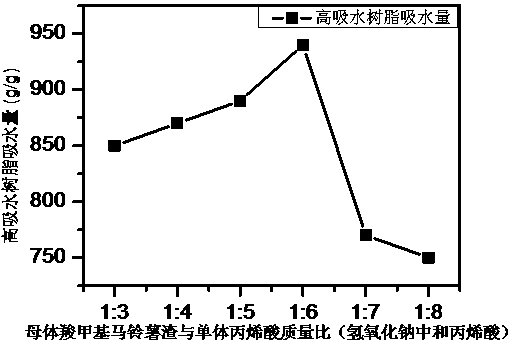

Method for synthesizing super absorbent resin by graft polymerization of carboxymethyl potato pulp

A technology of super absorbent resin and potato residue, applied in the field of synthesizing super absorbent resin, can solve problems such as environmental pollution, waste of resources, etc., and achieve the effects of low reaction temperature and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

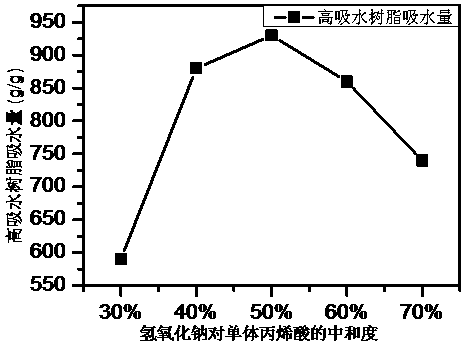

Embodiment 1

[0024] Example 1: Weigh 3.47g sodium hydroxide (or 4.86g potassium hydroxide), dissolve it in 20.00ml deionized water, weigh 12.50g (11.90ml) acrylic acid, and dissolve sodium hydroxide (or hydroxide Potassium) solution was added dropwise to the above-mentioned acrylic acid, and kept stirring until the neutralization was completed and no heat was generated. Weighed 2.50g of carboxymethyl potato residues and mixed them with 30ml of deionized water evenly, and mixed the neutralized acrylic acid and its salt solution with Mix the carboxymethyl potato residue mixture evenly, add it to the reaction flask, and add 200 mg potassium persulfate, 154 mg sodium bisulfite, 30 mg N, N'-methylenebisacrylamide into the reaction flask, and then blow nitrogen into it. Slowly heat to increase the temperature of the reaction system gradually. When the polymerization reaction starts at 25-30°C, stop stirring and continue to feed nitrogen gas, gradually raise the temperature to 90°C and keep it at ...

Embodiment 2

[0025] Example 2: Weigh 5.83g sodium hydroxide (or 5.83g potassium hydroxide), dissolve it in 20.00ml deionized water, weigh 15.00g (14.30ml) acrylic acid, and dissolve sodium hydroxide (or hydroxide Potassium) solution was added dropwise to the above-mentioned acrylic acid, and kept stirring until the neutralization was completed and no heat was generated. Weighed 2.50g of carboxymethyl potato residues and mixed them with 30ml of deionized water evenly, and mixed the neutralized acrylic acid and its salt solution with Mix the carboxymethyl potato residue mixture evenly, add it into the reaction flask, and add 100mg of potassium persulfate, 77mg of sodium bisulfite, 35mg of N,N'-methylenebisacrylamide into the reaction flask. Heating to increase the temperature of the reaction system gradually. When the polymerization reaction starts at 40-45°C, stop stirring and continue to introduce nitrogen gas. Gradually raise the temperature to 90°C and keep it at this temperature for 2 ho...

Embodiment 3

[0026] Embodiment 3: Weigh 6.80g sodium hydroxide (or 6.80g potassium hydroxide), dissolve it in 20.00ml deionized water, weigh 17.50g (16.70ml) acrylic acid, and dissolve sodium hydroxide (or hydroxide Potassium) solution was added dropwise to the above-mentioned acrylic acid, and kept stirring until the neutralization was completed and no heat was generated. Weighed 2.50g of carboxymethyl potato residues and mixed them with 30ml of deionized water evenly, and mixed the neutralized acrylic acid and its salt solution with Mix the carboxymethyl potato residue mixture evenly, add it to the reaction flask, and add 175mg of potassium persulfate, 134.75mg of sodium bisulfite, 30mg of N, N'-methylenebisacrylic acid into the reaction flask. Heating to increase the temperature of the reaction system gradually. When the polymerization reaction starts at 30-35°C, stop stirring and continue to feed nitrogen gas, gradually increase the temperature to 90°C and keep it at this temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com