an oil drill

A technology for oil drill pipes and drill pipes, applied in the direction of drill pipes, drill pipes, drilling tools, etc., can solve the problems of increasing the burden on workers, single fixing function of the drill pipe fixing seat, troubles, etc., to achieve reduced labor, rich functions, The effect of improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the present invention will be further explained in conjunction with specific implementations below.

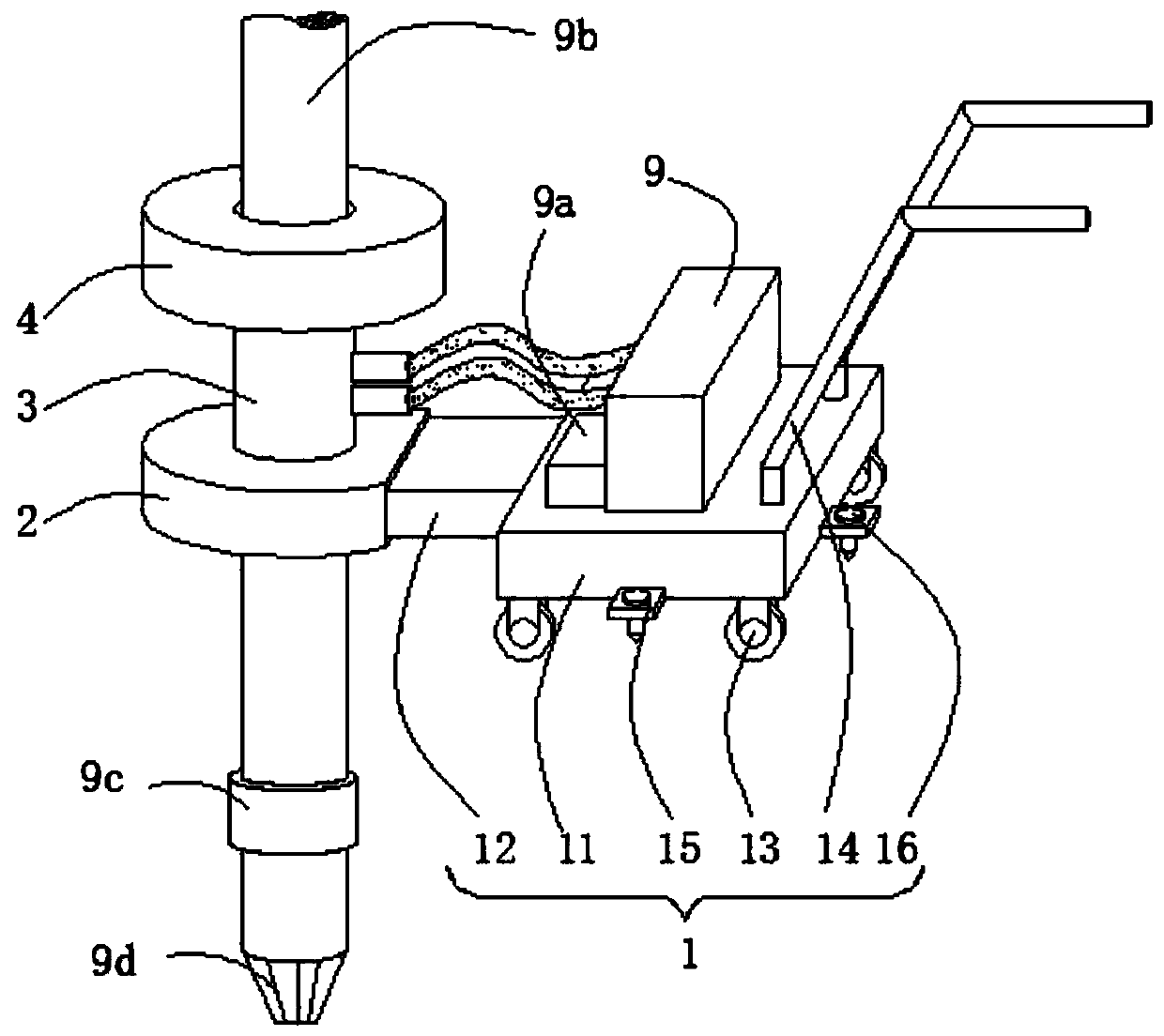

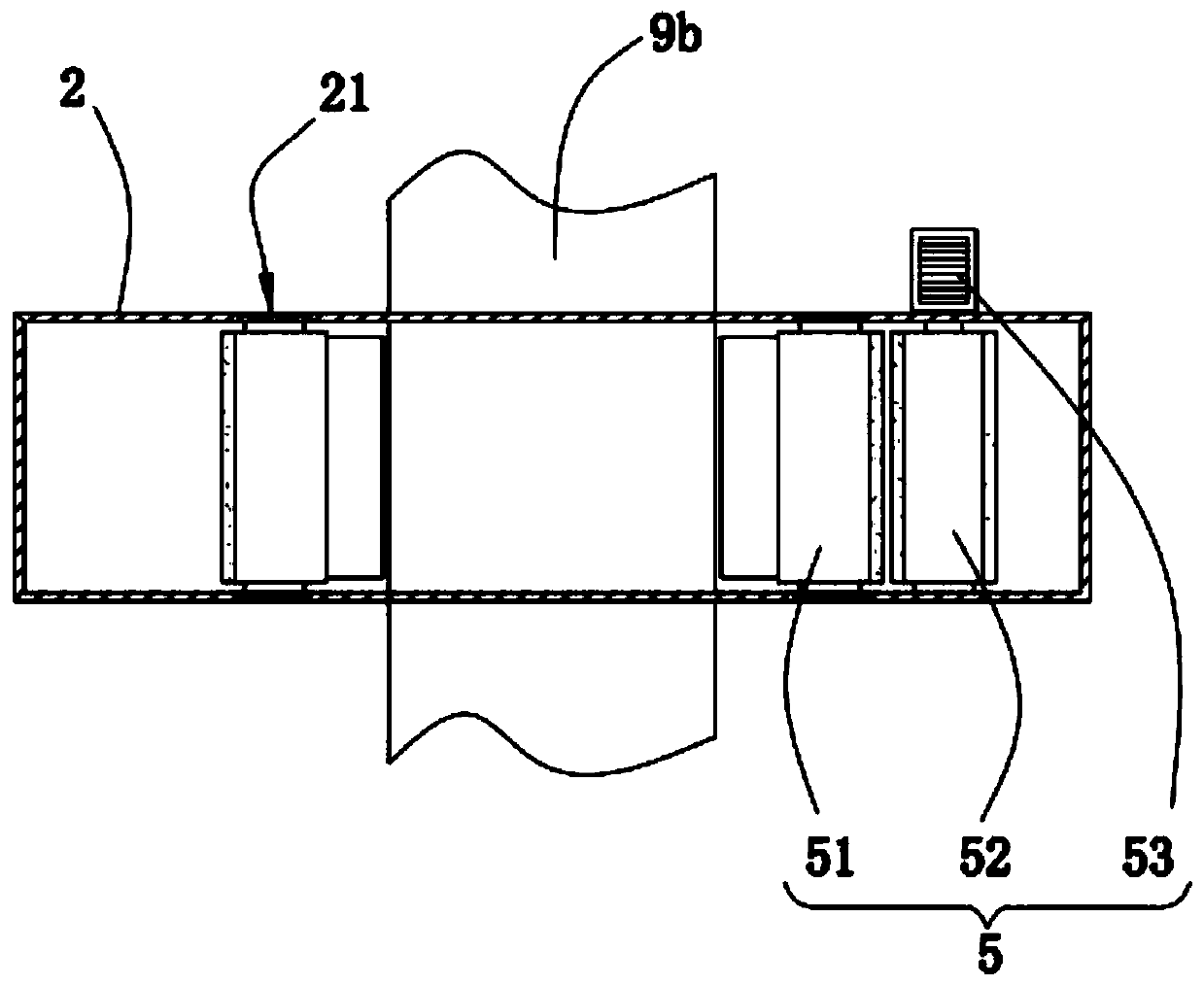

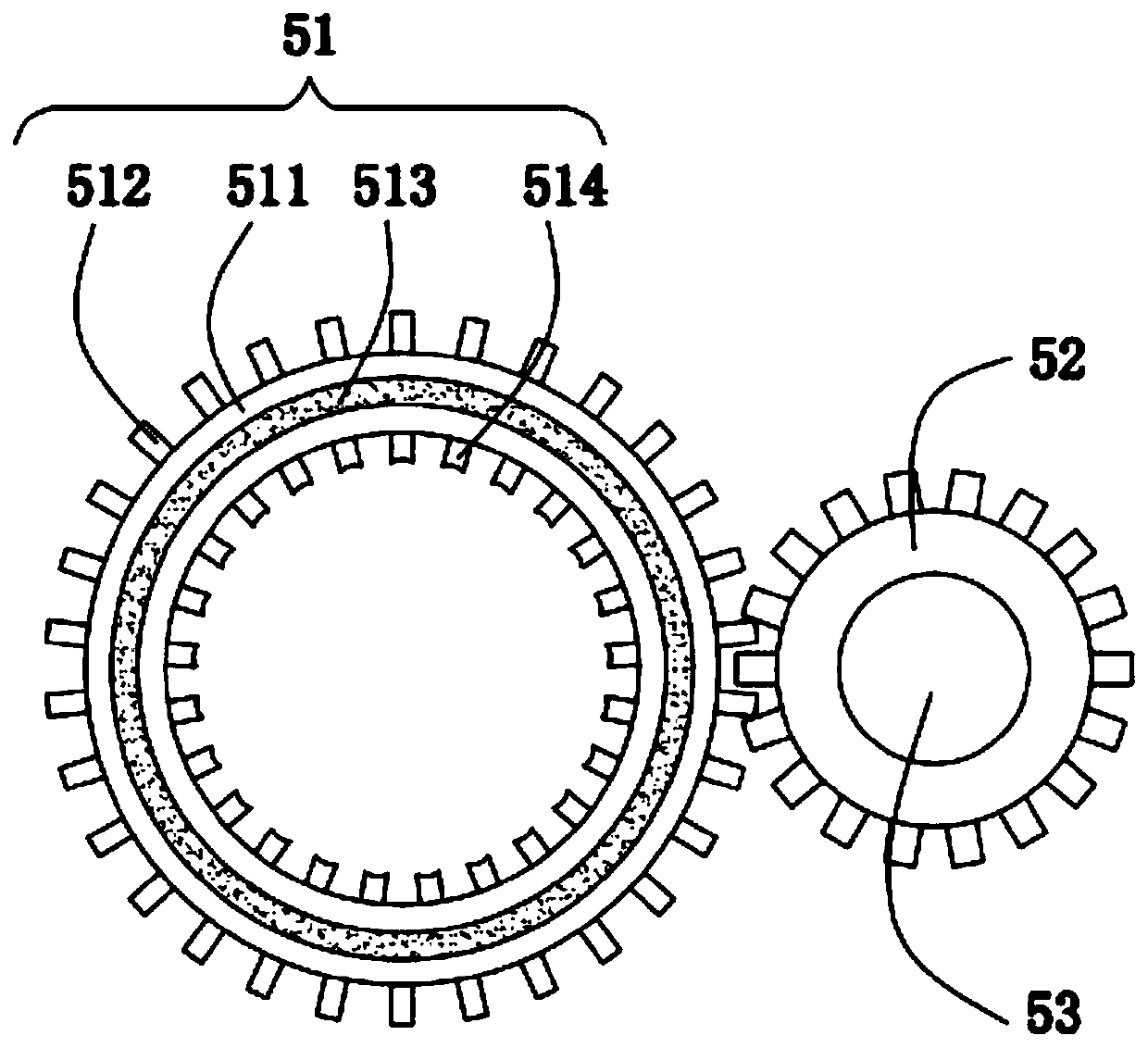

[0030] Such as Figure 1-Figure 5 As shown, an oil drill pipe according to the present invention includes a drill pipe main body 9b, a conversion joint 9c, and a drill bit 9d. The bottom end of the drill pipe main body 9b is connected with a drill bit 9d through the conversion joint 9c; it also includes a transport mechanism 1. , The first fixing seat 2, the connecting pipe 3, the second fixing seat 4, the cleaning mechanism 5, the water washing mechanism 6, the lubricating mechanism 7, the air drying mechanism 8, the box body 9 and the power supply box 9a; the transportation mechanism 1 is fixedly connected to the The first fixing seat 2; the cleaning mechanism 5 is installed inside the first fixing seat 2; the top of the first fixing seat 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com