Method for testing shear dispersion performance of glass fibers in thermoplastic plastics

A thermoplastic and glass fiber technology, applied in the field of shear dispersion performance testing of thermoplastic glass fibers, can solve the problems of high cost, long evaluation period, and inability to reflect the shear dispersion performance of glass fibers in a timely, effective and accurate manner. Achieve accurate evaluation and overcome the effect of evaluation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

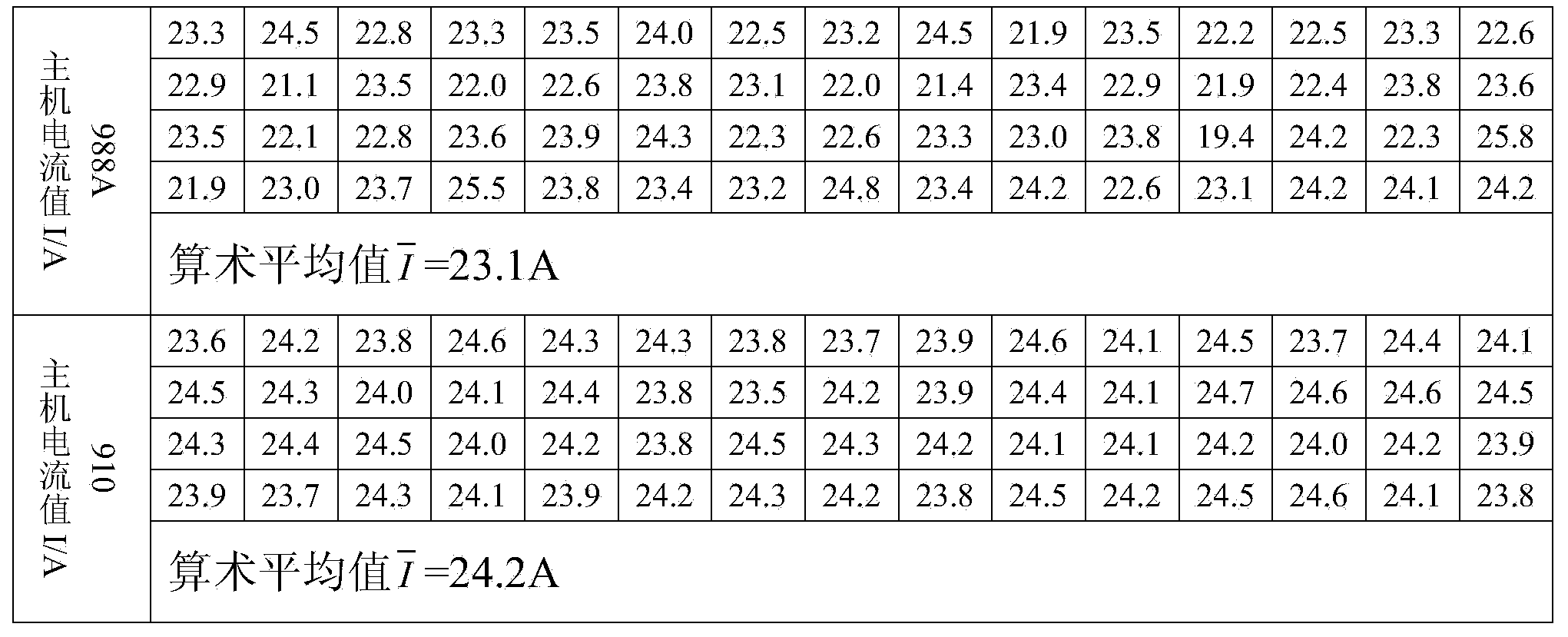

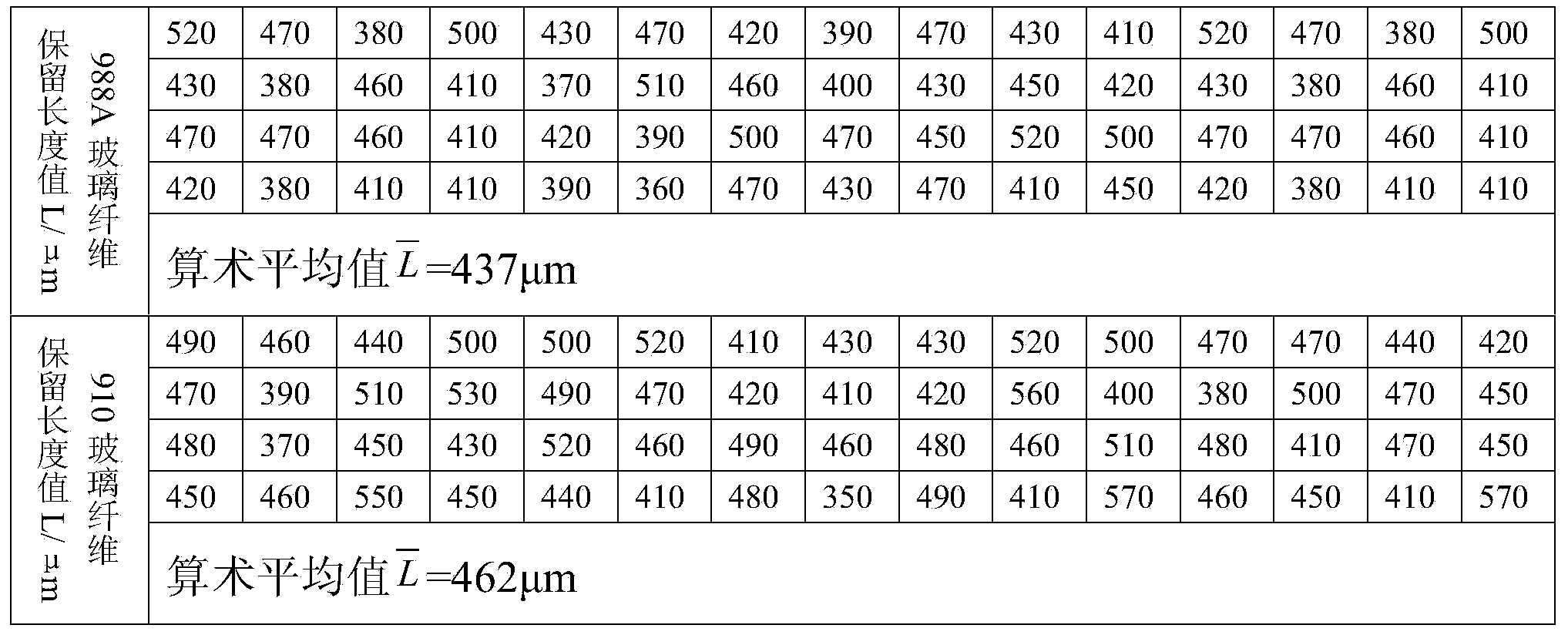

Embodiment 1

[0031] Raw materials: glass fiber: Jushi Group Co., Ltd., ER13-2000-988A; Jushi Group Co., Ltd., ER13-2000-910; thermoplastics: polypropylene (PP), Sinopec, F401, melt properties: 230 ° C load is 2.16 Under the condition of kg, the melt index is 4.02g / min;

[0032] Test conditions: temperature is 23°C, relative humidity is 50%.

[0033] Test steps:

[0034](1) According to the melt characteristics of the glass fiber to be tested and the thermoplastic to be tested, adjust the twin-screw extruder to a screw combination with appropriate shear force, and increase the temperature range of the twin-screw extruder to 210-230°C ;

[0035] (2) Put the thermoplastic in a vacuum drying oven, set the baking temperature to 80° C., and the baking time to 2 hours. After the thermoplastic slices are dried, add them to the main feeding device of the twin-screw extruder , the rotating speed of setting main screw rod is 200rpm, and the yarn feeding amount of main screw rod is 8000tex, and the...

Embodiment 2

[0045] Raw materials: glass fiber: Jushi Group Co., Ltd., ER13-2000-988A; Jushi Group Co., Ltd., ER13-2000-910; thermoplastics: polypropylene (PP), Sinopec, F401, melt properties: 230 ° C load is 2.16 Under the condition of kg, the melt index is 4.02g / min;

[0046] Test conditions: temperature is 23°C, relative humidity is 50%.

