Frequency conversion and energy saving monitoring system for water source well of oil field

A monitoring system and water source well technology, applied in pump control, liquid variable capacity machinery, machine/engine, etc., can solve the problems of electric energy waste, electric submersible pump idling can not automatically cut off the power, etc., to increase the load capacity, reliable Energy-saving monitoring equipment, remarkable energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

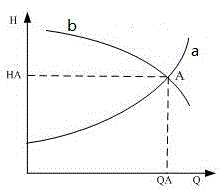

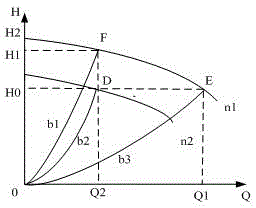

[0024] In order to make the water supply system of the water source well run stably, the water supply system must satisfy both the head characteristic and the pipe resistance characteristic. The head characteristic is based on the premise that the opening of the valve in the system pipeline is constant, which shows the relationship curve between the head H and the flow Q of the electric submersible pump at a certain speed. What the head characteristic reflects is the relationship H=f(Q) between the head H and the water flow Q.

[0025] The pipe resistance characteristic is based on the premise that the speed of the electric submersible pump is constant, indicating the relationship between the head H and the flow Q of the valve at a certain opening. The pipe resistance characteristics reflect the change law of the energy of the electric submersible pump used to overcome the water level and pressure difference of the electric submersible pump system, and the flow resistance of w...

Embodiment 2

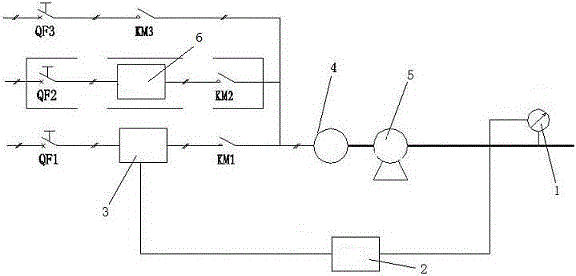

[0039] The frequency converter 3 that the present invention adopts is ABB frequency converter, ACS510 series, rated capacity is 55~90KW, as Figure 4 As shown, the PLC-based frequency conversion energy saving device ACS510 frequency converter control diagram: Terminals 5 and 6 are connected to M and I terminals of PLC to receive the analog signal of PLC controlling the output frequency of the frequency converter, and terminals 7 and 9 are connected to E+ and E of PLC - terminal, to send the frequency signal of the frequency converter, terminal 13 is connected to terminal 10 via the frequency conversion start KM2 button, terminals 10 and 13 are the start signals of the frequency converter; terminals 14 and 15 are connected to high-speed / low-speed switch SA2, 10 and 14 Terminal No. 1 is the high-speed selection function of the inverter, terminals 10 and 15 are the low-speed selection function of the inverter, and the high-speed and low-speed selection functions of the inverter ar...

Embodiment 3

[0046] The main control equipment for realizing constant voltage control in the frequency conversion energy-saving device is PLC. This system adopts Siemens S7-200 series PLC, which has a standard RS485 communication port and 1 Ethernet (Ethernet), RJ45 network port. It is small in size and easy to execute. Fast speed, strong anti-interference ability and superior performance. PLC is mainly used to realize the automatic control of frequency conversion energy-saving devices. It must complete the following functions: automatically control the operation of the electric submersible pump; have a soft start function when starting; have manual / automatic control functions for the operation of the electric submersible pump, manual Temporary use in emergency or maintenance; the system has a complete alarm function and can display the operating status. The rationality of the circuit and the reliability of the program are directly related to the operation performance of the whole system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com