Gas barrier film, method for producing same, gas barrier film laminate, member for electronic devices, and electronic device

A technology for electronic devices and gas-barrier films, applied in electrical components, lighting devices, electronic equipment, etc., to achieve low birefringence, high gas-barrier properties, and excellent gas-barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

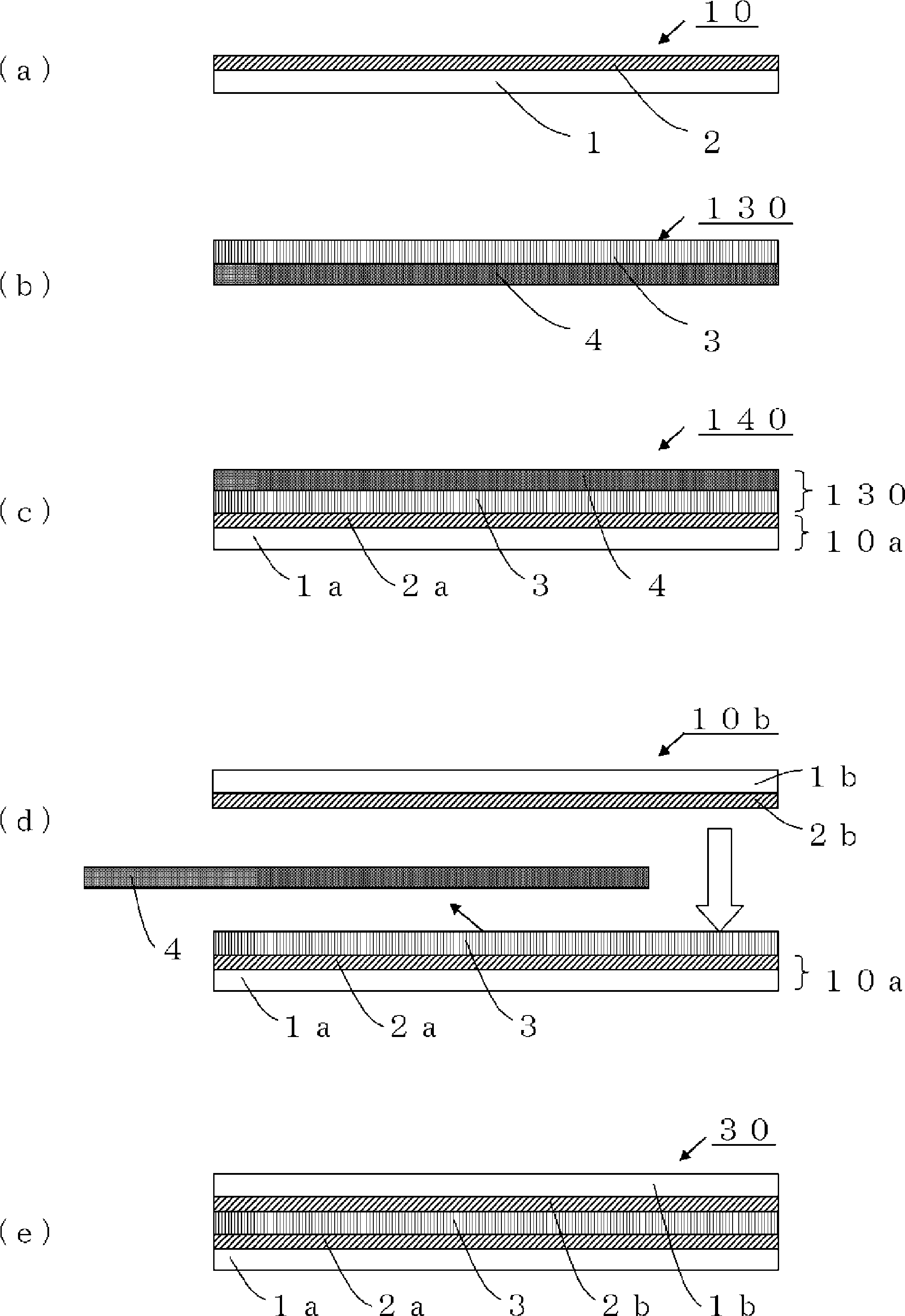

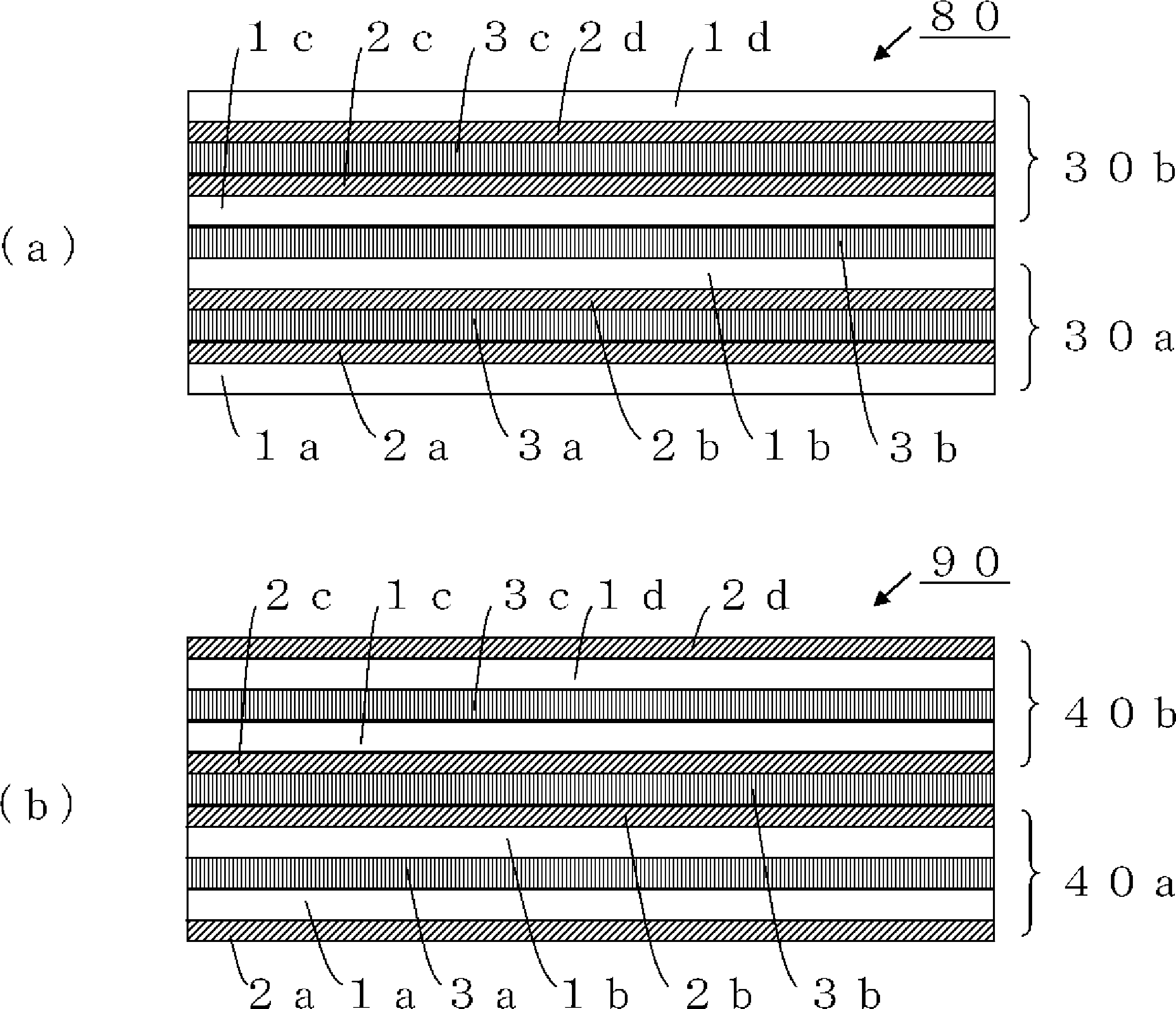

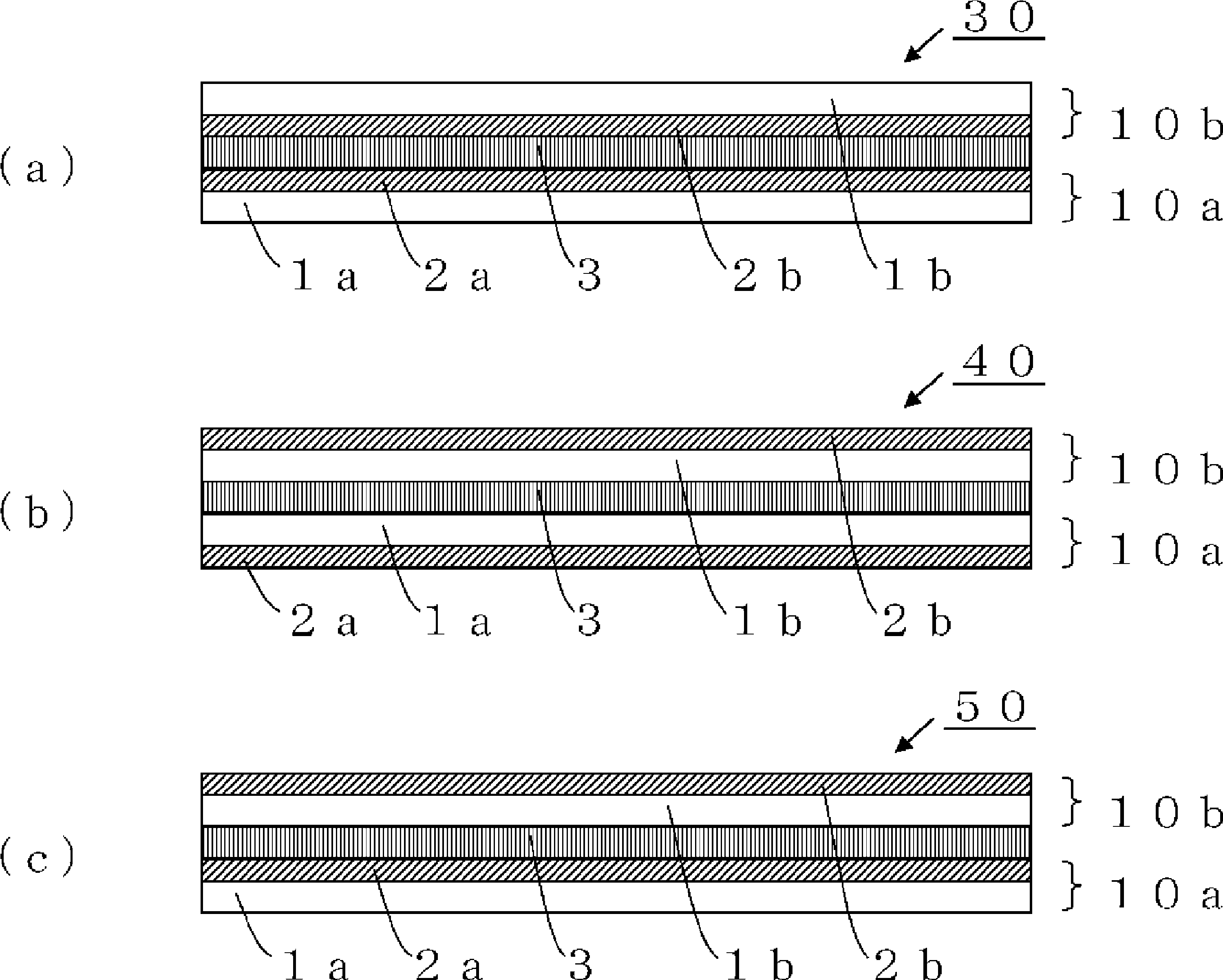

Method used

Image

Examples

Embodiment

[0368] Hereinafter, the present invention will be described in more detail with reference to examples. However, the present invention is not limited by the following examples.

[0369] Hereinafter, unless otherwise specified, "part" means "part by mass".

[0370] [Preparation of curable resin composition]

manufacture example 1)

[0371] (Manufacturing example 1) Preparation of curable resin composition 1

[0372] As the thermoplastic resin (A), 60 parts of pellets of polysulfone resin (PSF) (manufactured by BASF, ULTRASON S3010, Tg=180° C.) were dissolved in methylene chloride to prepare a 15% by mass solution of PSF. Next, 40 parts of tricyclodecane dimethanol diacrylate (manufactured by Shin-Nakamura Chemical Industry Co., Ltd., ADCP) as a curable monomer (B) and bis(2,4, One part of 6-trimethylbenzoyl)phenylphosphine oxide (Irgacure 819, manufactured by BASF) was mixed to prepare a curable resin composition 1 .

manufacture example 2~5)

[0373] (Production Examples 2 to 5) Preparation of Curable Resin Compositions 2 to 5

[0374] Curable resin compositions 2-5 were prepared by the method similar to the preparation method of curable resin composition 1 except having changed to the compounding ratio of Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com