Manufacturing method for light diffusion sheet for improving color rendering of white LED lamp

A technology of LED lamps and light diffusers, which is applied to semiconductor devices of light-emitting elements, light sources, point light sources, etc., can solve problems such as waste, dazzling illumination angle, color distortion, etc. Color ability, improve uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for manufacturing a light diffusion plate for improving the color rendering index of ordinary white LED lamps, comprising the following steps:

[0026] (1) Mix silica gel solution, nano barium sulfate and nitride red phosphor (chemical formula: Ba 2 Si 5 N 8 : Eu) mixed. Wherein, the weight percentage of the silica gel solution is 75-94%, the weight percentage of the nanometer barium sulfate is 1-5%, and the weight percentage of the nitride red fluorescent powder is 5-20%.

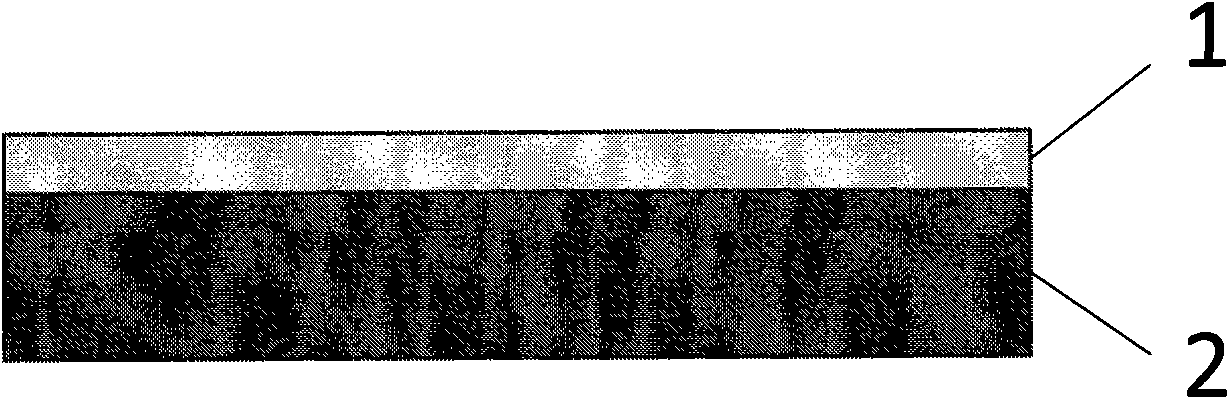

[0027] (2) Use screen printing to print the above-mentioned mixed material onto one side of the acrylic light diffusion plate substrate to obtain a spectrum adjustment layer. The schematic diagram of the side view structure is shown in figure 1 .

[0028] (3) Irradiate the prepared spectrum adjustment layer with ultraviolet light to make it solidify, so as to obtain the product.

