Matching testing method and system used for wheel speed sensor and target wheel

A wheel speed sensor and target wheel technology, which is applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, instruments, etc. Can not reflect the wheel speed sensor matching and other issues well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

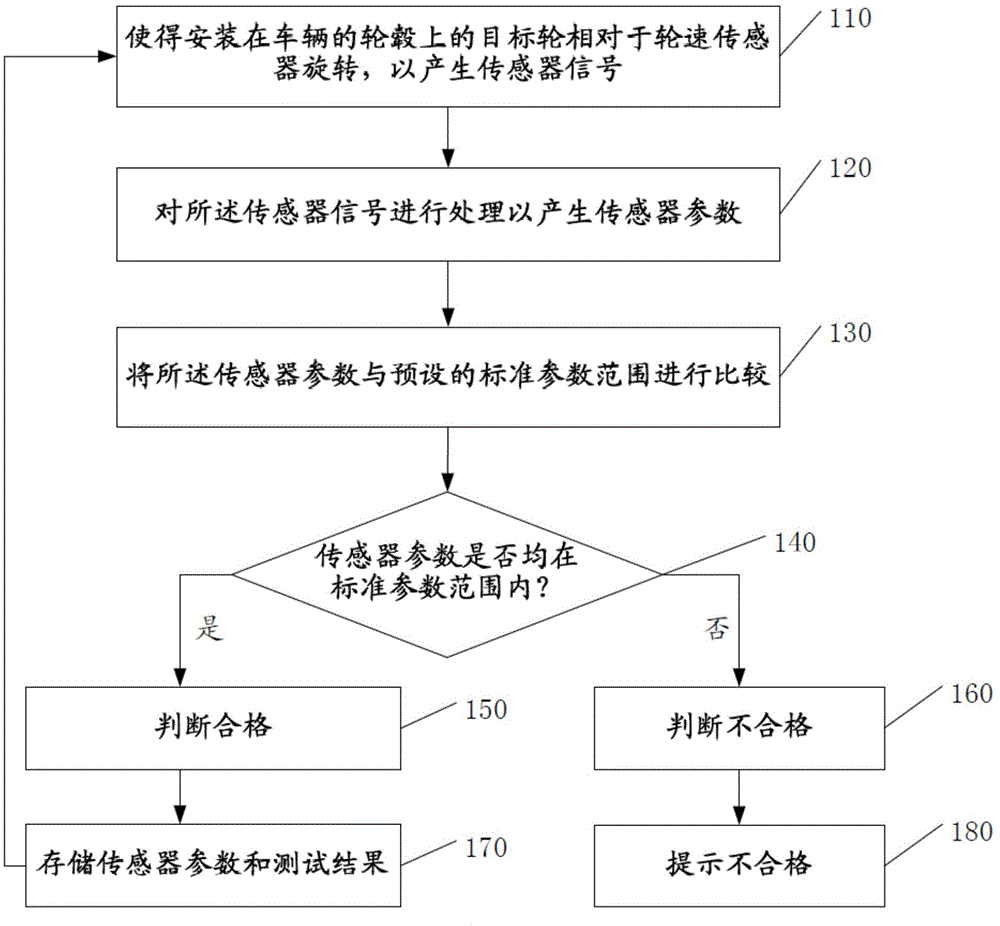

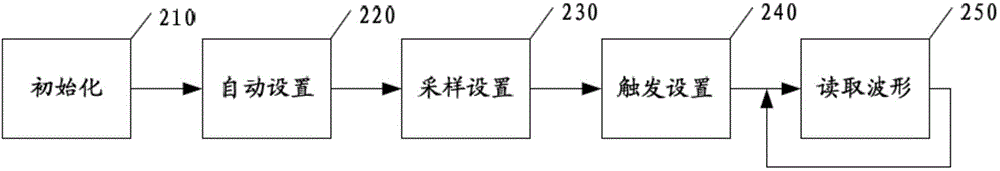

Method used

Image

Examples

Embodiment approach

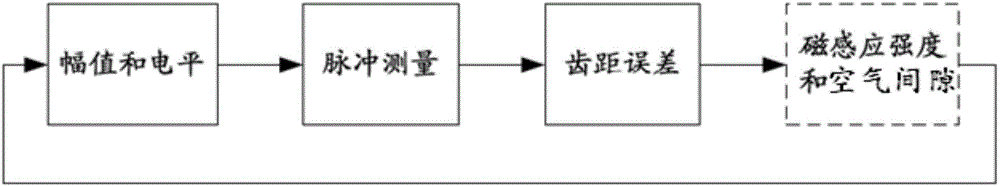

[0039] According to one embodiment, the high voltage is the level when the pulse (corresponding to the square wave) or the transient waveform reaches the highest state, the low voltage is the level when the pulse or transient waveform reaches the lowest state, and the period is twice adjacent The time interval of crossing the middle reference level in the same direction, the pulse width is the difference between the first two intersection times of the pulse specified by the pulse number and the middle reference level,

[0040] The duty cycle is calculated according to the difference of the pulse polarity by the following formula: or

[0041] The tooth pitch error is calculated by the pulse cycle specified by the pulse number according to the following formula: Where n=1, 2, . . . , N, N is a positive integer greater than 2, Tn is the length of the nth period, and Tavg is the average value of the period.

[0042] According to an implementation manner, when the wheel speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com