Automobile vortex type electric air conditioning compressor assembly

An electric air conditioner, scroll technology, applied in the field of compressors, can solve the problems of large volume, troublesome installation, heavy weight, etc., and achieve the effects of convenient maintenance, simplified structure, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in further detail below in conjunction with specific examples.

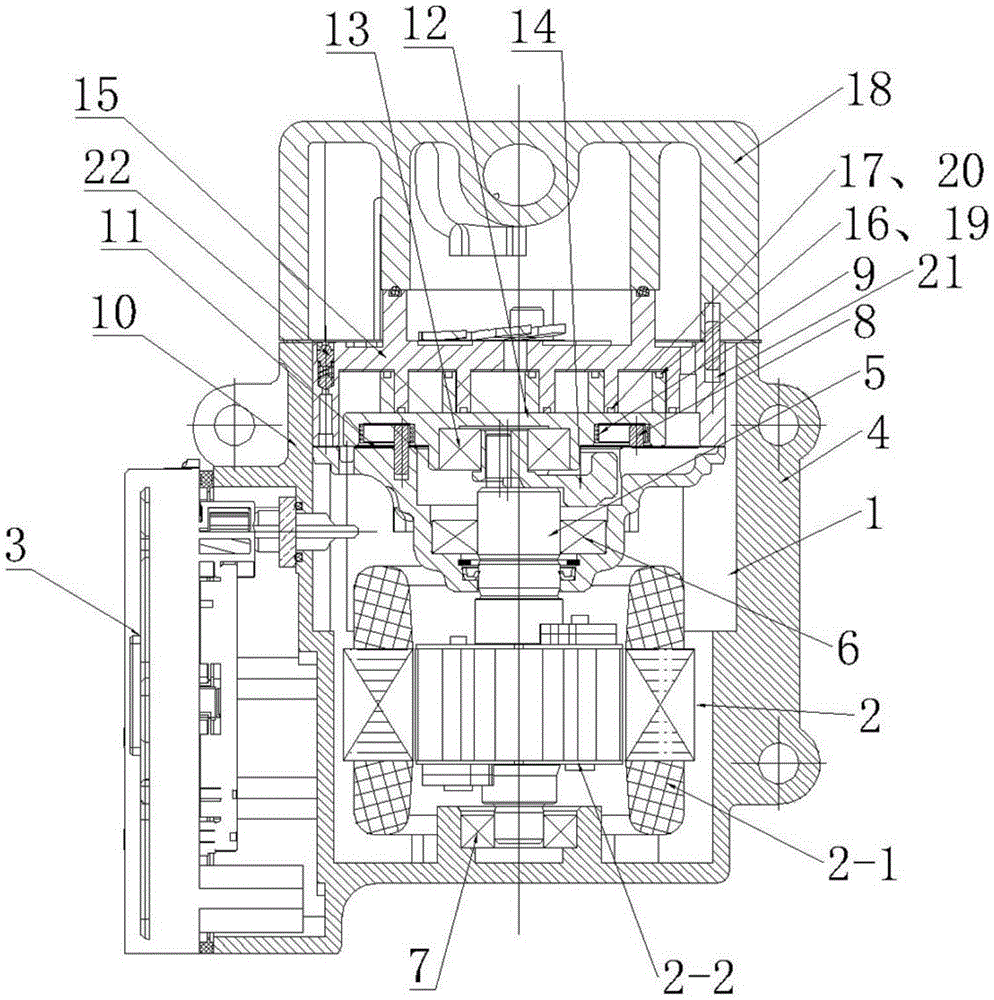

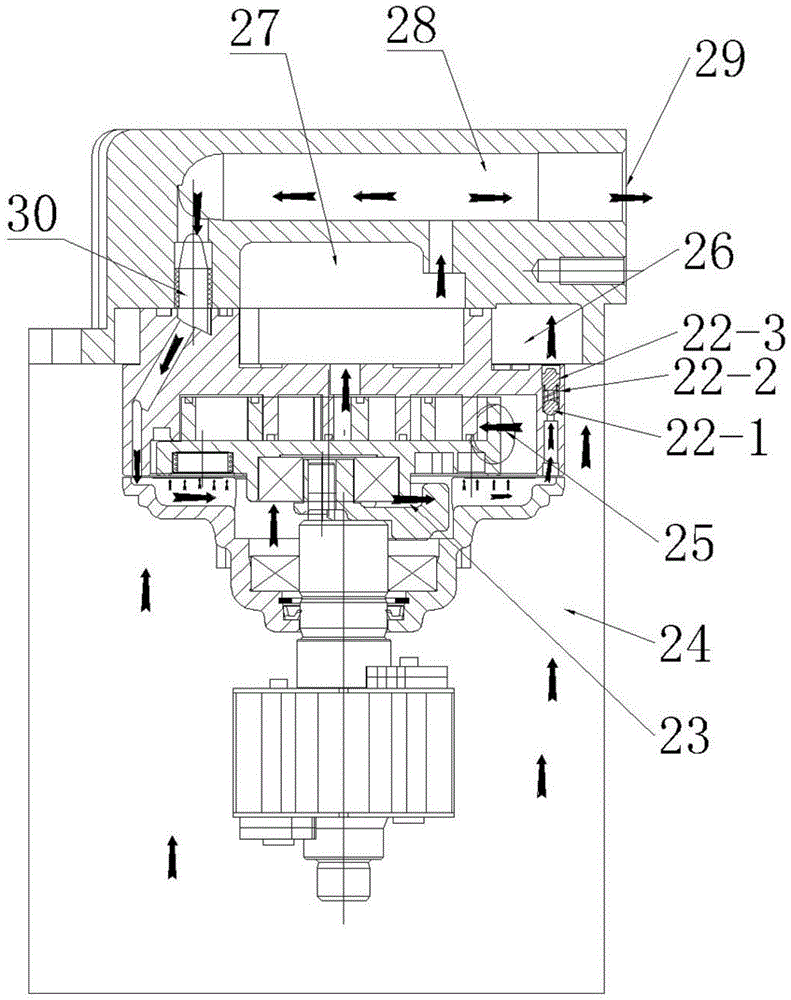

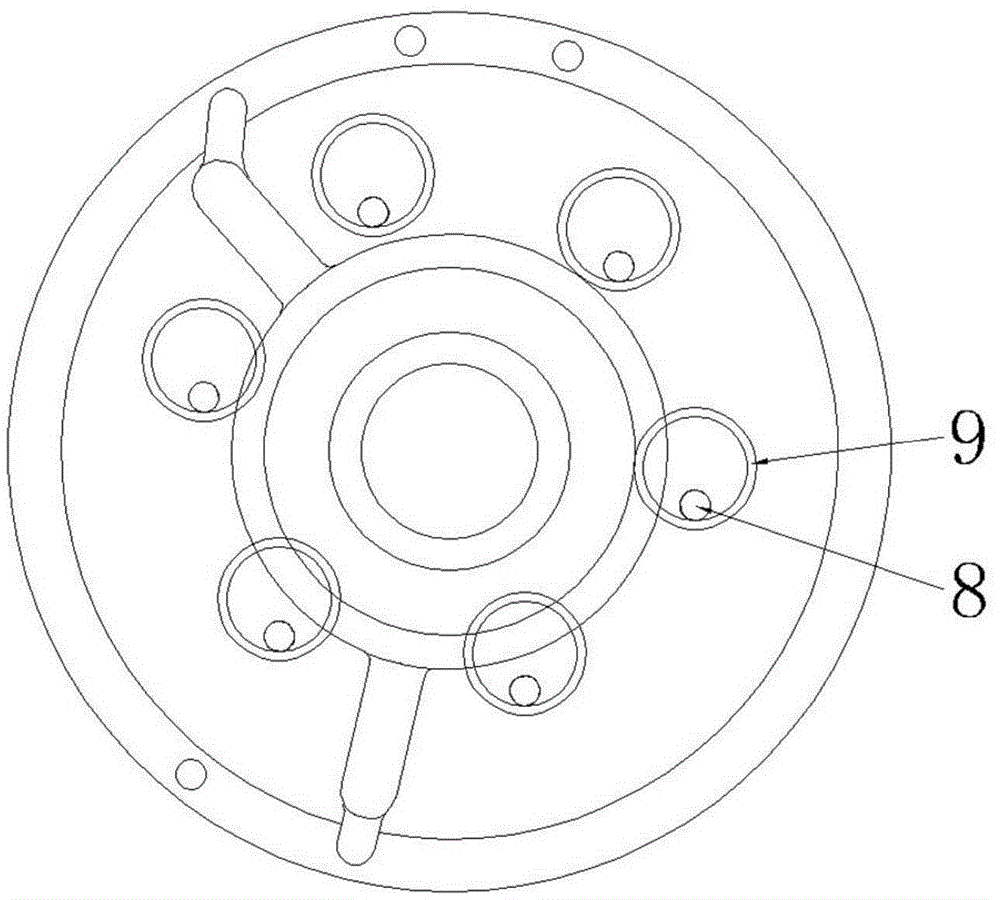

[0019] Such as figure 1 and figure 2 As shown, the present invention is an automobile scroll electric air-conditioning compressor assembly, which is an integrated semi-closed structure composed of a scroll compression device 1, a motor 2, and a controller 3. The scroll compression device 1 includes a shell Body 4, main eccentric shaft 5, main shaft upper bearing 6, main shaft lower bearing 7, anti-rotation pin group 8, anti-rotation ring group 9, bracket 10, wear-resistant pad 11, moving plate 12, moving plate bearing 13, eccentric sleeve 14 , the fixed plate 15, the moving plate sealing strip 16, the fixed plate sealing strip 17 and the end cover 18 fixed on the end of the housing, the stator 2-1 of the motor 2 is fixed in the housing, and the rotor 2-2 of the motor is installed in the main body On the eccentric shaft 5, the main eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com