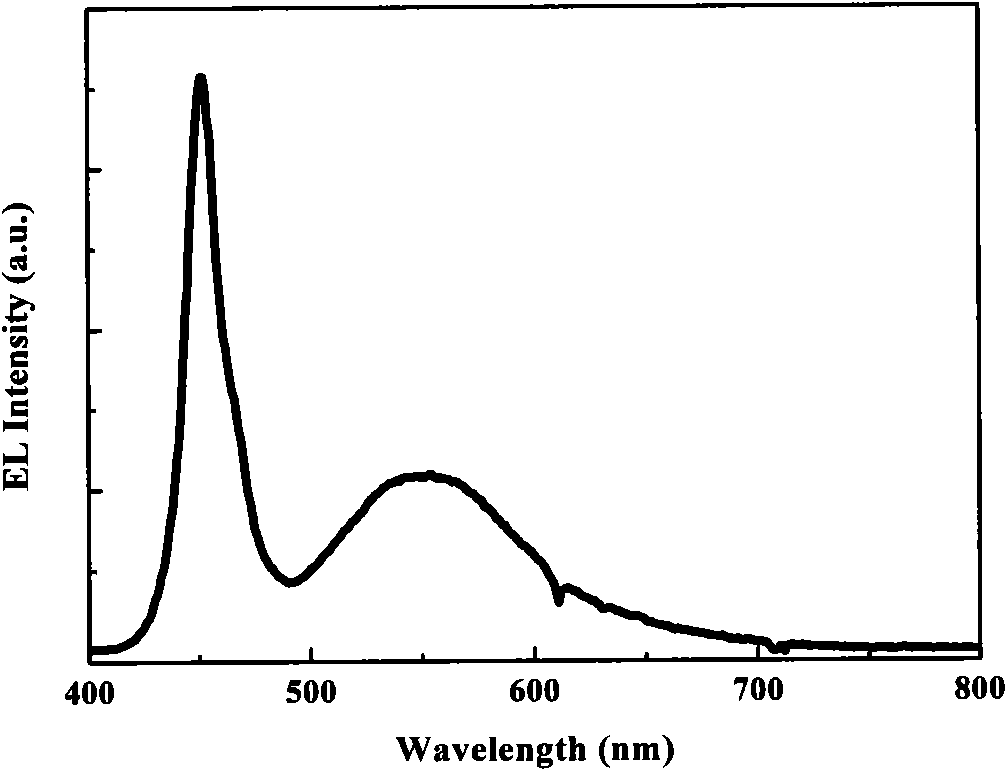

[0029] (4) Test: The luminescence spectrum of the white LED chip is as follows: image 3 As shown, its co...

Embodiment 2

[0031] A method for manufacturing a light diffusion plate for improving the color rendering index of ordinary white LED lamps, comprising the following steps:

[0032] (1) Mix silica gel solution, nano barium sulfate and nitride red phosphor (chemical formula: Ba 2 Si 5 N 8 : Eu) mixed. Wherein, the weight percentage of the silica gel solution is 75-94%, the weight percentage of the nanometer barium sulfate is 1-5%, and the weight percentage of the nitride red fluorescent powder is 5-20%.

[0033] (2) Print the above mixed material onto one side of the acrylic light diffusion plate substrate with a screen printing machine to obtain a spectrum adjustment layer.

[0034] (3) Irradiating the prepared spectrum adjustment layer with ultraviolet light to make it cured.

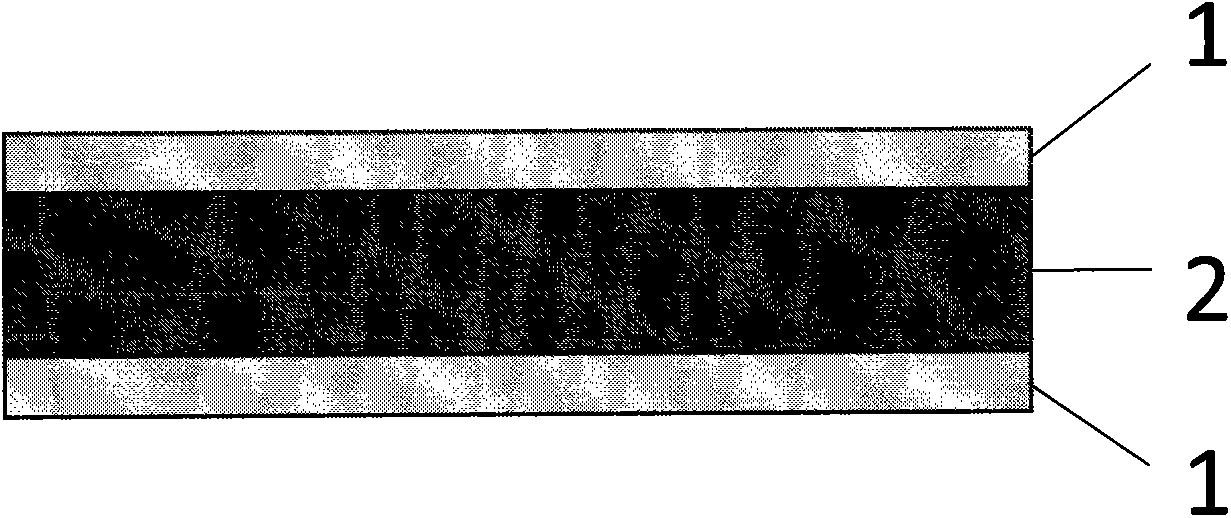

[0035] (4) Use a screen printing machine to print the spectrum adjustment layer on the other side of the above-mentioned light diffusion plate substrate. The schematic diagram of its side view structure is shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com