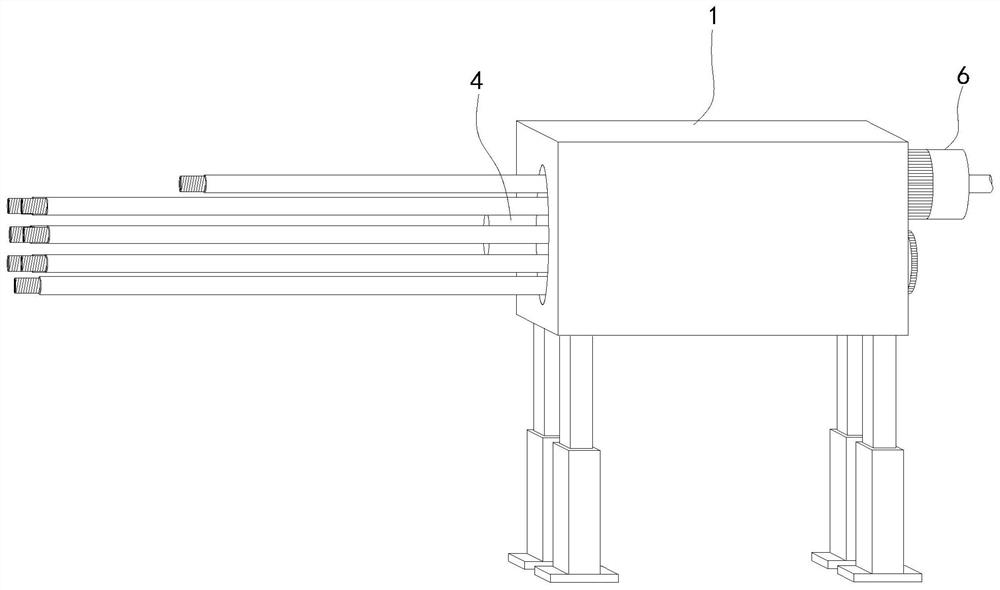

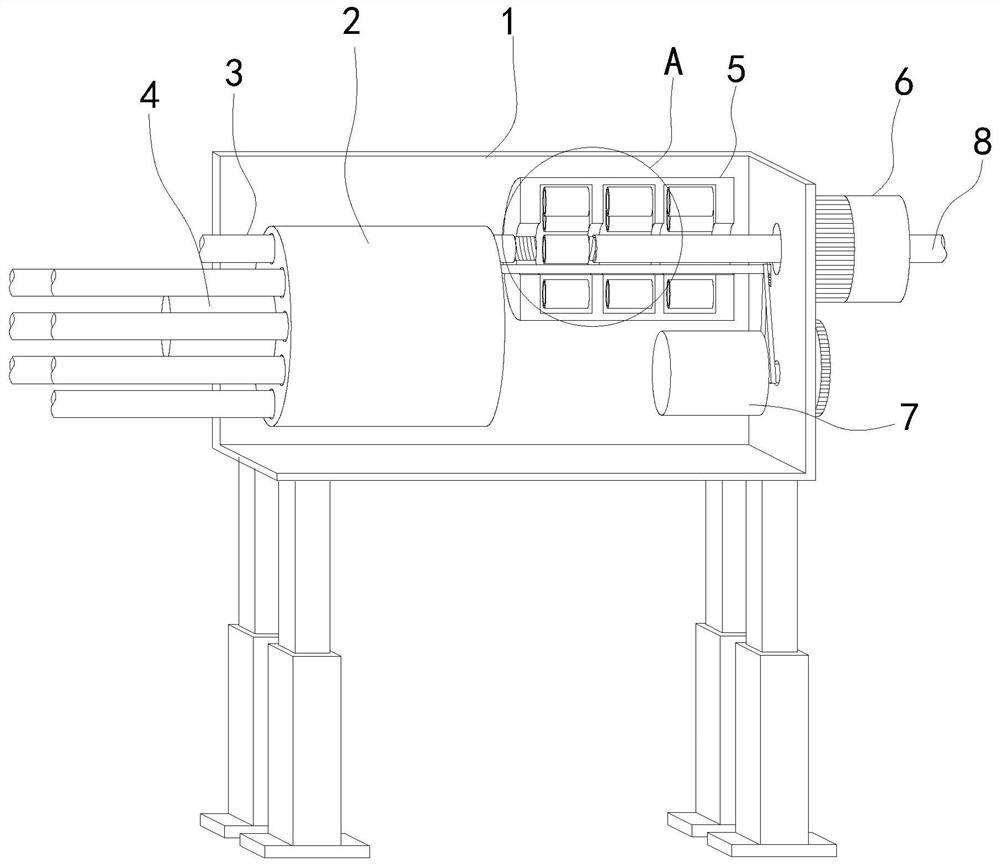

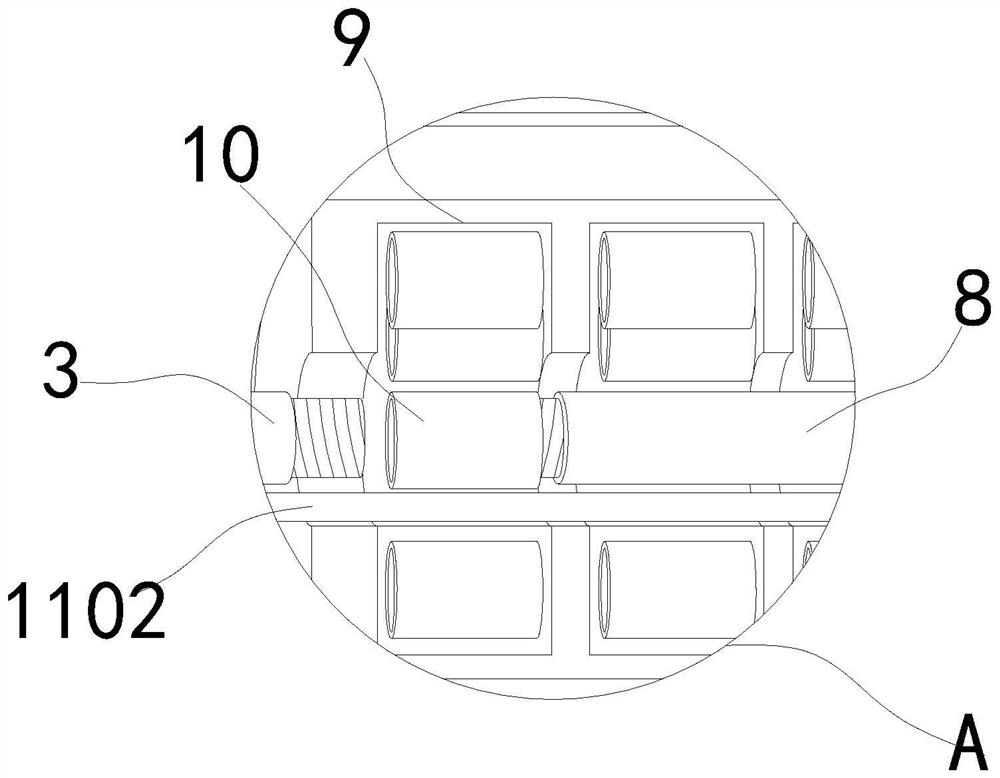

[0028] see Figures 1 to 10 , a planar structure schematic diagram and a three-dimensional structural schematic diagram of a tube shed installation device for an underground engineering tunnel.

[0029] A pipe shed installation device for underground engineering tunnels, including a device main body, characterized in that: a pipe transfer device is fixedly installed inside the device main body, a screw thread installation device is fixedly installed on the right end of the device main body, and a propulsion device.

[0030] In a specific implementation, a rotating layer is movably installed inside the tube transfer device, a catheter lumen is opened on the rotating layer and the bottom end of the catheter lumen is open, and a second catheter is movably installed in the catheter lumen, so that when the first motor 4 Drive the rotating propulsion rod 11 to rotate so that it can drive the second catheter 3 to move to the right through the bottom end of the catheter lumen 12 to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com