A flexible pipeline of thrust vector adjustment mechanism of electric propulsion system

A technology of thrust vectoring and adjusting mechanism, which is applied to the propulsion system devices, hoses, pipes and other directions of space navigation vehicles, can solve the problems of unpublished detailed information, unsatisfactory shape and structure, etc., and achieves small lateral displacement and stable relative position. , The effect of high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

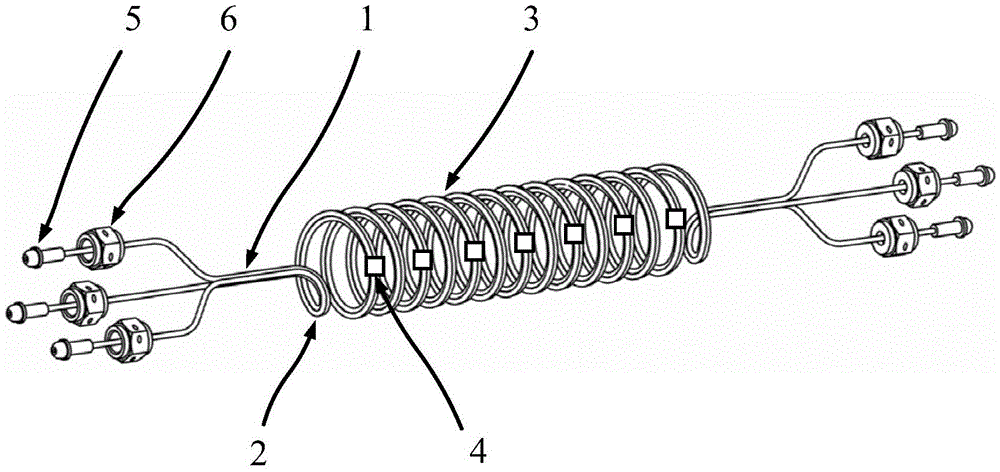

[0033] The outer diameter of the large-diameter helical section 3 is 41mm, the pitch is 12mm, the number of turns is 11, the length of the straight section is 300mm, the outer diameter of the capillary is 1.7mm, the inner diameter is 0.7mm, and the length of the heat shrinkable sleeve 4 is 5mm. 4 heat-shrinkable sleeves 4 are arranged on each spiral, the spherical diameter of the ball head 5 is 5.5mm, the minimum bending radius of the entire flexible pipeline is 8.5mm, the straight section 1, the small-diameter transition helical section 2 and the large-diameter helical section The material of 3 is cold-drawn and solution-treated stainless steel 1Cr18Ni9Ti, and the material of the ball head 5 and the jacket nut 6 is cold-drawn stainless steel 1Cr18Ni9Ti.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com