Automatic production line for dynamic soft package lithium battery encapsulation

An automated production line and soft-pack lithium battery technology, which is applied in battery assembly machines, secondary battery manufacturing, non-aqueous electrolyte batteries, etc., can solve problems such as high labor costs, scattered production equipment layout, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

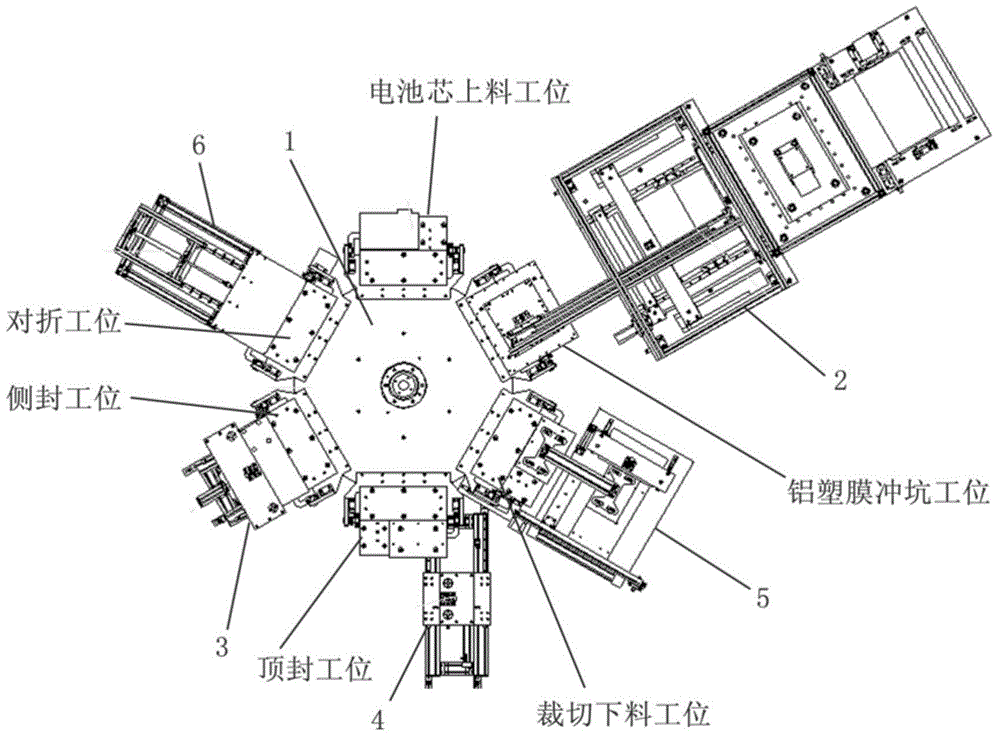

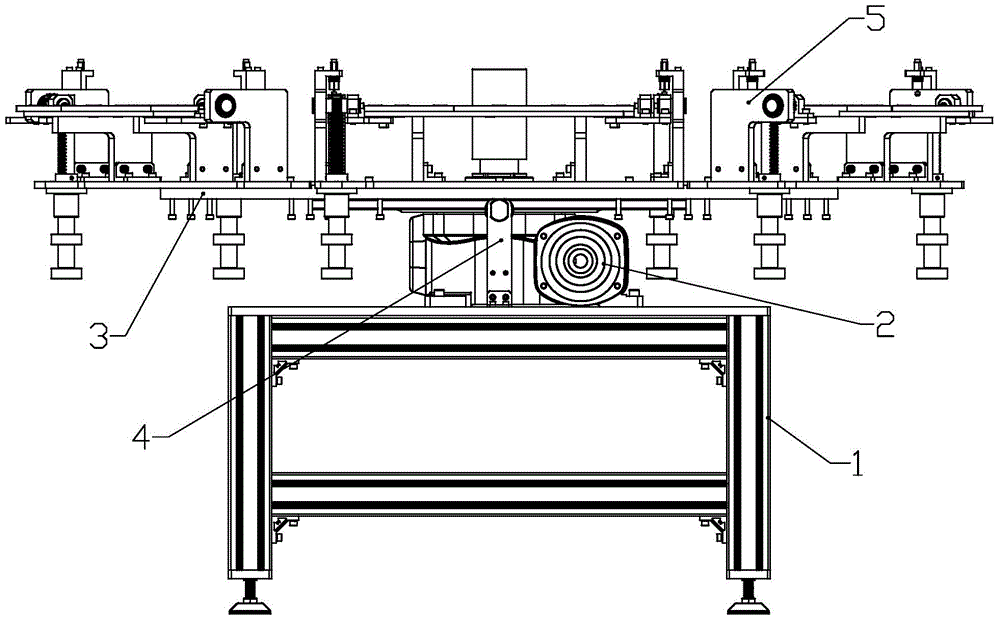

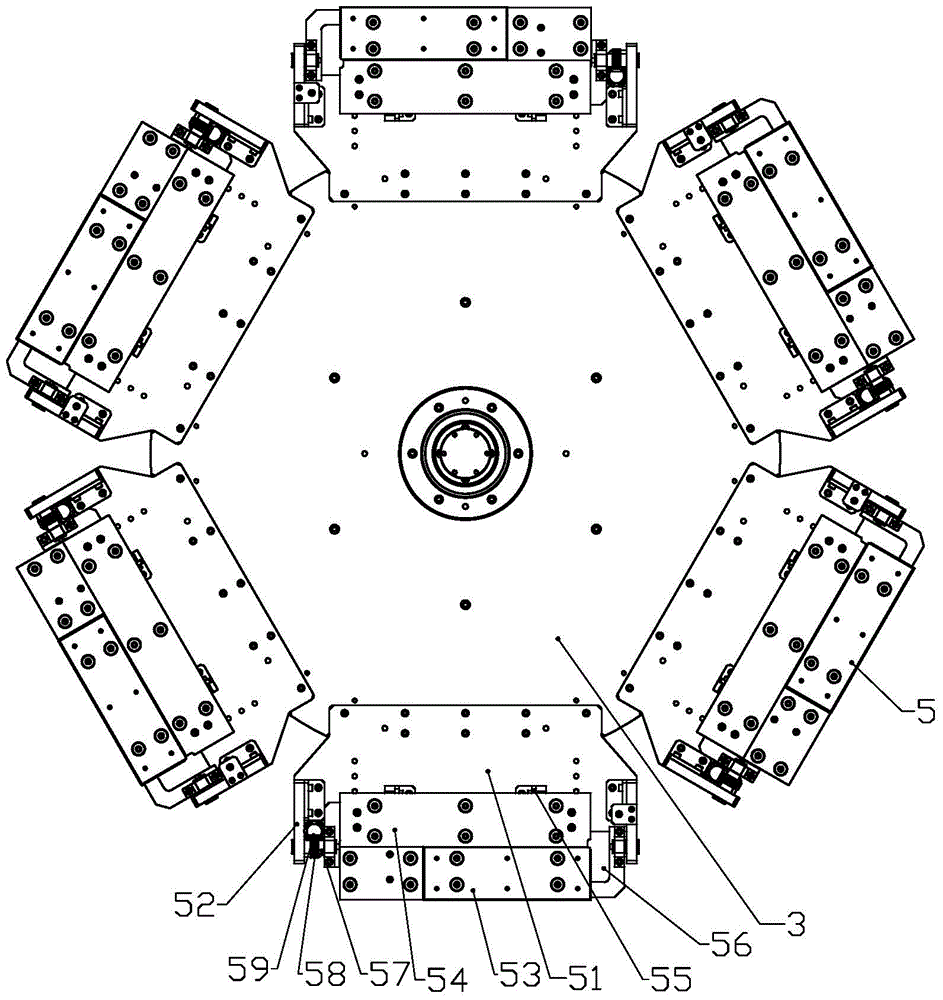

[0072] Refer to the attached figure 1 To attach Figure 20 A power soft-pack lithium battery packaging automatic production line of the present invention will be described in detail below.

[0073] An automatic production line for encapsulating power soft-pack lithium batteries according to the present invention, the structure of which includes an automatic circulation device 1 for fixtures. The automatic circulation device for fixtures 1 is sequentially provided with an aluminum-plastic film punching station and a battery core loading station in the circumferential direction. , half-folding station, side sealing station, top-sealing station and cutting and blanking station, the aluminum-plastic film punching station is provided with an aluminum-plastic film automatic punching machine 2, and the half-folding station is provided with an aluminum Plastic film folding device 6, aluminum-plastic film side sealing device 3 is installed at the side sealing station, aluminum-plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com