Radial-flow air-flotation thickening apparatus for sludge

A thickening device and sludge thickening technology, applied in the direction of dewatering/drying/concentrating sludge treatment, can solve the problems of complex structure, small processing capacity and high cost, and achieve the effect of good concentration effect, continuous and stable operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to solve the problems of conventional sludge concentration equipment, such as small processing capacity, difficulty in applying to large-scale sludge treatment plants, complex equipment, high failure rate, and unsatisfactory concentration effect, the present invention provides a radial flow sludge air flotation concentration device , The system has the following outstanding advantages: self-flowing mud, low cost, low operating cost, good concentration effect, easy maintenance, continuous and stable operation, and non-stop maintenance. Describe in detail below by embodiment.

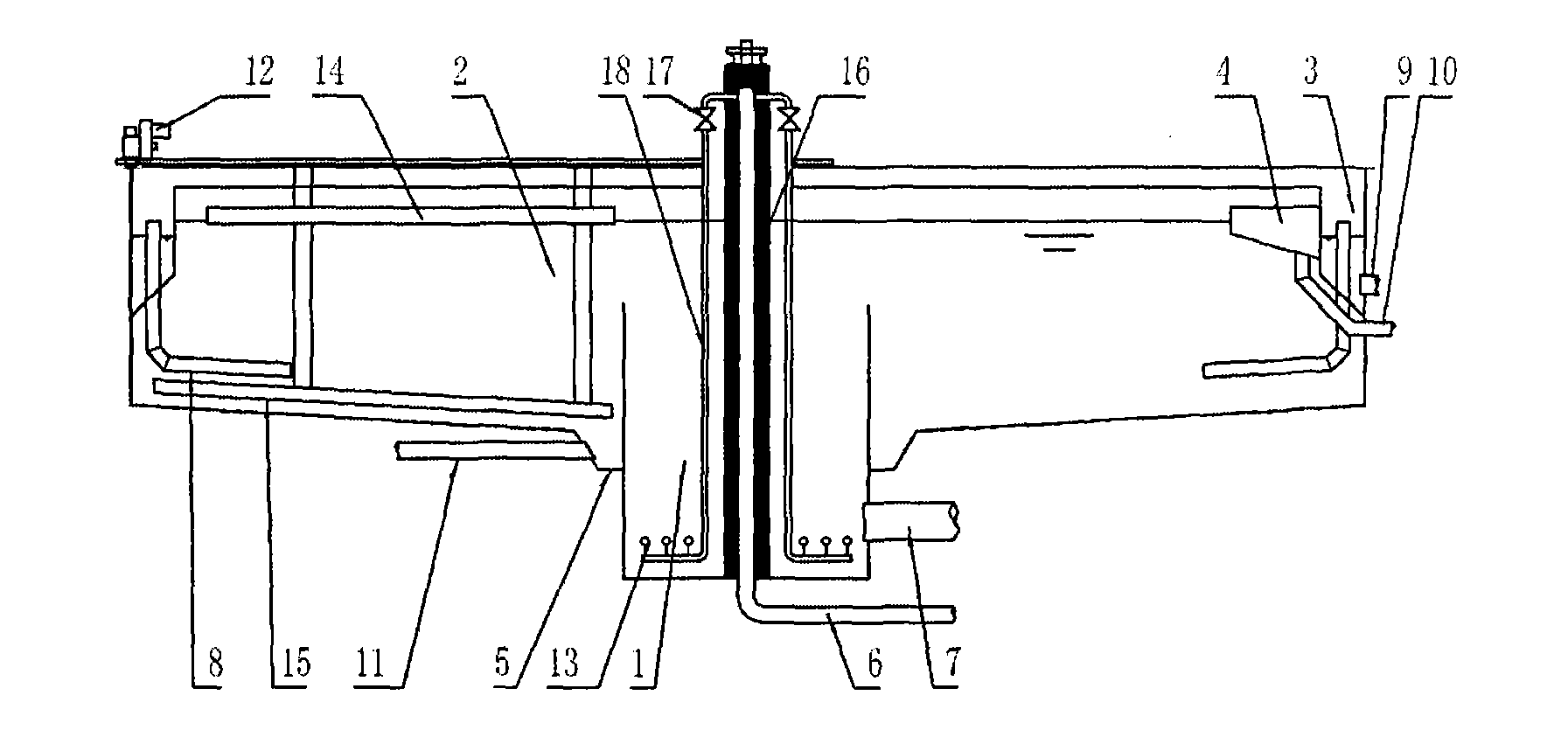

