Automated production line static elimination and dust removal system

An automatic production line and static elimination technology, applied in the direction of static electricity, electrical components, chemical instruments and methods, etc., can solve problems such as static electricity accumulation, board card quality degradation, space pollution, etc., and achieve the effect of avoiding the blowing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

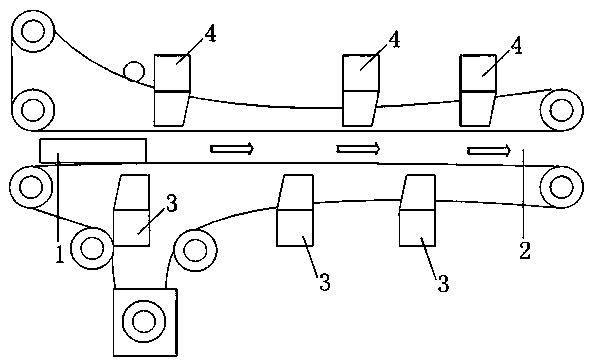

[0024] Such as figure 1 , in this embodiment, the automatic production line static elimination and dust removal system is arranged on the production line 2 to remove dust and welding slag on the workpiece 1. The workpiece 1 can be electronic components such as circuit boards.

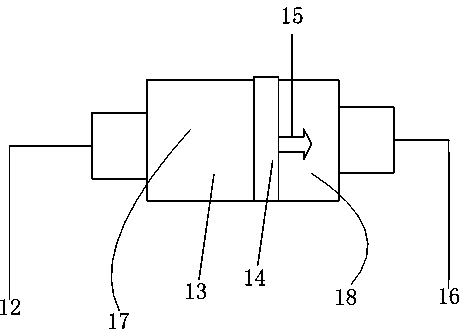

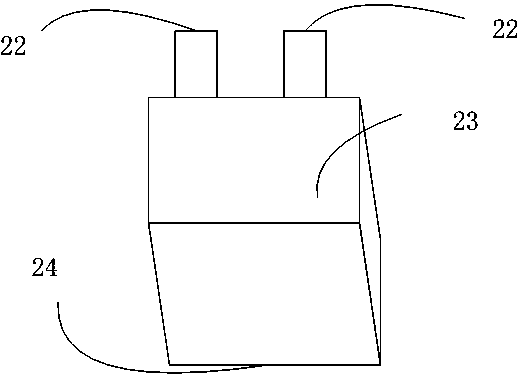

[0025] The automatic production line static elimination and dust removal system includes at least one pair of paired dust removal device 3 and vacuum absorption device 4. The dust removal device 3 is arranged on one side of the production line 2 in the transverse direction, and has an air outlet 24, an air outlet 24 blows air to the other side of the production line 2 to separate the dust residue from the workpiece 1 on the production line 2; wind to collect dust. In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com