Mixing device for reducing agent preparation

A technology of mixing device and additives, applied in mixers, exhaust devices, mixing methods, etc., can solve problems such as increasing exhaust gas back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

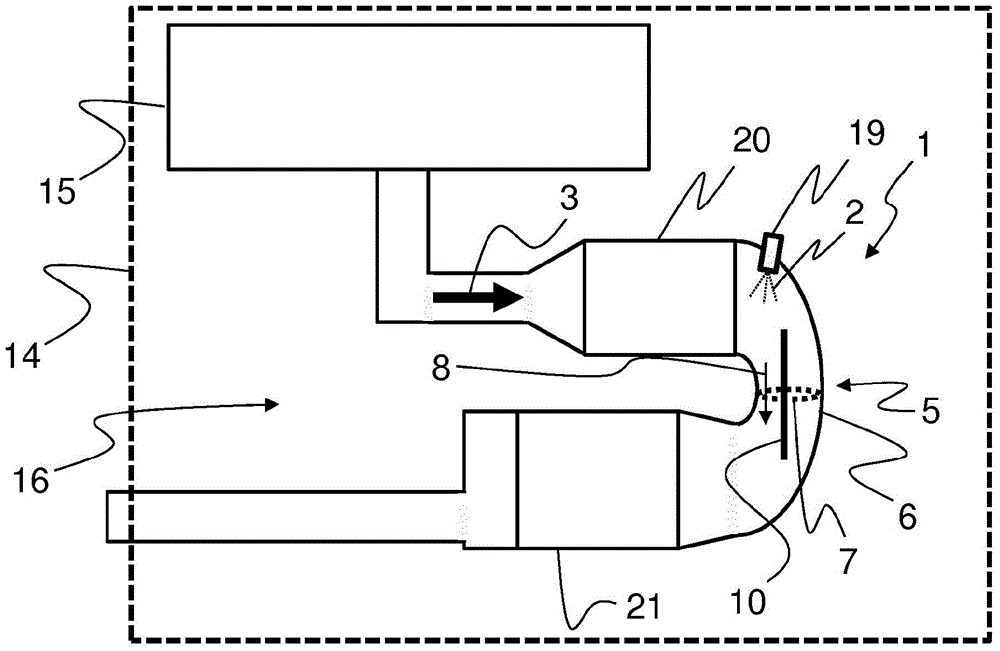

[0031] figure 1 A motor vehicle 14 with an internal combustion engine 15 and an exhaust gas system 16 is shown. The internal combustion engine 15 is preferably a diesel engine or a lean-burn (with excess air) gasoline engine. In this example, the exhaust gas flow 3 in the exhaust system 16 first flows (overflows) through the first exhaust gas purification element 20 and, after flowing through the mixing section 5 , through the second exhaust gas purification element 21 . In this example, an oil injector 19 is connected directly to the connection to the first exhaust gas purification element 20 , which injects the additive 2 into the exhaust gas flow 3 . Arranged in the adjacent mixing device 1 are plates 10 which are oriented in the main flow direction 8 of the exhaust gas flow 3 . This device is a preferred device established in the prior art, but said device does not constitute a restriction of the concept of the invention. The exhaust gas line 6 in the region of the mixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com