Method for synthesizing high water absorbent polymer by using potato starch xanthate and acrylamide

A technology of potato starch and superabsorbent resin, applied in the field of simple preparation, can solve the problems of low water absorption, complex production process, high production cost, etc., achieve high water absorption, low polymerization reaction temperature, and reduce energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

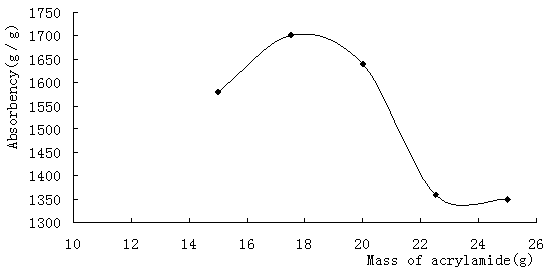

Image

Examples

Embodiment 1

[0037] Example 1: Weigh 3.94g sodium hydroxide, dissolve it in 52.5ml deionized water, weigh 17.5g acrylamide, add acrylamide to the above sodium hydroxide solution, stir at room temperature to hydrolyze acrylamide, weigh 2.5 g Potato starch xanthate and 30ml deionized water are mixed uniformly, the hydrolyzed solution of acrylamide and the potato starch xanthate mixture are mixed uniformly, and 8ml potassium persulfate solution with a concentration of 10mg / ml and 10ml with a concentration of 2mg are added / ml of N,N'-methylene bisacrylamide solution, flow in nitrogen, slowly heat to gradually increase the temperature of the reaction system, take out the product after reaching 60°C, dry and pulverize to obtain super absorbent resin, this example The water absorption capacity of the prepared super absorbent resin in 2500 times deionized water is 1590 g / g.

Embodiment 2

[0038] Example 2: The synthesis conditions are the same as in Example 1, except that 2.95g of sodium hydroxide is weighed, dissolved in 52.5ml of deionized water, 17.5g of acrylamide is weighed, and the acrylamide is added to the above sodium hydroxide solution. Stir at room temperature to hydrolyze acrylamide. The water absorption capacity of the super absorbent resin prepared in this example in 2500 times deionized water is 1700 g / g.

Embodiment 3

[0039] Example 3: The synthesis conditions are the same as in Example 1, except that 2.95g of sodium hydroxide is weighed, dissolved in 52.5ml of deionized water, 17.5g of acrylamide is weighed, and the acrylamide is added to the above sodium hydroxide solution. Stir at room temperature to hydrolyze acrylamide, and add 10 ml of potassium persulfate solution with a concentration of 10 mg / ml. The water absorption capacity of the super absorbent resin prepared in this example in 2500 times deionized water is 1590 g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com