Homologous manganese oxide and spinel-type lithium manganate lithium ion battery and preparation method thereof

A technology of spinel lithium manganese oxide and lithium ion battery, which is applied in the field of homologous manganese oxide and spinel lithium manganate lithium ion battery and its preparation, and can solve the problems of low electronic conductivity, hindering materials, volume expansion, etc. problem, achieve the effect of reducing material usage and cost, simple steps and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the present invention will be further described by the following examples, which will help to understand the present invention, but do not limit the content of the present invention:

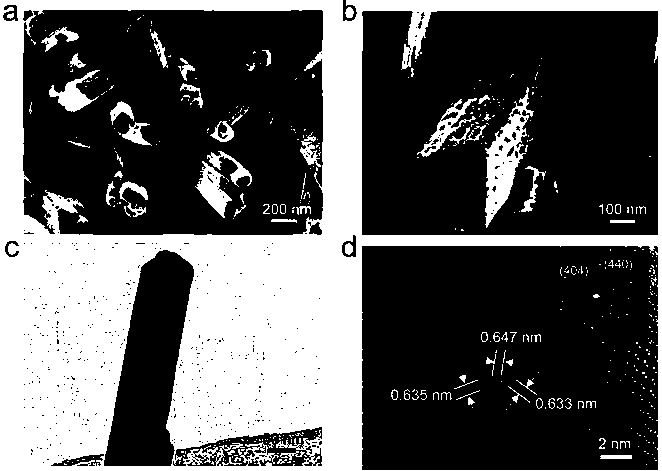

[0025] (1) After mixing water and dilute hydrochloric acid, add potassium permanganate to it, dissolve and form a solution under stirring, transfer it to a reaction kettle, put a titanium foil of appropriate size into the kettle, and react 24 pieces at 180°C Hour, obtain manganese dioxide nanowire array;

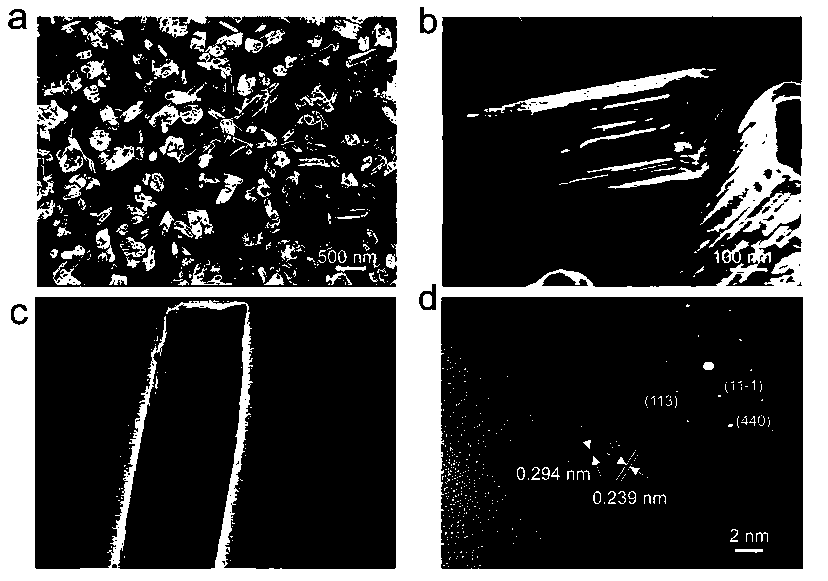

[0026] (2) Rinse the product obtained in the above steps, dry it, put it into a hydrothermal reaction kettle filled with polyvinylpyrrolidone, and react at 200°C for 4 hours to obtain the manganese oxyhydroxide nanowire array;

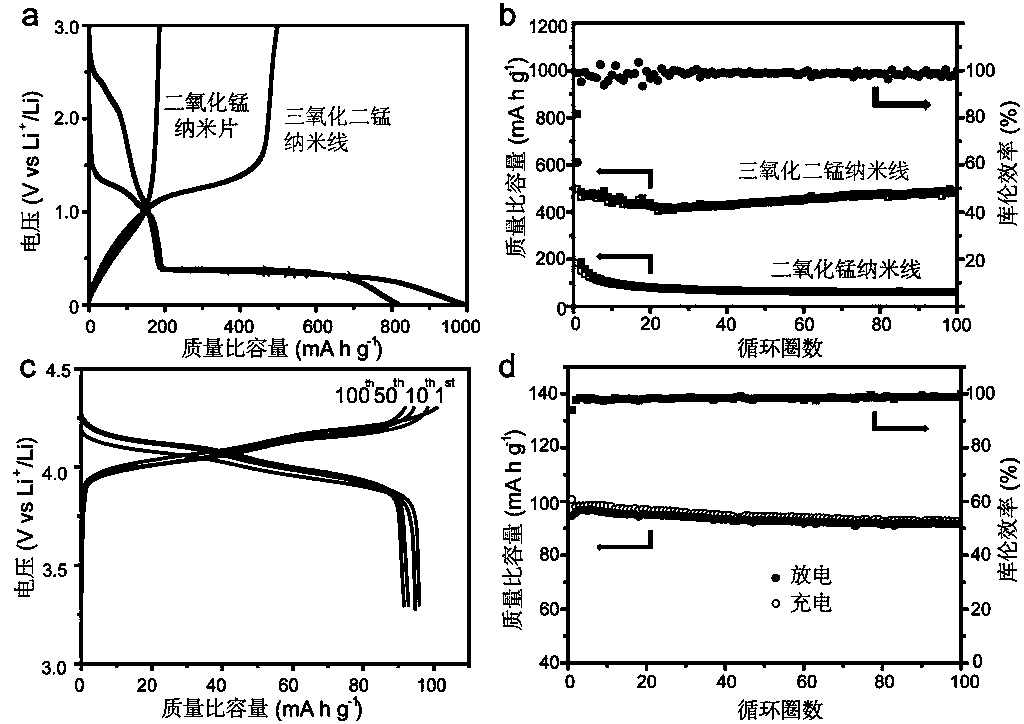

[0027] (3) Manganese oxyhydroxide nanowire arrays were calcined at 500 °C in air for 4 hours to obtain manganese trioxide nanowire arrays; after mixing manganese oxyhydroxide nanowire arrays with ethanol solution of lithium nitrate, they were calcined at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com