Methane storage cabinet and methane tank containing same

A technology of gas storage cabinets and biogas digesters, applied in the field of biogas digesters, can solve the problems of pressurized power consumption, unfavorable transportation and installation of steel cabinets, complex installation structure, etc., and achieve the effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

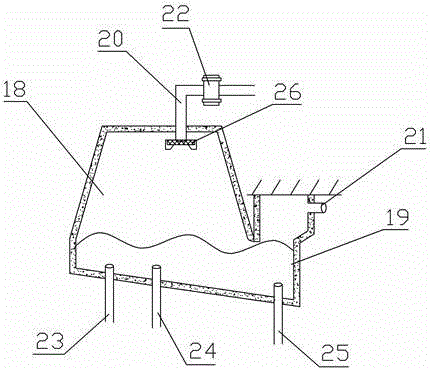

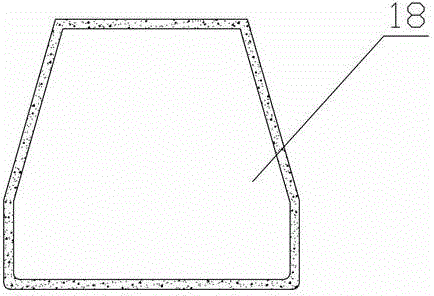

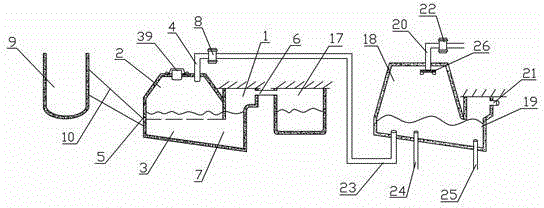

[0030] like figure 1 , figure 2 Shown, a kind of biogas storage tank, comprises gas storage tank 18 and sludge tank 19, the top of gas storage tank 18 is provided with gas delivery pipe 20, and the side wall of sludge tank 19 is provided with water outlet 21, and sludge The other side wall of the pool 19 communicates with the gas storage tank 18, and the bottom of the gas storage tank 18 slopes downward toward the connection between the sludge tank 19 and the gas storage tank 18, and extends to the place where the outlet 21 of the sludge tank 19 is located. Side wall; the cross-section of the bottom of the gas storage tank 18 is a concave hemispherical shape; the gas storage tank 18 is in the shape of a trapezoid with a narrow top and a wide bottom. The inclination angle of the bottom surface of the gas storage cabinet 18 is 30 degrees, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com