Method for detecting self safety of polyurethane grouting reinforcement material for underground coal mine in use process

A technology of grouting reinforcement and detection method, which is applied in the field of detecting whether the polyurethane grouting reinforcement material will smolder when it is used in underground coal mines, so as to achieve the effect of ensuring its own safety and the method is simple and fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The formula of the polyurethane grouting reinforcement material to be tested that this embodiment selects is:

[0062] Component A:

[0063] Component B: Polyisocyanate PAPI 110 parts

[0064] This embodiment takes the polyurethane grouting reinforcement material as an example to illustrate the detection method of the present invention, and the specific steps are as follows:

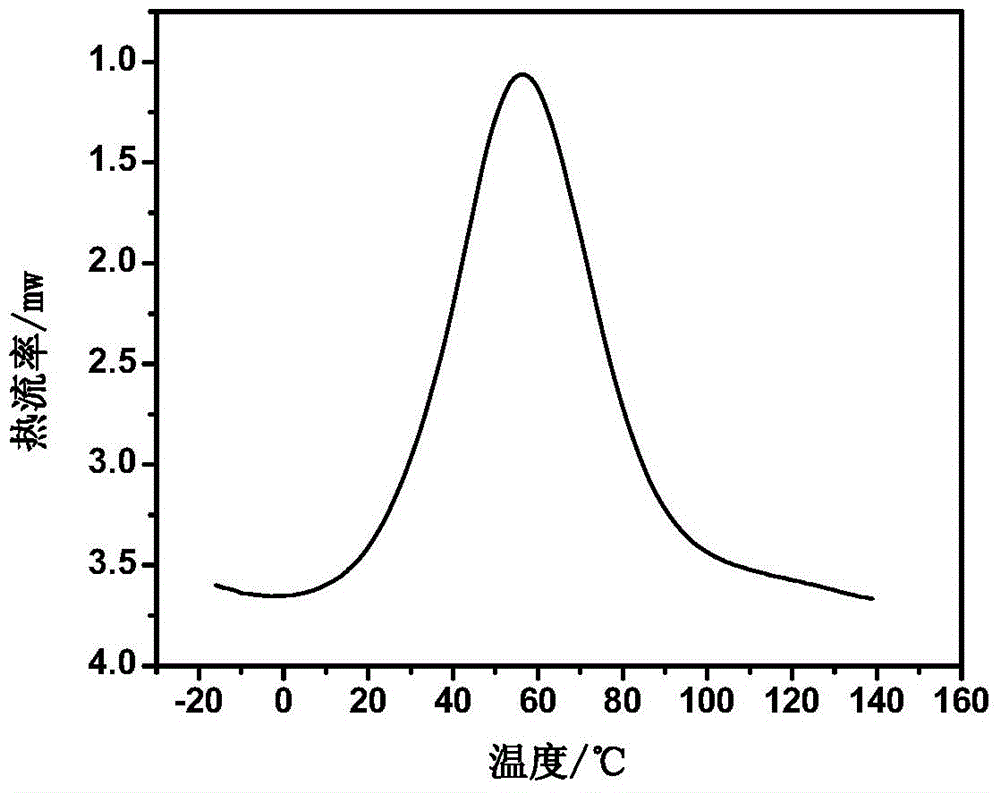

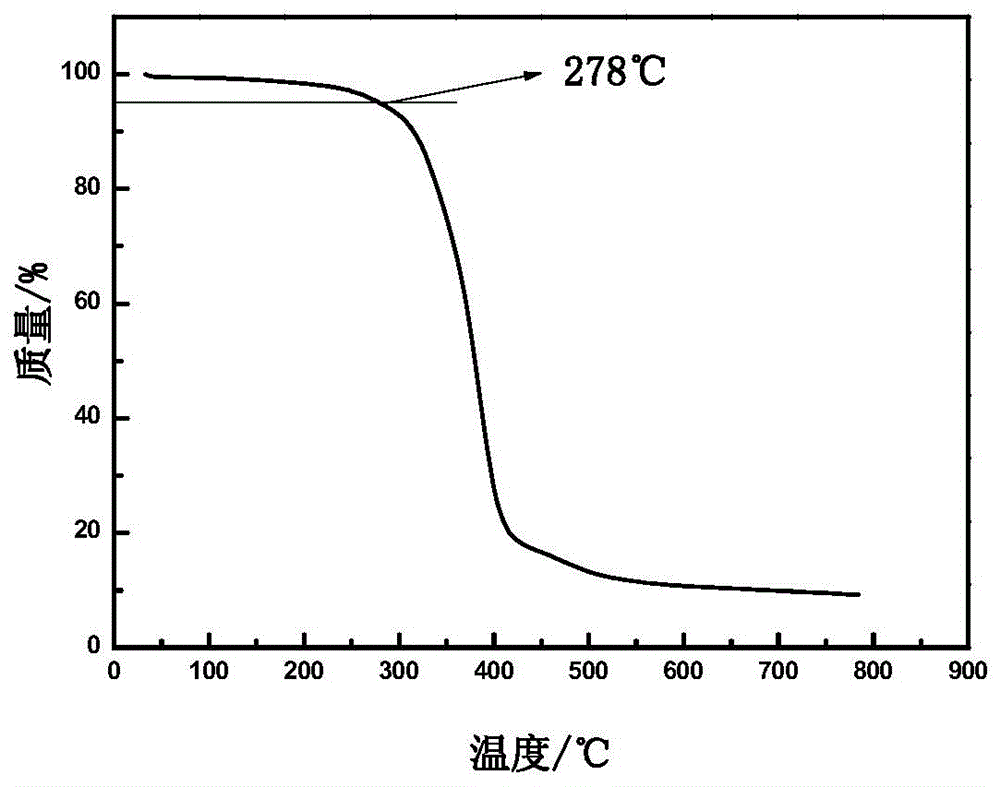

[0065] 1. Determination of the theoretical maximum reaction temperature T of the polyurethane grouting reinforcement material during the curing process max :

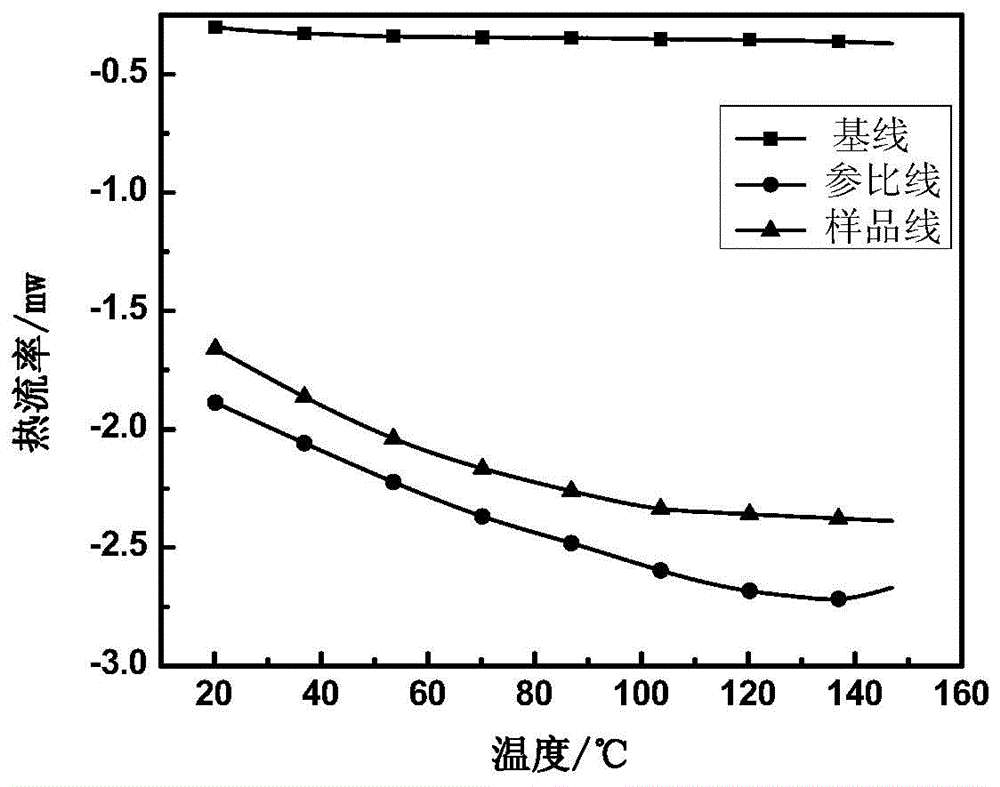

[0066] a. Differential scanning calorimeter (DSC) indirect method to test the specific heat capacity C of polyurethane grouting reinforcement material p :

[0067] a1. Select two empty crucibles, one of which is pressed and sealed as a reference plate, and the other set is covered but not sealed as a sample plate and put into the DSC;

[0068] a2. Set up and run the following program: raise the temperature from 20°C to 150°C at a hea...

Embodiment 2

[0085] The formula of the polyurethane grouting reinforcement material to be tested that this embodiment selects is:

[0086] Component A:

[0087] Component B: polyisocyanate PAPI 71 parts

[0088] This embodiment takes the polyurethane grouting reinforcement material as an example to illustrate the detection method of the present invention, and the specific steps are as follows:

[0089] 1. Determination of the theoretical maximum reaction temperature T of the polyurethane grouting reinforcement material during the curing process max :

[0090] a. Differential scanning calorimeter (DSC) indirect method to test the specific heat capacity C of polyurethane grouting reinforcement material p :

[0091] a1. Select two empty crucibles, one of which is pressed and sealed as a reference plate, and the other set is covered but not sealed as a sample plate and put into the DSC;

[0092] a2. Set up and run the following program: raise the temperature from 20°C to 150°C at a heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com