Portal scaffold

A portal scaffolding and scaffolding technology, which is applied in the field of scaffolding, can solve problems such as personnel injury, increased friction of universal wheels, and scaffolding rolling, so as to prevent personnel injury, enhance stability, and avoid rollover effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

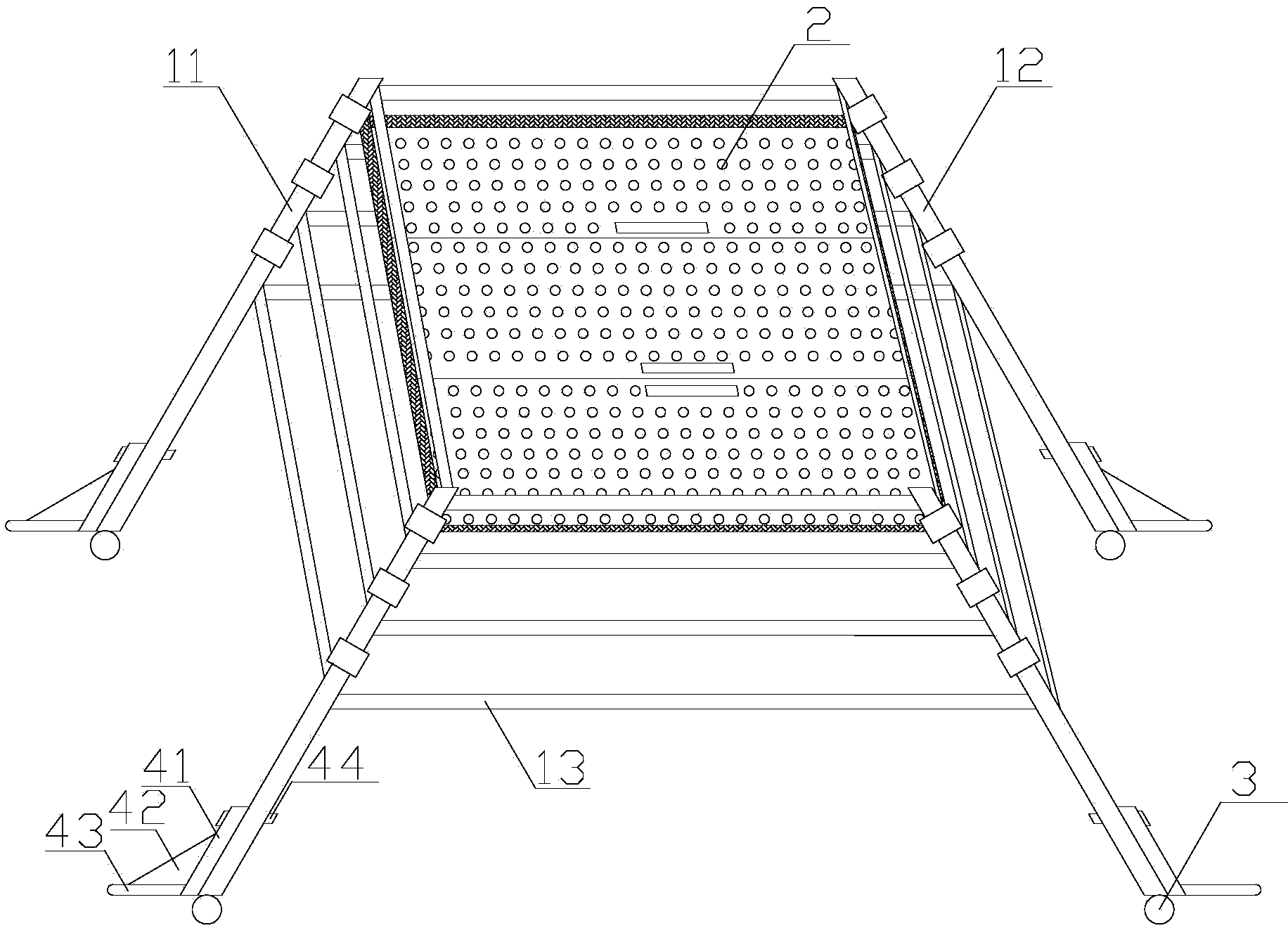

[0013] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a portal scaffold proposed by the present invention.

[0014] refer to figure 1 , a portal scaffold proposed by the present invention includes a frame, a platform mechanism 2, universal wheels 3 and a fixing mechanism.

[0015] The frame includes a first rod 11, a second rod 12 and a third rod 13, the angle α is formed between the first rod 11, the second rod 12 and the ground, 55°≤α≤75°, and the third rod 13 is parallel Set on the ground, adjacent first rods 11 and second rods 12 are fixedly connected by a third rod 13 to form a door frame A, and two adjacent first rods 11 are fixedly connected by a third rod 13 to form a door frame B. The two second rods 12 are fixedly connected by the third rod 13 to form a door frame C, any two door frames A are parallel to each other, and the door frame B and the door frame C form an angle β, 30°≤β≤55°, the first rod The lower part of 11 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com