Inorganic gel-steel prestressed composite pipe

An inorganic gel, prestressing technology, applied in the field of transportation pipelines, can solve the problems of poor tensile, deformation and impact resistance of composite pipes, achieve excellent flame retardant and antistatic properties, improve tensile and deformation resistance, and is convenient The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

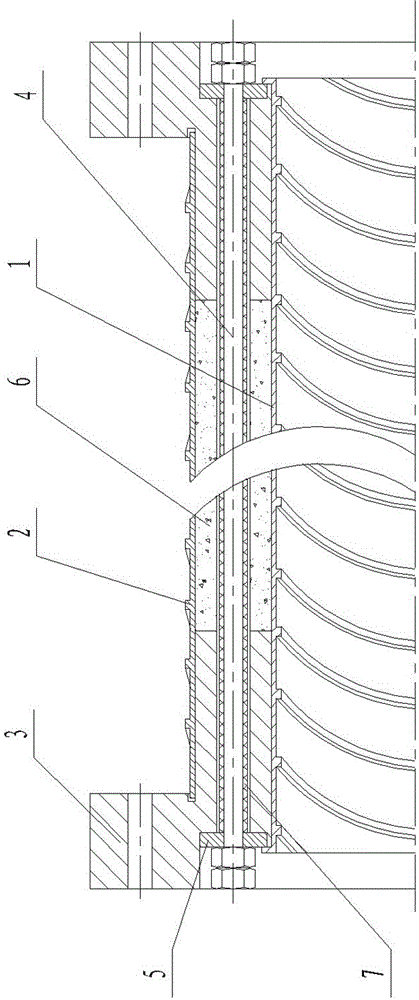

[0014] See attached figure 1 , inorganic gel-steel prestressed composite pipe, the structure includes an inner metal pipe 1, an outer metal pipe 2 and flanges 3 arranged at both ends of the inner and outer metal pipes, and inorganic gel 6 is filled between the inner and outer pipe walls. The feature is that the structure also includes prestressed tendons 4 connecting the inner and outer metal pipe ends and the flange 3 , and the prestressed tendons 4 form a prestressed adjustment mechanism with the flange 3 by means of locking components.

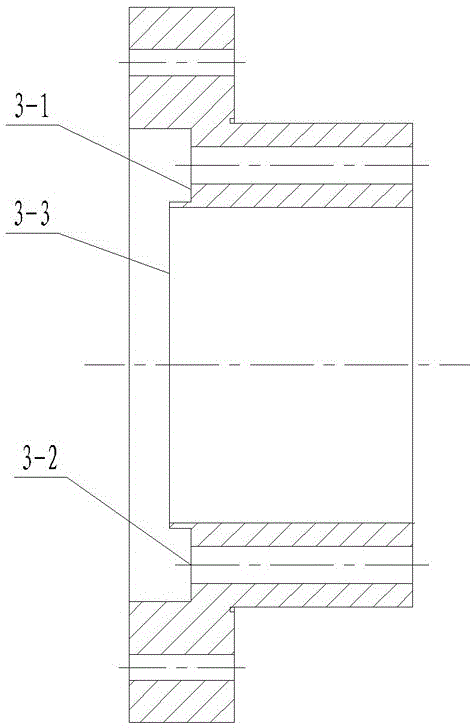

[0015] The outer end surface of the flange 3 is provided with an annular groove 3-1, and the bottom of the annular groove 3-1 is provided with a prestressed tendon hole 3-2, and 3 to 6 prestressed tendon holes are matched with the pipe diameter. The annular groove 3-1 is provided so that the locking nut is installed in the annular groove 3-1, thereby facilitating the installation of the composite pipe.

[0016] The inner end surface 3-3 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com