A processing technology for processing cylinder blank of hydraulic cylinder

A processing technology and technology of hydraulic cylinders, which are applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of large deviation of the inner diameter roundness of the hydraulic cylinder cylinder blank, large difference in the outer wall thickness of the hydraulic cylinder cylinder, The problem of high scrap rate can improve production efficiency, ensure product quality and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

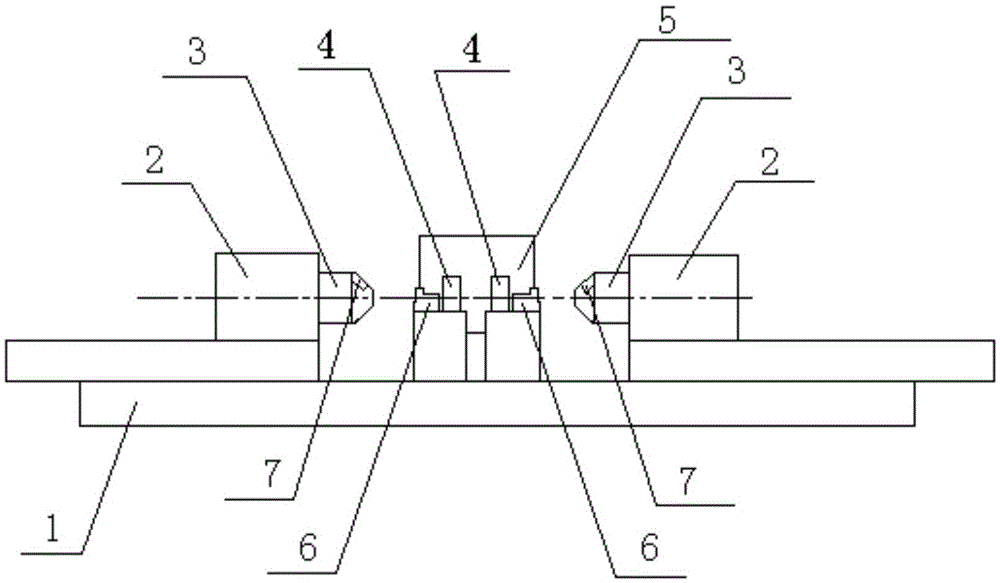

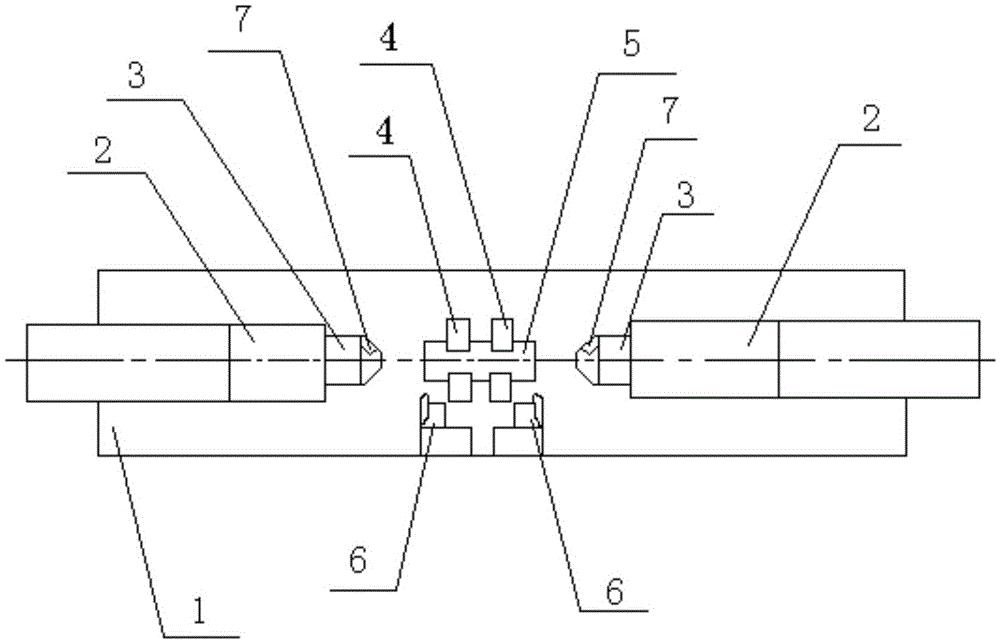

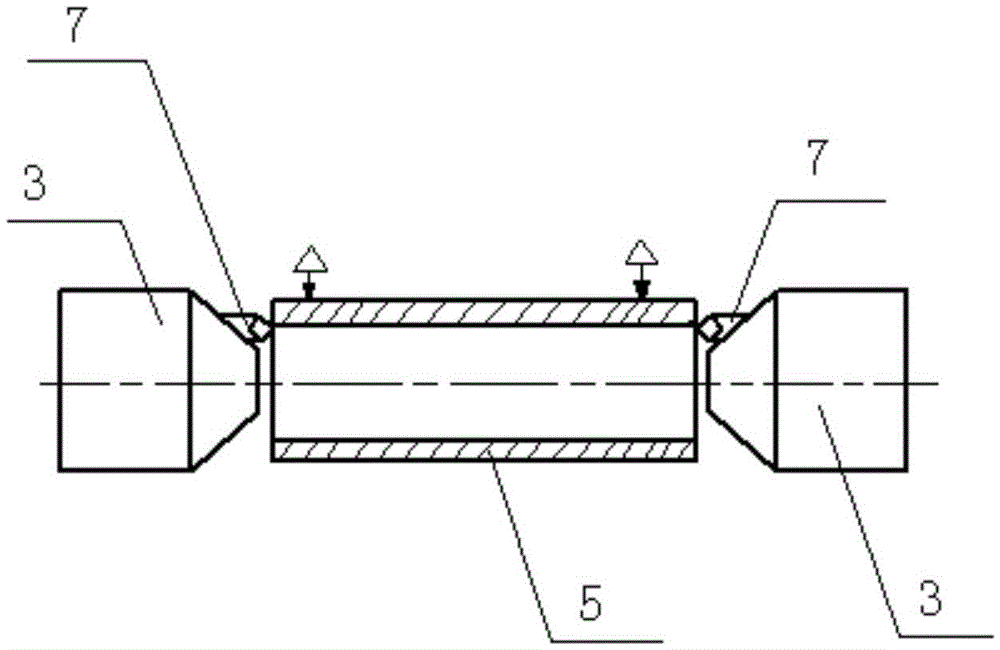

[0027] Such as figure 1 , figure 2 As shown, a device for processing hydraulic cylinder blanks according to the present invention includes a machine 1 , two power heads 2 , two numerically controlled cutter heads 6 , and two V-shaped blocks 4 . Two V-shaped blocks 4 are fixedly arranged in front and rear parallel to the center of the upper surface of the machine platform 1 , and the V-shaped blocks are used to clamp and fix the cylinder blank 5 of the hydraulic cylinder. The two CNC cutter heads 6 are movably connected to the machine platform 1 and are located on the same side of the two V-shaped blocks 4. The CNC cutter disks 6 can be moved and adjusted on the machine platform 1, and the two CNC cutter heads 6 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com