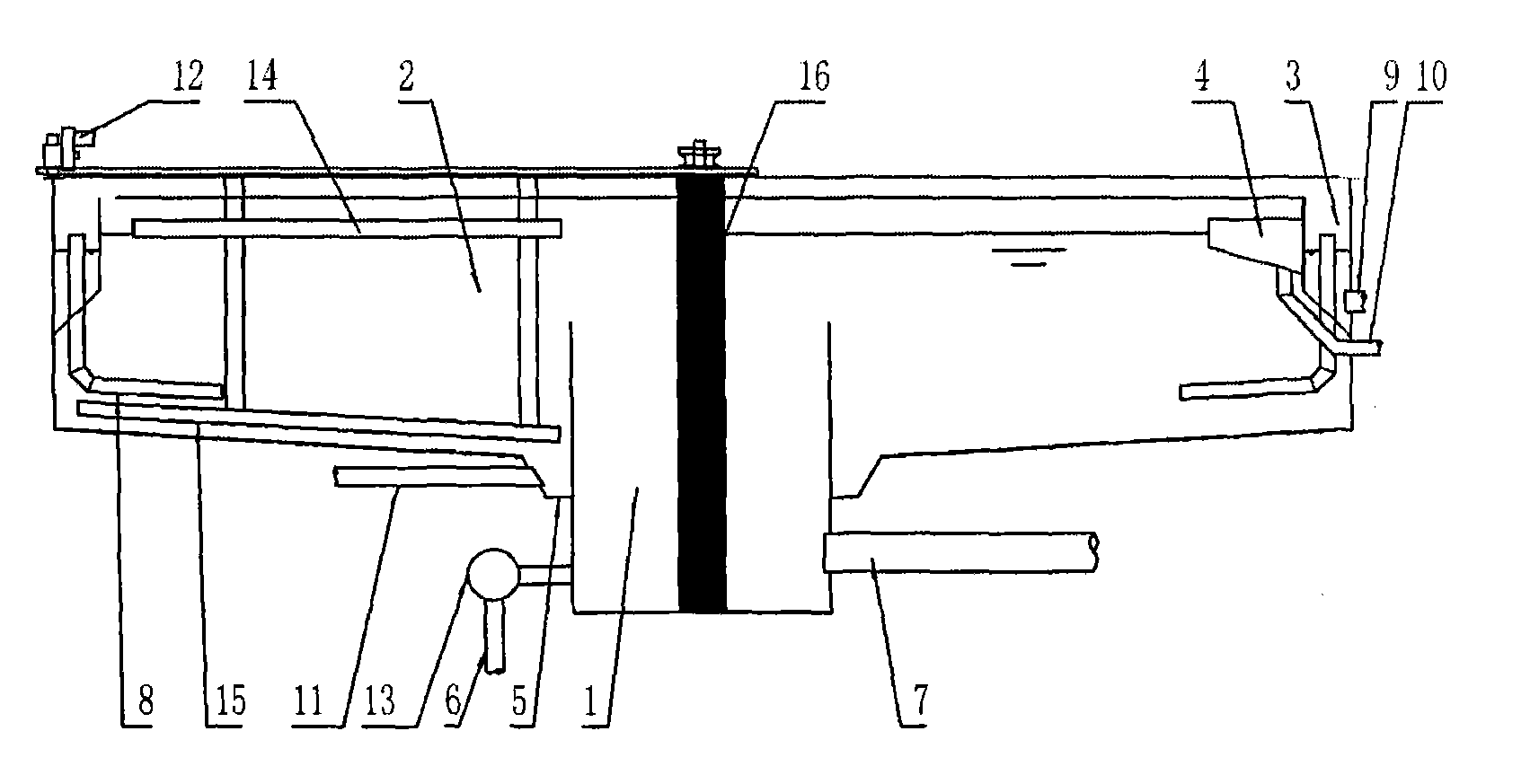

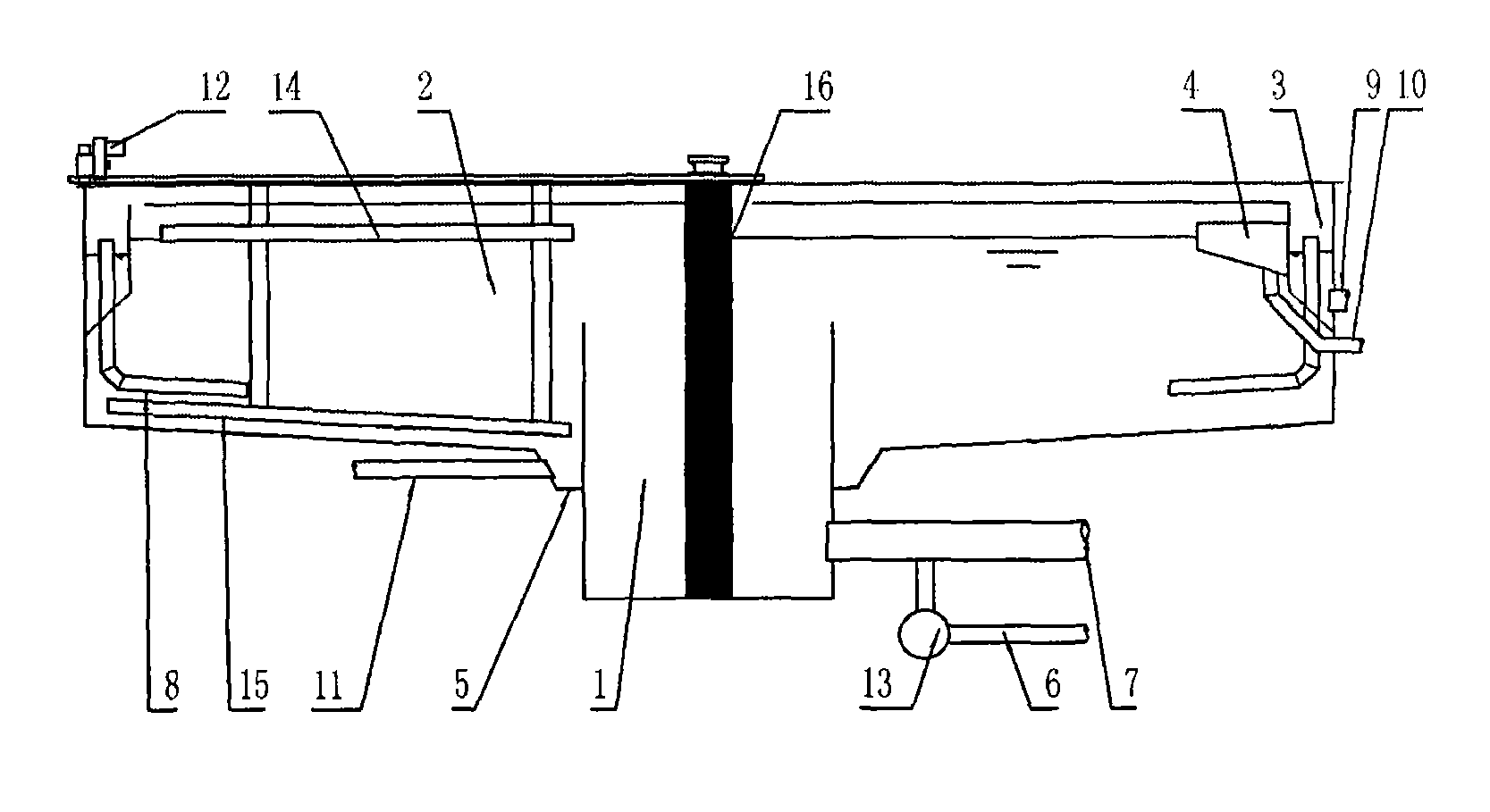

[0026] The radial flow sludge air flotation concentration device of the present invention consists of a contact area 1, a separation area 2, an outlet channel 3, a scum tank 4, a sludge tank 5, a dissolved air water inlet pipe 6, a water inlet pipe 7, and an outlet water collection pipe 8 , outlet pipe 9, slag discharge pipe 10, mud discharge pipe 11, mud scraper and slag scraper 12, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com