A kind of preparation method of 2-chloro-1,1,1,4,4,4-hexafluoro-2-butene

A technology for hexachlorodibutene and butene is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., and can solve the problems of harsh reaction conditions, unobtainable raw materials, difficult purification, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

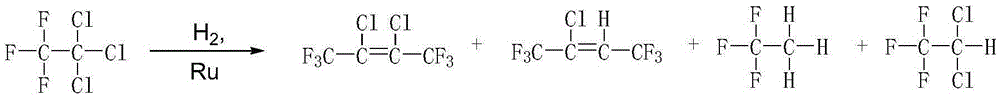

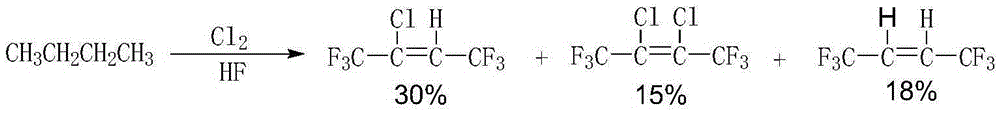

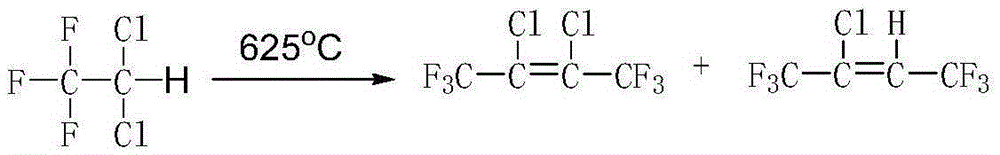

Method used

Image

Examples

Embodiment 1

[0032] Add 30g (0.10mol) antimony pentachloride and 400g (20mol) hydrogen fluoride to a 1.0L autoclave respectively, stir, then add 260.8g (1.0mol) hexachlorodibutene at a rate of 2.0g / min with a metering pump . After the addition of hexachlorodibutene, react at 80°C for 6 hours, control the reaction pressure to 1.0Mpa to cool, after the reaction, pour the reaction solution into 1200g ice water, separate layers, wash the organic layer with water, and then use 200g After washing with saturated sodium bicarbonate solution and rectifying, 180.1 g (0.91 mol) of 2-chloro-1,1,1,4,4,4-hexafluoro-2-butene with a content of 99% was obtained, yield 91% .

Embodiment 2

[0034] Add 38g (0.2mol) titanium tetrachloride and 200g (10mol) hydrogen fluoride respectively in a 1.0L autoclave, stir, then add 260.8g (1.0mol) hexachlorodibutene at a speed of 2.0g / min with a metering pump . After the addition of hexachlorodibutene, react at 120°C for 8 hours, control the reaction pressure to 2.0Mpa to cool, after the reaction, add the reaction solution into 1200g ice water, separate layers, wash the organic layer with water, and then use 200g carbonic acid After washing with a saturated sodium hydrogen solution, rectification gave 184.1 g (0.93 mol) of 2-chloro-1,1,1,4,4,4-hexafluoro-2-butene with a content of 99%, with a yield of 93%.

Embodiment 3

[0036] Add 38g (0.05mol) tin tetrachloride and 600g (30mol) hydrogen fluoride respectively in a 1.0L autoclave, stir, then add 260.8g (1.0mol) hexachlorodibutene at a rate of 2.0g / min with a metering pump . After the addition of hexachlorodibutene, react at 160°C for 10 hours, control the reaction pressure to 0.5Mpa, cool down, add the reaction solution to 1200g of ice water, separate layers, wash the organic layer with water, and then use 200g of carbonic acid After washing with a saturated sodium hydrogen solution, rectification gave 182.3 g (0.92 mol) of 2-chloro-1,1,1,4,4,4-hexafluoro-2-butene with a content of 99%, with a yield of 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com