Oil-filled and carbon nano tube filled emulsion coprecipitated rubber and preparation method thereof

A carbon nanotube and emulsion co-precipitation technology, applied in the field of polymer-based nanocomposite materials, can solve the problems of difficult to achieve industrialized production, carbon nanotube residues, poor composite material performance, etc., and achieve easy industrialization, excellent antistatic performance, Actionable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

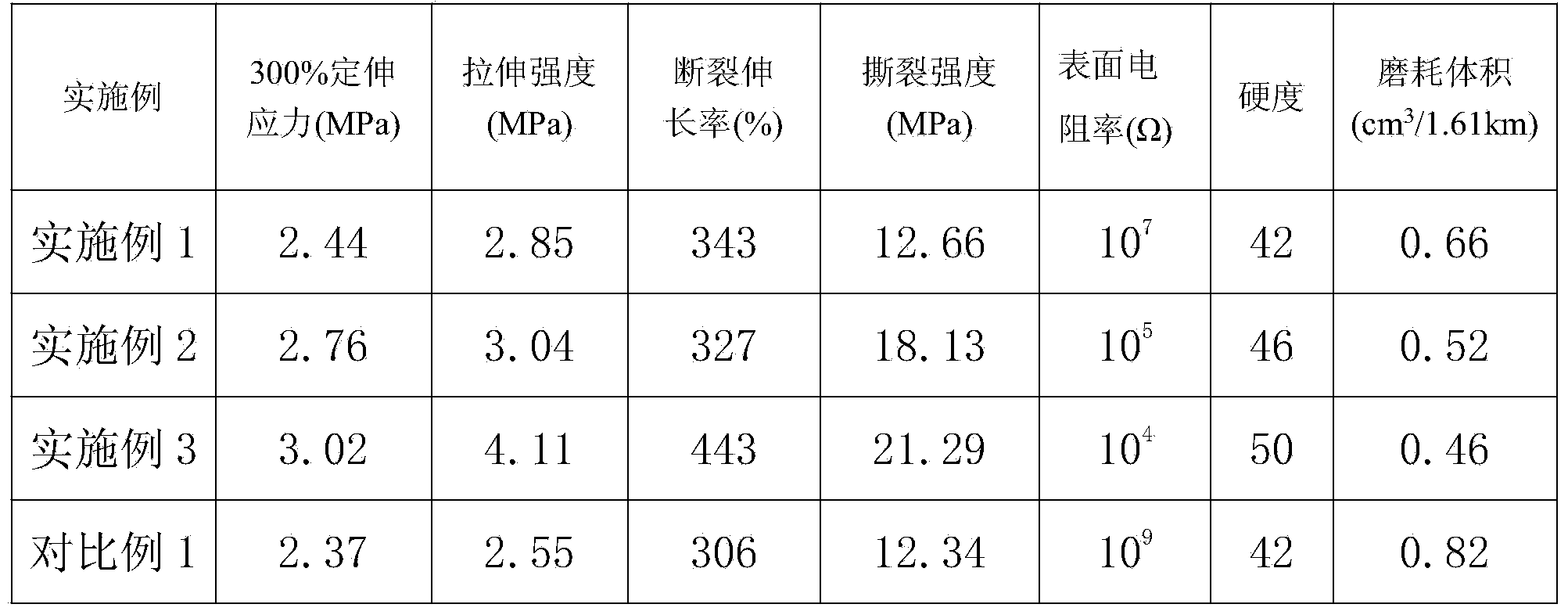

Examples

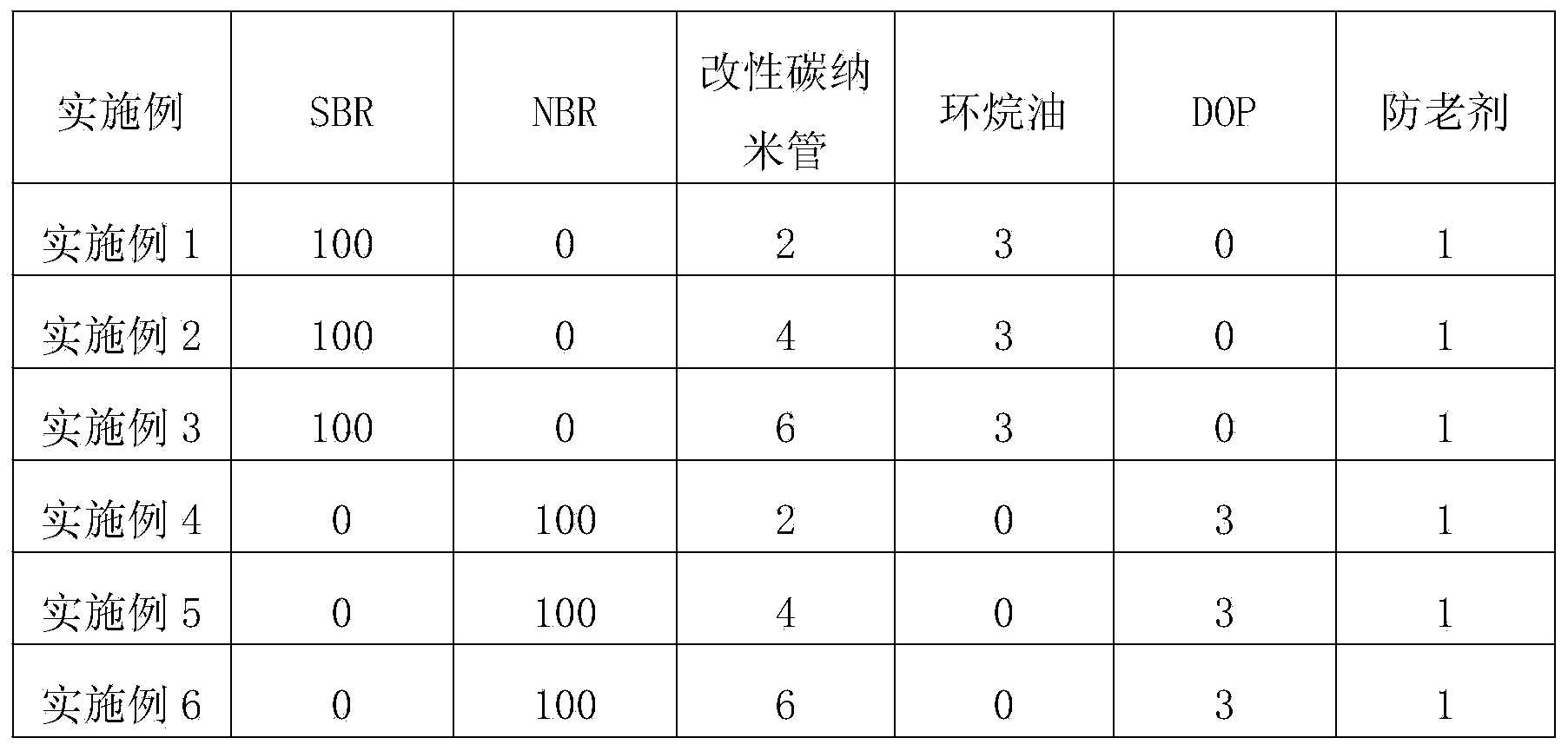

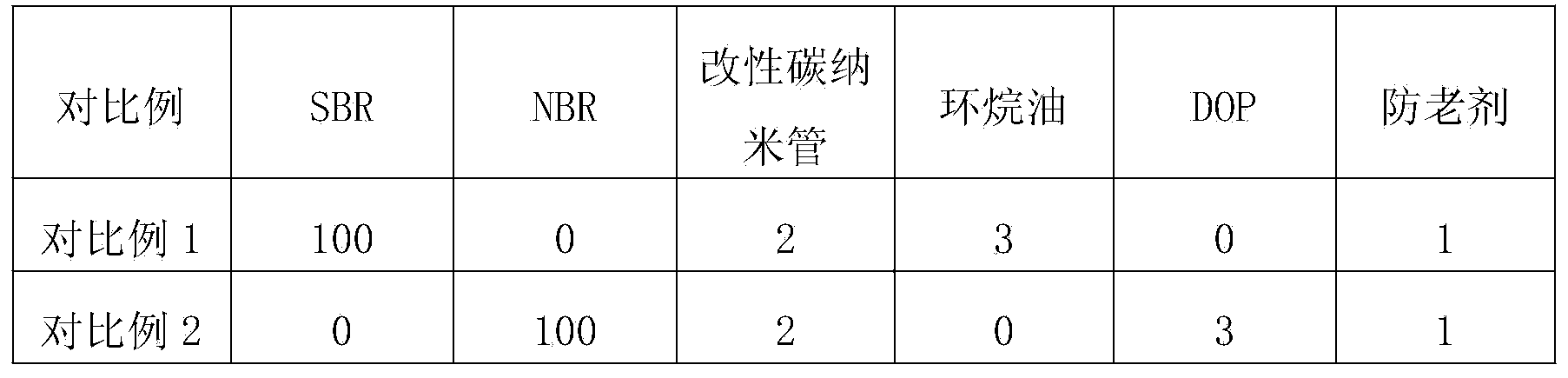

Embodiment 1-6

[0022] Embodiment 1-6: Taking naphthenic oil-filled carbon nanotube emulsion co-precipitation styrene-butadiene rubber and DOP-filled carbon nanotube emulsion co-precipitation nitrile rubber as examples, the oil-filled carbon nanotube emulsion co-precipitation rubber of the present invention is illustrated preparation method and properties.

[0023] (1) Preparation of modified carbon nanotube suspension: multi-walled carbon nanotubes and water are made into a suspension of 10wt% concentration, and the modifier vinylbenzenetrimethyl chloride of carbon nanotube quality 1wt% is added thereto ammonium chloride, stirred and reacted at 60° C. for 1 hour; then sodium dodecylbenzenesulfonate with 2 wt % carbon nanotube mass was added thereto, and stirring was continued for 10 minutes to prepare a modified carbon nanotube suspension.

[0024] (2) Preparation of emulsified oil: uniformly mix naphthenic oil or DOP with water and emulsifier, disperse at 60° C. for 30 minutes in a high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com