[0047] Test steps:

[0048] (1) According to the melt characteristics of the glass fiber to be tested and the thermoplastic to be tested, adjust the twin-screw extruder to a screw combination with appropriate shear force, and increase the temperature range of the twin-screw extruder to 210-230 ℃;

[0049] (2) Put the thermoplastic in a vacuum drying oven, set the baking temperature to 80° C., and the baking time to 2 hours. After the thermoplastic slices are dried, add them to the main feeding device of the twin-screw extruder , the rotating speed of setting main screw rod is 150rpm, and the yarn feeding amount of main screw rod is 6000tex, and the...

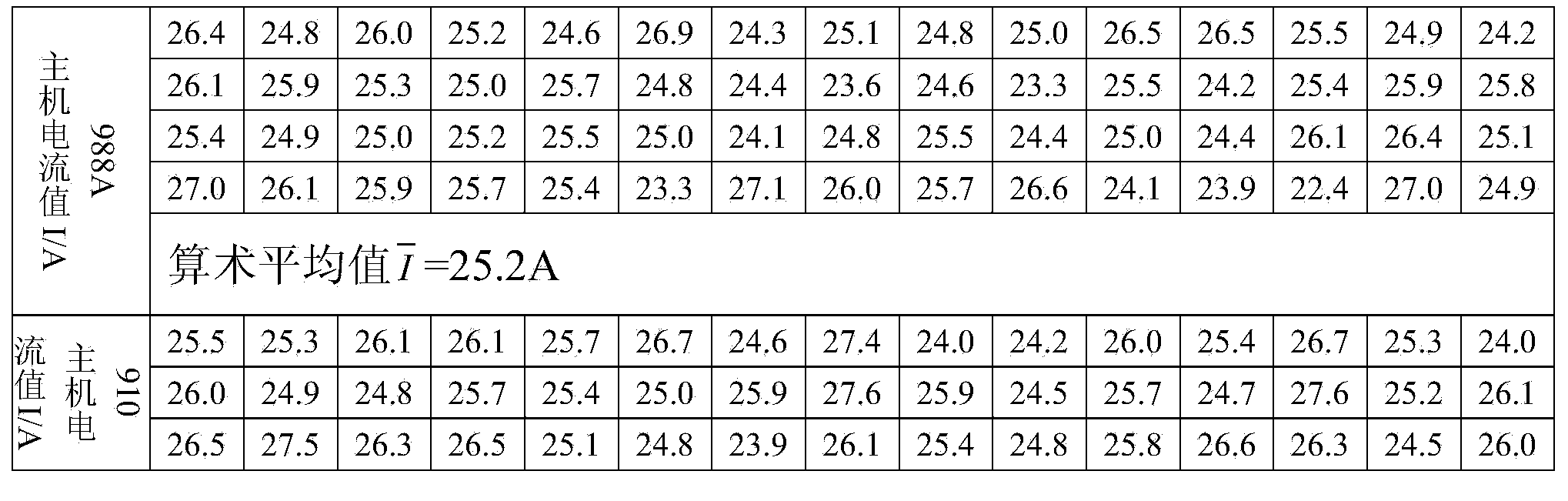

Embodiment 3

[0060] Raw materials: glass fiber: Jushi Group Co., Ltd., ER13-2000-988A; Jushi Group Co., Ltd., ER13-2000-910; thermoplastics: polypropylene (PP), Sinopec, F401, melt properties: 230 ° C load is 2.16 Under the condition of kg, the melt index is 4.02g / min;

[0061] Test conditions: temperature is 23°C, relative humidity is 50%.

[0062] Test steps:

[0063] (1) According to the melt characteristics of the glass fiber to be tested and the thermoplastic to be tested, adjust the twin-screw extruder to a screw combination with appropriate shear force, and increase the temperature range of the twin-screw extruder to 210-230 ℃;

[0064] (2) Put the thermoplastic in a vacuum drying oven, set the baking temperature to 80° C., and the baking time to 2 hours. After the thermoplastic slices are dried, add them to the main feeding device of the twin-screw extruder , the rotating speed of setting main screw rod is 300rpm, and the yarn feeding amount of main screw rod is 10000tex, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com