A microbial fuel cell for in situ remediation of nitrate pollution in groundwater

A fuel cell and groundwater technology, applied in the field of groundwater nitrate pollution control, can solve problems such as MFC technical obstacles, and achieve the effects of overcoming the difficulty of implementation, facilitating long-term use, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

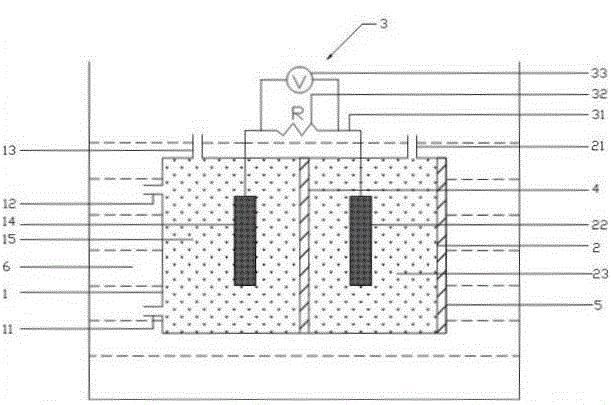

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] The invention utilizes a biocathode type microbial fuel cell to restore groundwater nitrate pollution in situ. The anion exchange membrane is used as the channel for nitrate in the groundwater to enter the MFC cathode chamber, and at the same time prevents the microorganisms in the MFC from entering the groundwater environment, which can effectively avoid the secondary pollution of the groundwater by microorganisms and organic matter; the denitrifying bacteria in the cathode chamber are used as catalysts to enter The nitrate in the groundwater in the cathode chamber accepts the electrons on the cathode and reduces to nitrogen to be removed. The specific structure of the microbial fuel cell is as follows:

[0031] refer to figure 1 As shown, a biocathode microbial fuel cell for in-situ remediation of groundwater nitrate pollut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com