Vertical well cable construction device used for high-rise building

A technology for high-rise buildings and construction devices, applied in cable laying equipment and other directions, can solve the problems of the clamps of cables and steel wires being knocked off, the running route is not limited, and the cables are prone to shaking, etc., so as to reduce mutual friction, improve construction efficiency, reduce The effect of the probability of being damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

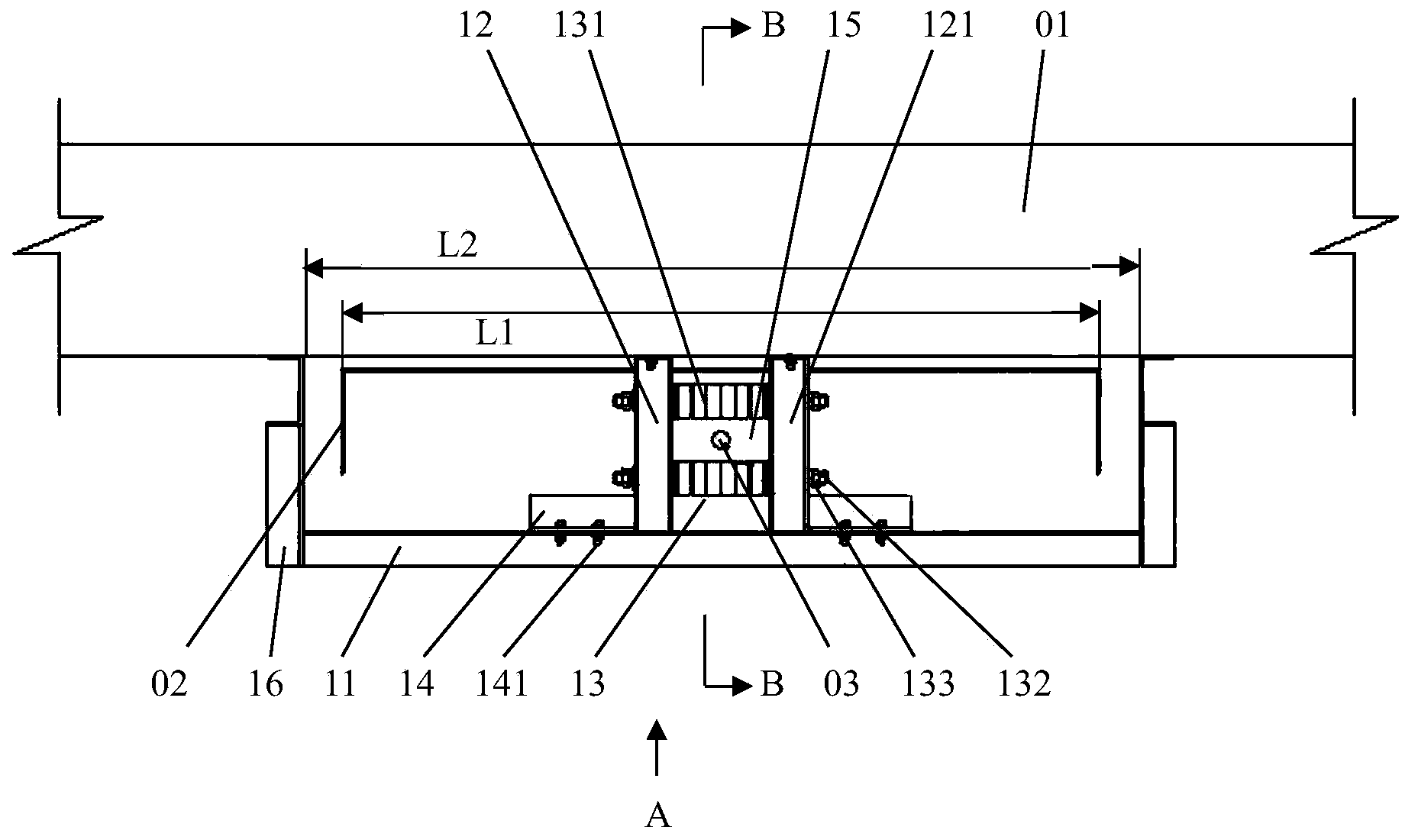

