Belt filter press

A technology of belt filter press and filter belt, which is applied in the direction of special treatment targets, water/sludge/sewage treatment, sludge treatment, etc., and can solve the problem of poor fluidity, affecting the service life of the filter belt, loss of fluidity, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

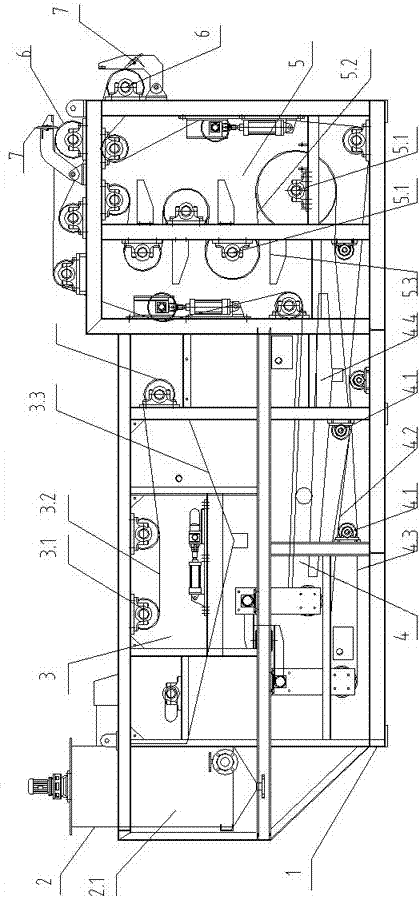

[0014] A belt filter press, mainly comprising a frame 1, a flocculation zone 2, a concentrated dehydration zone 3, a gravity dehydration zone 4 and a press dehydration zone 5, the flocculation zone 2 is equipped with a flocculation mixer 2.1; the concentration dehydration zone 3 It includes several horizontally arranged drive rollers 3.1 and a concentration filter belt 3.2 arranged on the drive roller 3.1; the mud outlet of the flocculation mixer 2.1 is located above the concentration filter belt 3.2; the gravity dehydration zone 4 is located below the concentration dehydration zone 3, The gravity dehydration zone 4 includes several arc-shaped pinch rolls 4.1, upper filter belt 4.2 and lower filter belt 4.3 fixed on the frame 1 and arranged obliquely; Squeeze filter belt 5.2, the press filter belt 5.2 is an integrated filter belt formed by connecting the upper filter belt 4.2 and the lower filter belt 4.3, the rear part of the press roll 5.1 is also provided with a desilting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com