Device and method for filling dual process interface heat pipe with solid working mediums

A technology with dual process interfaces and process ports, which is applied in the key process field of heat pipes, can solve the problems of unfavorable influence of operators, unstable process, troublesome winding process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

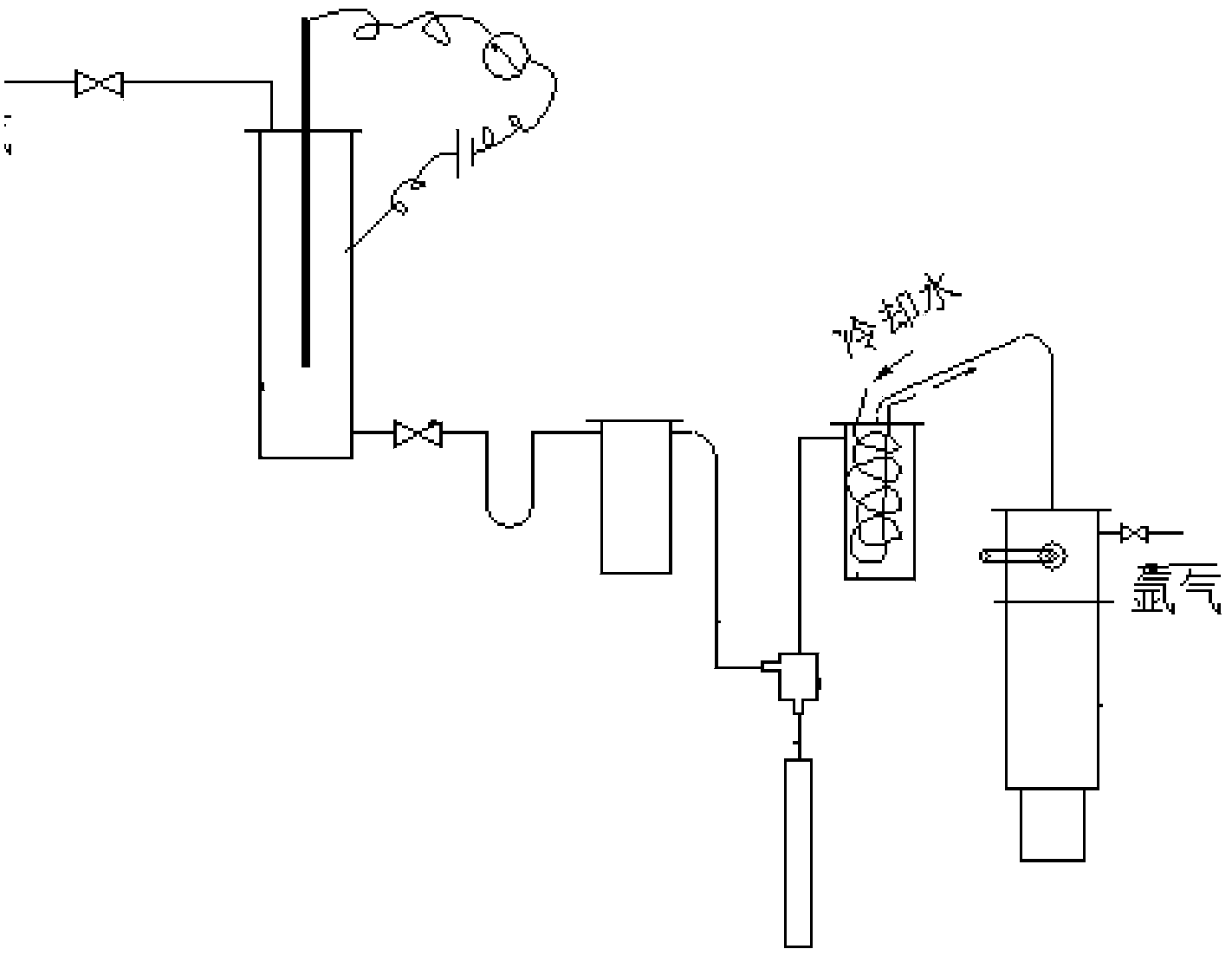

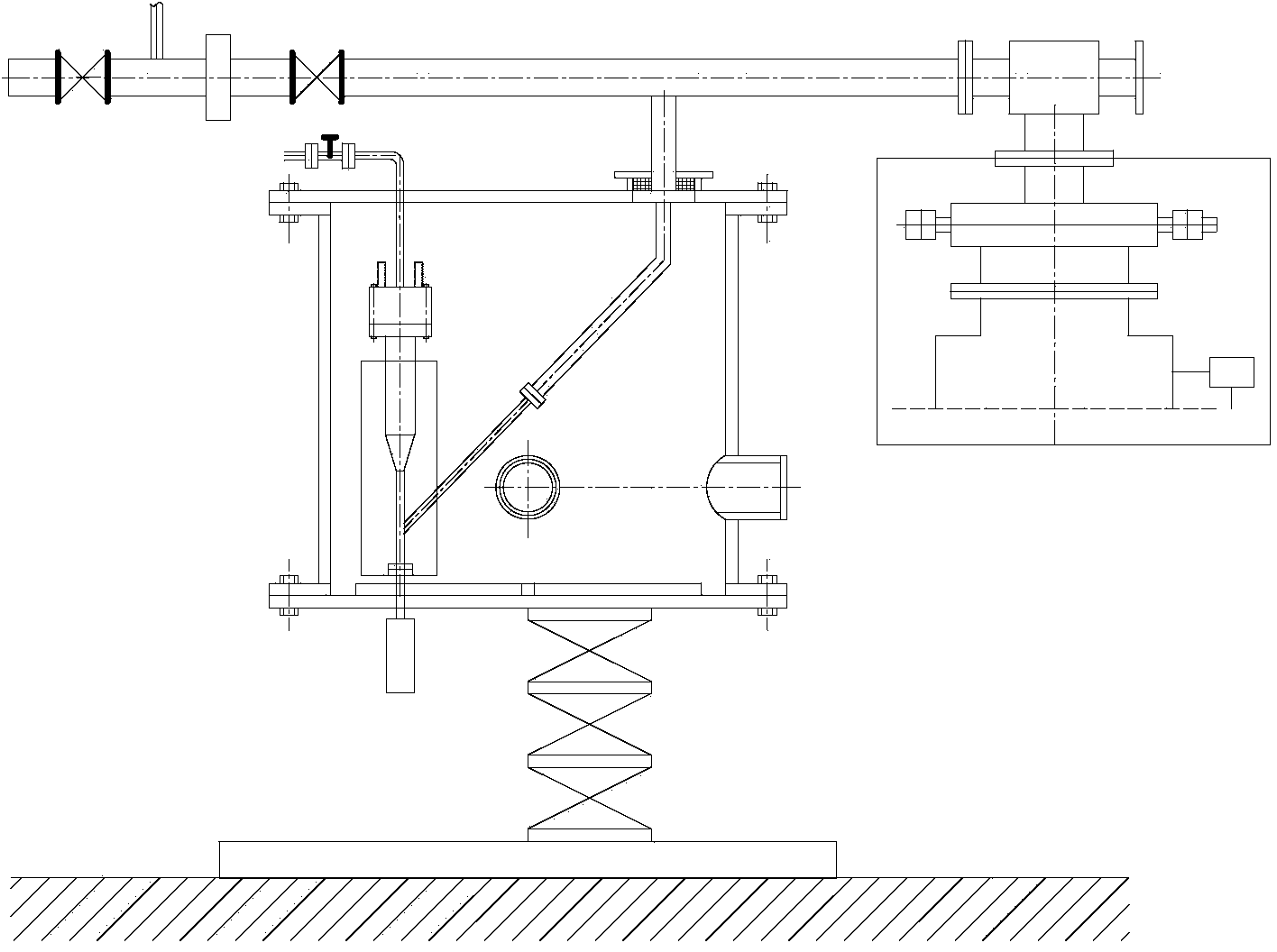

[0070] like Figure 5 Shown is a schematic structural diagram of the solid working fluid filling equipment for the heat pipe with dual process interface of the present invention. It can be seen from the figure that the solid working medium filling equipment for the heat pipe of the present invention includes a glove box 7, a working medium tank 4, an upper cover 8, and an inert gas source 31 , Vacuum molecular pump unit, heater and cooler, weighing balance 17, air pillow with eccentric hole 12, screen cylinder 13, top cover tightening mechanism 10, two cooling water semi-rings 5, sealing ring 9, screen cylinder crane Hook 14, glove box cover 15, weighing balance hook 16, air pillow valve 18, first upper inflation valve 19, trimmer valve 20, second upper inflation valve 21, upper exhaust valve 22, lower exhaust valve 23, High vacuum valve 24 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com