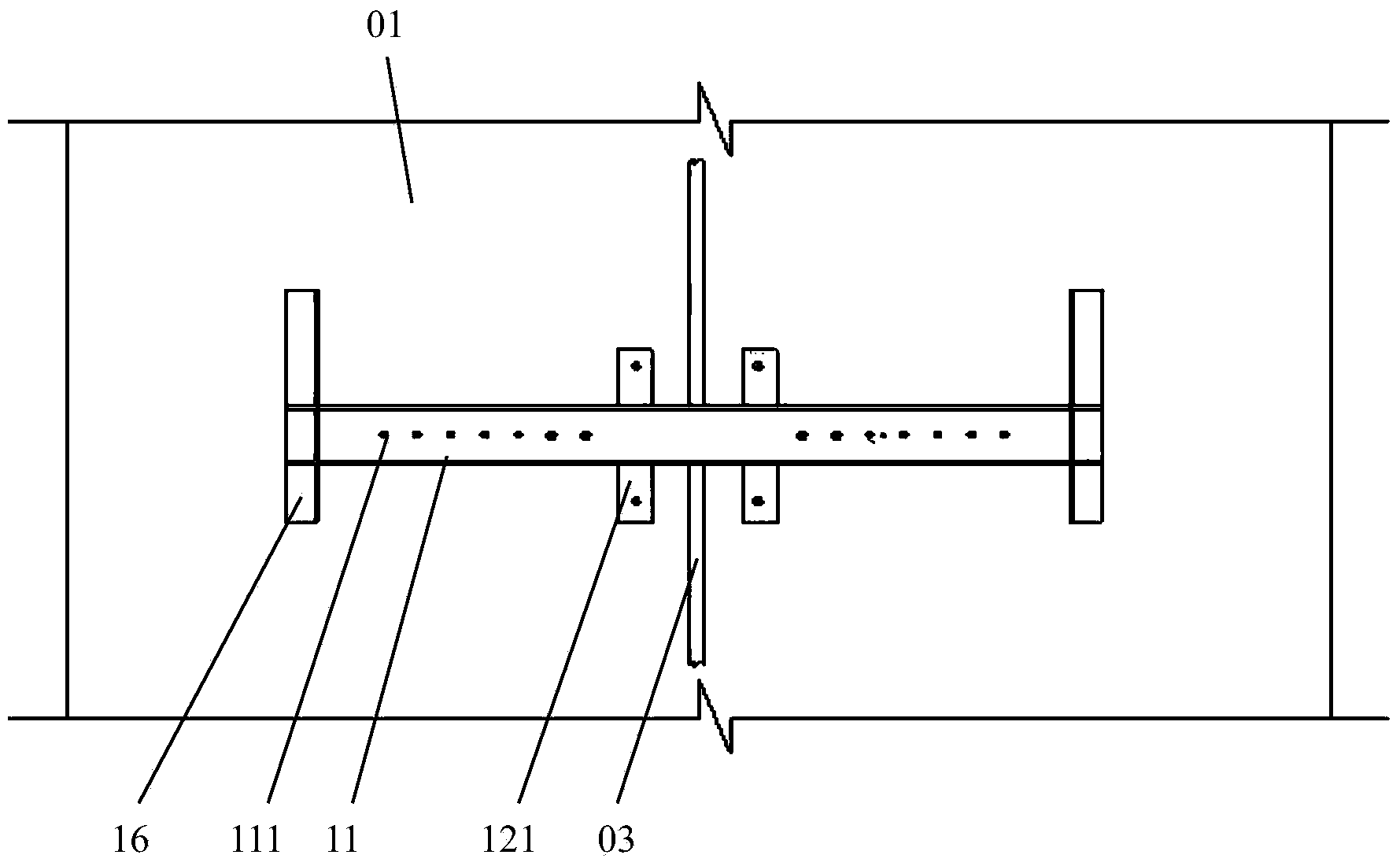

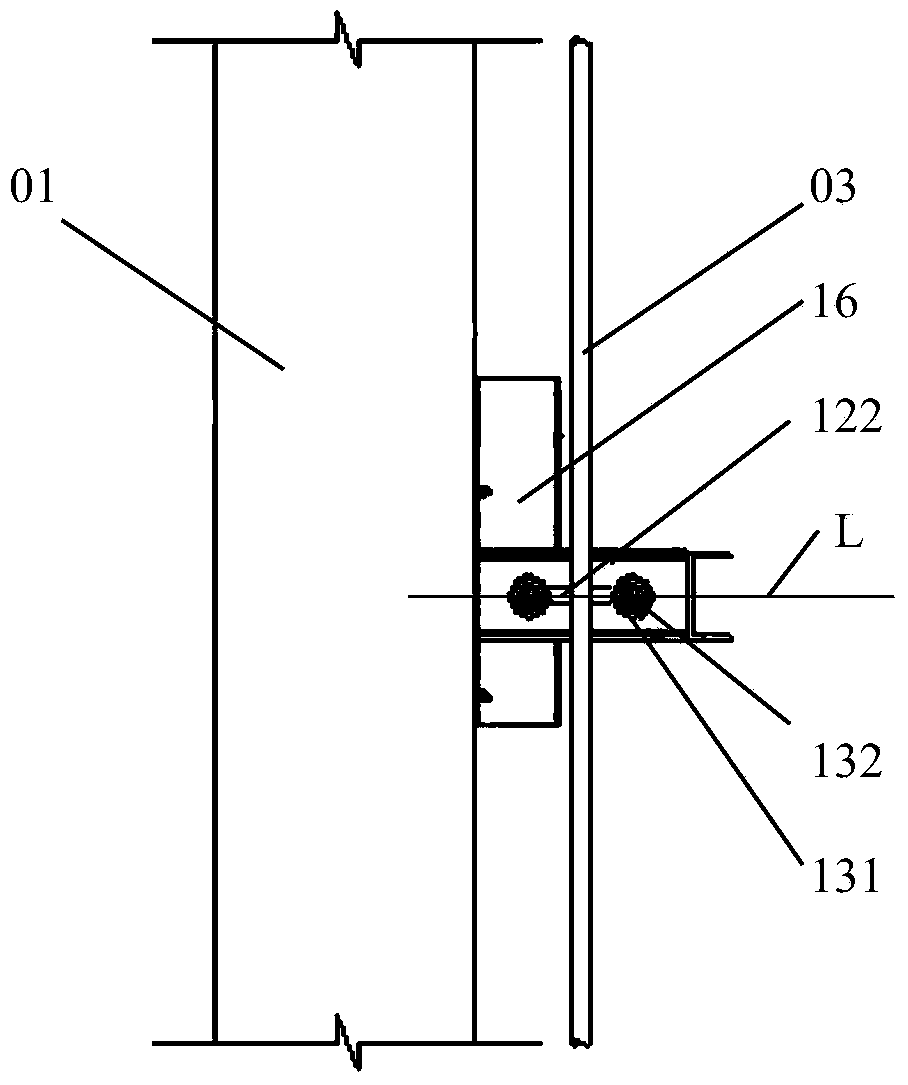

[0035] A shaft cable construction device for high-rise buildings, the structural diagram when it is installed on the wall of high-rise buildings 01 is detailed in figure 1 , figure 2 as well as image 3 , specifically including one or at least two groups of individual protection frames, adjacent two groups of individual protection frames can be arranged independently of each other along the height direction of the high-rise building 01, or can be connected in series sequentially, or can be connected in other ways.

[0036] The single protective frame includes a shelf crosspiece 11, a first set of limiting components 12 and a second set of limiting components 13, and the overall structure is simplified.

[0037] The frame-bending crosspiece 11 is coaxially arranged with the ladder frame 02 on the high-rise building 01, and its length L2 is 1.2-2.0 times of the length L1 of the ladder frame 02; At least two mounting holes 111; the first group of limiting components 12 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com