A treatment process and device for aluminum-plastic composite film for anti-hydrofluoric acid corrosion

A technology of aluminum-plastic composite film and processing device, which is applied in the field of anti-corrosion treatment of aluminum-plastic composite film, can solve the problems of packaging materials such as loss of protection, barrier, anti-hydrofluoric acid performance not meeting requirements, high production cost, etc. Strong, easy to control, pollution-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

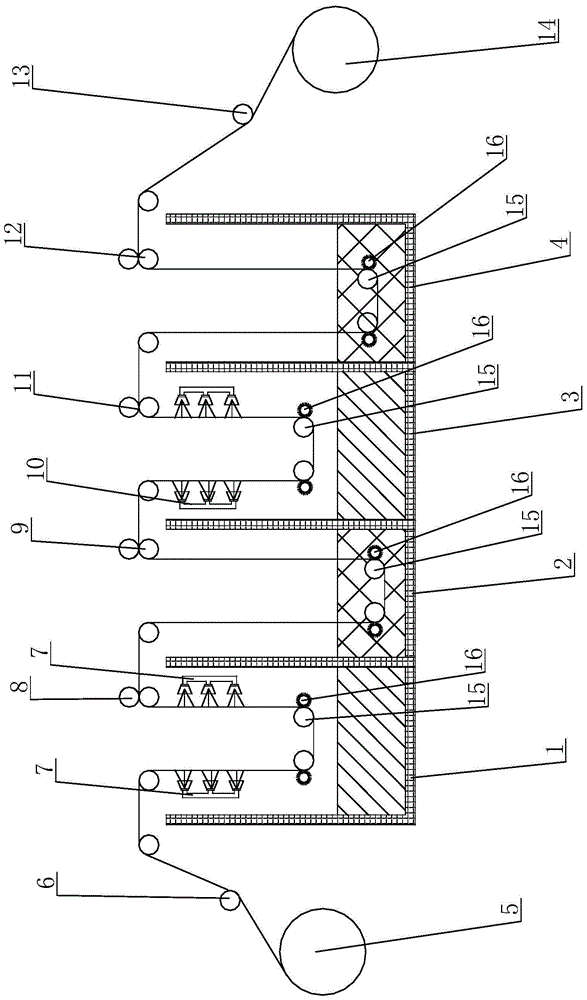

[0043] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0044] see figure 1 as shown, figure 1 It is a schematic structural view of the hydrofluoric acid corrosion-resistant aluminum-plastic composite film treatment device provided in Embodiment 1 of the present invention.

[0045] In this embodiment, a hydrofluoric acid corrosion-resistant aluminum-plastic composite film processing device includes a discharging mechanism and a receiving mechanism, and a hot lye tank 1 and a hot water tank are sequentially arranged between the discharging mechanism and the receiving mechanism. 2. The hydrofluoric acid tank 3 and the cold water tank 4, the hot lye tank 1, the hot water tank 2, the hydrofluoric acid tank 3 and the cold water tank 4 are all made of polytetrafluoroethylene plates, and the discharging mechanism includes a Feeding roller 5 and feeding guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com