Eccentric adjustable plunger pump

A plunger pump, adjustable technology, applied in the field of eccentric adjustable plunger pumps, can solve the problems of inconvenient adjustment of liquid delivery volume, fatigue damage of plastic pipes, etc., and achieve low cost, simple and reasonable structure, durable, convenient and simple adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with accompanying drawing, the present invention is described in further detail.

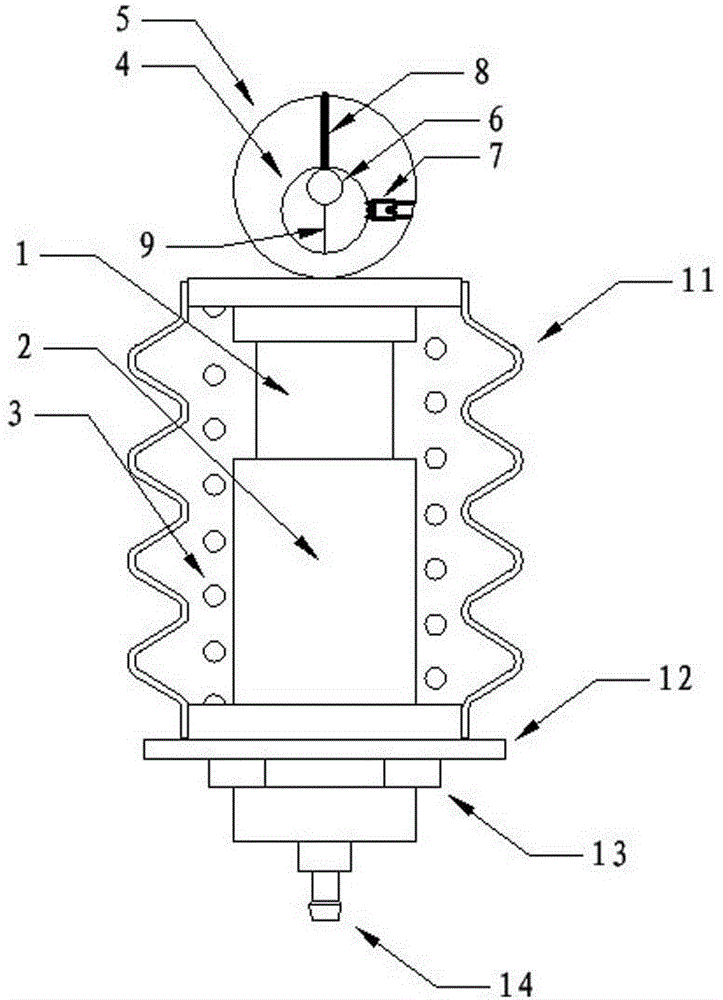

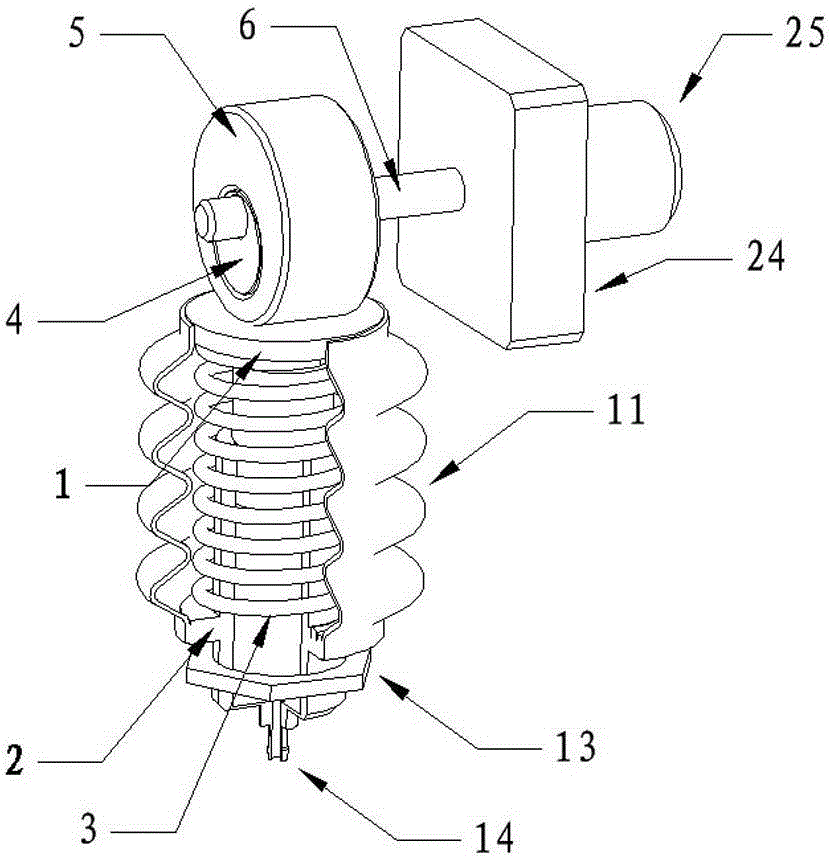

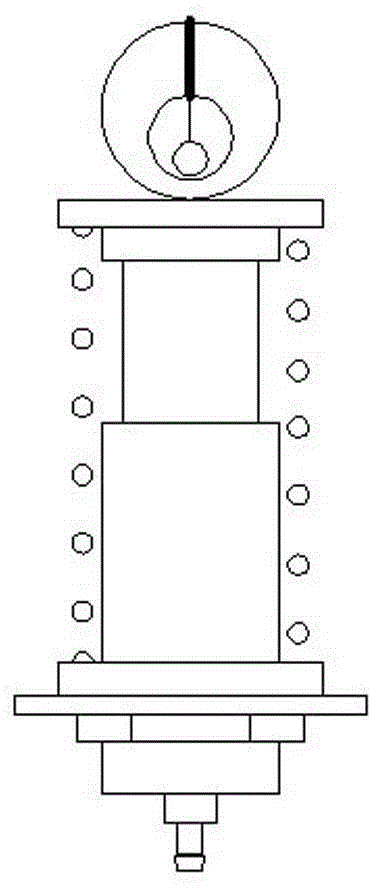

[0031] Such as figure 1 , figure 2 and Figure 7 The eccentric adjustable plunger pump shown includes an adjustable eccentric roller and a plunger pump. The adjustable eccentric roller includes a large cylinder 5 and a small cylinder 4. There is a loose fit between the large and small cylinders 4 and 5, and the small cylinder 4 can be inserted into the In the large cylinder 5, the small cylinder 4 is connected to the motor shaft 3 and the axes of the two are parallel but not coincident. The large cylinder 5 is provided with an adjustable countersunk head locking screw 7. The front end of the screw 7 is a conical surface, and the screw 7 can be tightened. The tapered surface of the front end of the screw squeezes the surface of the small cylinder 4 to achieve full locking of the large and small cylinders 4 and 5; the plunger pump includes a plunger 1, a cylinder body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com