Method for matching and optimizing parameters of mixed power locomotive with fuel cell and super capacitor

A supercapacitor and fuel cell technology, applied in electric vehicles, electric traction, control drive, etc., can solve problems such as the inability to ensure the best matching of energy flow in the vehicle and the inability to obtain the best fuel economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific implementation process of the present invention is described in detail as follows.

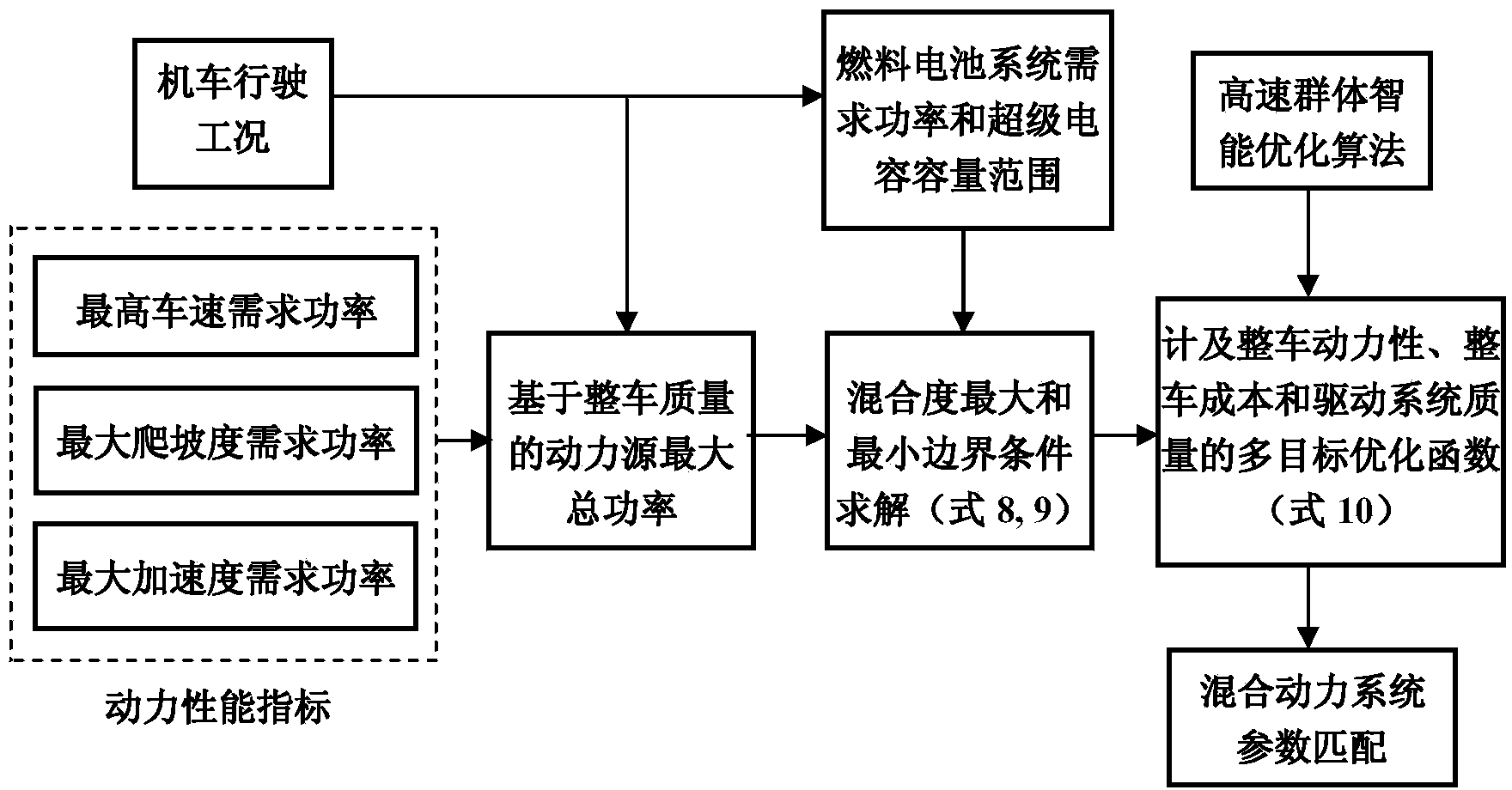

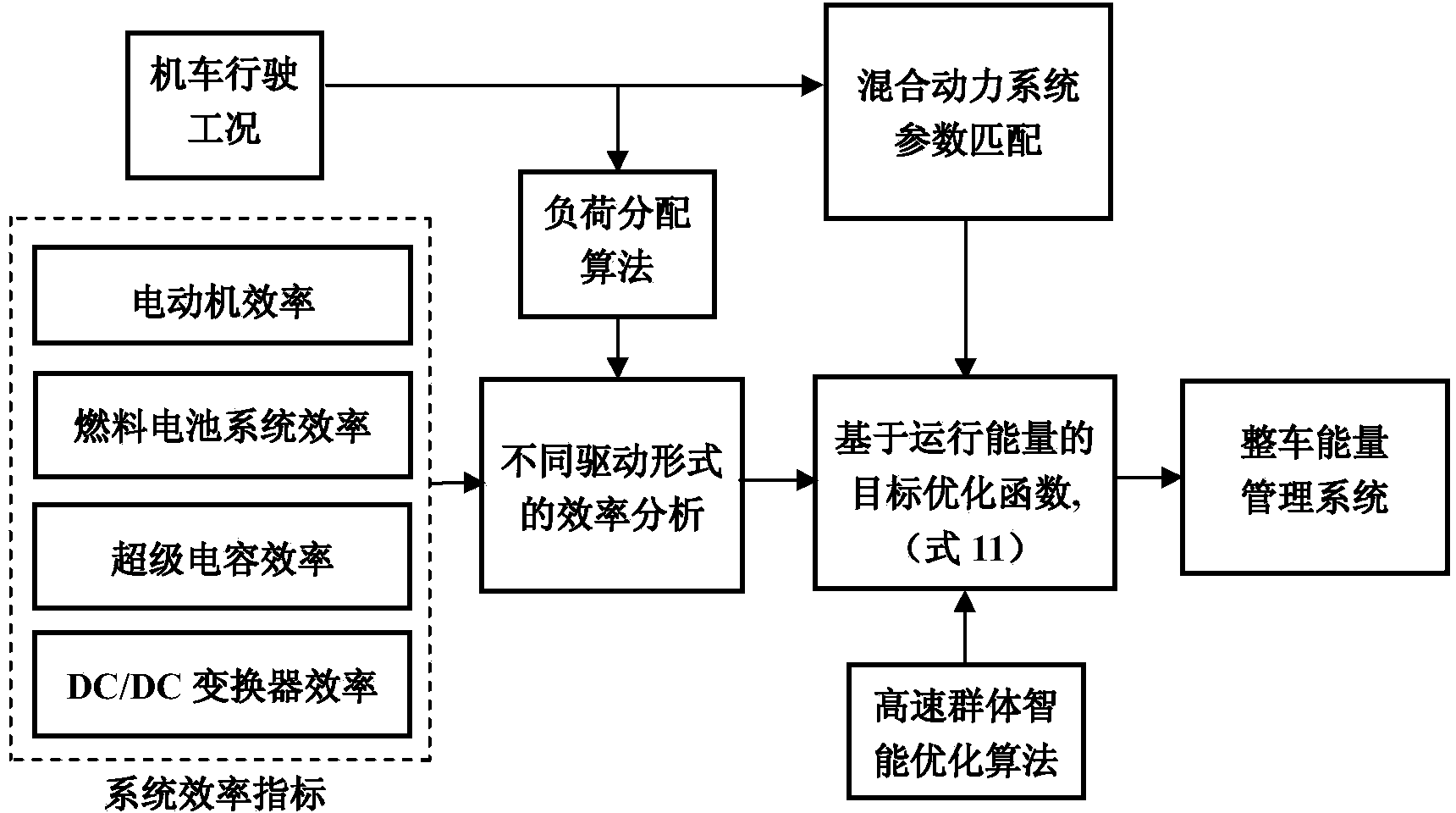

[0038] 1. Parameter matching optimization method for fuel cell / supercapacitor hybrid locomotive

[0039] First, under a certain working condition, according to the maximum speed demand power P v , the maximum climbing gradient required power P i , maximum acceleration demand power P a Determine the maximum total power P of the power source max ,Right now

[0040] P v = c 1 M+c 2 (1)

[0041] P i = c 3 M+c 4 (2)

[0042] P a = c 5 M+c 6 (3)

[0043] P max =max{P v ,P i ,P a} (4)

[0044] In the formula, P v ,P i ,P a Expressed as a form related to the vehicle mass M, c 1 -c 6 is the transmission coefficient, which is determined by the dynamic performance index of the locomotive and the relevant parameters of the car body. In the design, the vehicle mass M is regarded as composed of four parts: drive system, chassis non-drive train part, bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com