ABC superfine dry powder anti-reburning fire extinguishing agent and preparation method thereof

An ultra-fine dry powder, anti-re-ignition technology, used in fire prevention equipment and other directions, can solve the problems of not easily suspended in the fire zone, slow fire extinguishing reaction, large dosage, etc. quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

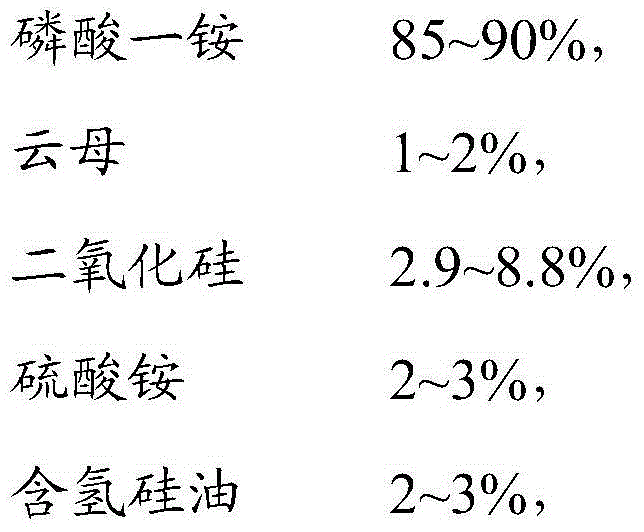

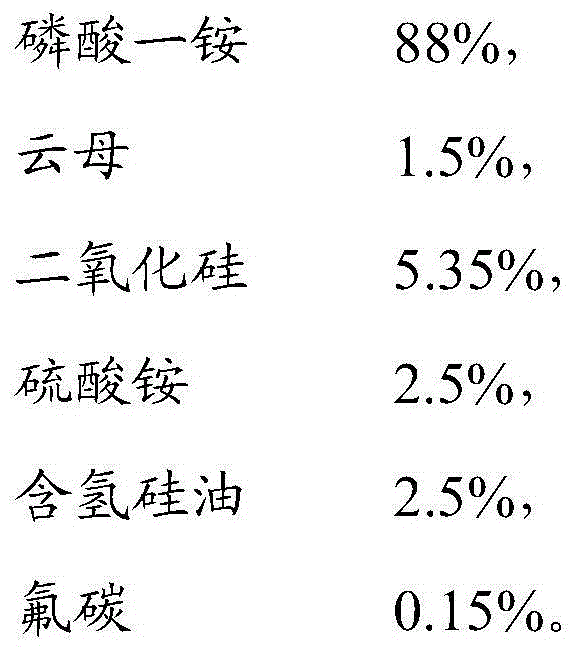

[0027] A kind of ABC superfine dry powder anti-resurgence fire extinguishing agent comprises the following steps:

[0028] 1) Mixing 88% food grade monoammonium phosphate by weight, 1.5% mica by weight, 5.35% silicon dioxide by weight and 2.5% ammonium sulfate by weight, and then adding weight by spraying The hydrogen-containing silicone oil with a percentage of 1% and the solvent oil equivalent to the hydrogen-containing silicone oil are stirred at high speed by a high-speed mixer for 30 minutes to obtain product A;

[0029] 2) The product A is pulverized with a high-speed jet mill until more than 90% of the particles have a particle size of less than 15 microns to obtain the product B;

[0030] 3) Add the product B into the reaction vessel, heat up and stir, and when the temperature of the product B rises to 60°C, add 1.5% by weight hydrogen-containing silicone oil and 3 times the amount of hydrogen-containing silicone oil by spraying Water is heated at a constant temperatu...

Embodiment 2

[0032] A kind of ABC superfine dry powder anti-resurgence fire extinguishing agent comprises the following steps:

[0033] 1) Mixing 85% food grade monoammonium phosphate by weight, 2% mica by weight, 8.8% silicon dioxide by weight and 2% ammonium sulfate by weight, and then adding weight by spraying Hydrogen-containing silicone oil with a percentage of 0.5% and toluene equivalent to the hydrogen-containing silicone oil were stirred at high speed by a high-speed mixer for 25 minutes to obtain product A;

[0034] 2) The product A is pulverized with a high-speed jet mill until more than 90% of the particles have a particle size of less than 15 microns to obtain the product B;

[0035] 3) Add the product B into the reaction vessel, heat up and stir, when the temperature of the product B rises to 55°C, add 1.5% by weight hydrogen-containing silicone oil and 3 times the amount of hydrogen-containing silicone oil by spraying Water is heated at a constant temperature of 85°C for 3 h...

Embodiment 3

[0037] A kind of ABC superfine dry powder anti-resurgence fire extinguishing agent comprises the following steps:

[0038] 1) 90% by weight of food grade monoammonium phosphate, 1% by weight of mica, 2.9% by weight of silicon dioxide and 3% by weight of ammonium sulfate are mixed, and then added by spraying Hydrogen-containing silicone oil with a percentage of 1% and toluene equivalent to the hydrogen-containing silicone oil were stirred at high speed by a high-speed mixer for 40 minutes to obtain product A;

[0039] 2) The product A is pulverized with a high-speed jet mill until more than 90% of the particles have a particle size of less than 15 microns to obtain the product B;

[0040] 3) Add the product B into the reaction vessel, heat up and stir, and when the temperature of the product B rises to 65°C, add 2% by weight hydrogen-containing silicone oil and 3 times the amount of hydrogen-containing silicone oil by spraying Water is heated at a constant temperature of 100°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com