Automobile enhanced roof soundproof pad in composite layer structure

A composite layer and sound insulation pad technology, which is applied in the direction of synthetic resin layered products, laminated, layered products, etc., can solve the problems of roof reinforcement, heavy weight, and lack of sound insulation pads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of composite laminated roof reinforced sound insulation pad for automobiles, the sound insulation pad is a three-layer composite structure, and its structure is as follows figure 1 As shown, the upper and lower layers are surface-coated kraft paper layer 1, with a grammage of 200g / m 2 , the coating is 20g / m 2 , kraft paper coated with PE film on both sides, the middle layer is 50kg / m 3 High-density polyurethane sound insulation material layer 2, thickness 8mm. The high-density polyurethane sound-insulating material layer 2 is polyurethane semi-rigid foam, and the weight ratio of polyether and isocyanate is 80:20. After stirring and mixing, it is foamed, and then cut to obtain a high-density sound-insulating material layer with a uniform thickness of 8 mm.

Embodiment 2

[0022] A reinforced sound-insulating mat for the roof of a car with a composite layered structure, the sound-insulating mat is a three-layer composite structure, the upper layer and the lower layer are kraft paper layers coated on the surface, and the grammage is 200g / m 2 , the coating is 20g / m 2 , kraft paper coated with PE film on both sides, the middle layer is 50kg / m 3 High-density polyurethane sound insulation material layer, thickness 8mm. The high-density polyurethane sound-insulating material layer 2 is polyurethane semi-rigid foam, and the weight ratio of polyether and isocyanate is 70:30 after stirring and mixing, then foaming, and then cutting to obtain a high-density sound-insulating material layer with a uniform thickness of 8 mm.

Embodiment 3

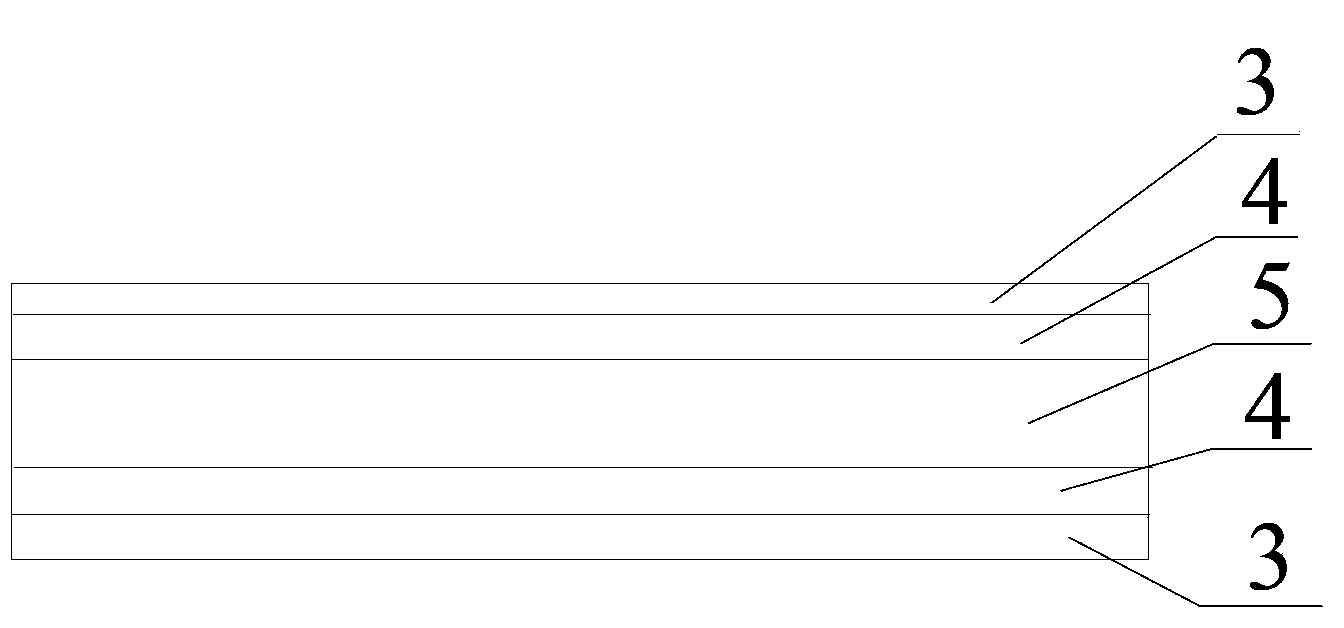

[0024] A kind of composite laminated roof reinforced sound insulation pad for automobiles, its structure is as follows figure 2 As shown, the sound insulation pad is a five-layer composite structure, the upper layer and the lower layer are surface-coated non-woven fabrics 3, and the weight is 200g / m 2 , the coating is 20g / m 2 , coated with PE film on both sides of non-woven fabric, the middle layer is 30kg / m 3 Low-density polyurethane sound insulation material layer 5, 2 layers of 100g / m between non-woven fabric and polyurethane 2 The glass fiber mat layer 4.

[0025] The high-density polyurethane sound insulation material layer is made of polyurethane semi-rigid foam with a density of 30kg / m 3 , The weight ratio of polyether and isocyanate is 50:25, stirring and mixing, foaming, and then cutting to obtain a low-density sound-insulating material layer with a uniform thickness of 6 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com