Two-stage acceleration permanent magnetic mechanism used for high-voltage large-open-distance vacuum circuit breaker

A vacuum circuit breaker and permanent magnet mechanism technology, which is applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problems of limiting the application of permanent magnet mechanisms, large air gap reluctance, control, etc., and achieve the reduction of work Effects of air gap, mass reduction, and eddy current loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment mode, the patent of the present invention is described in further detail:

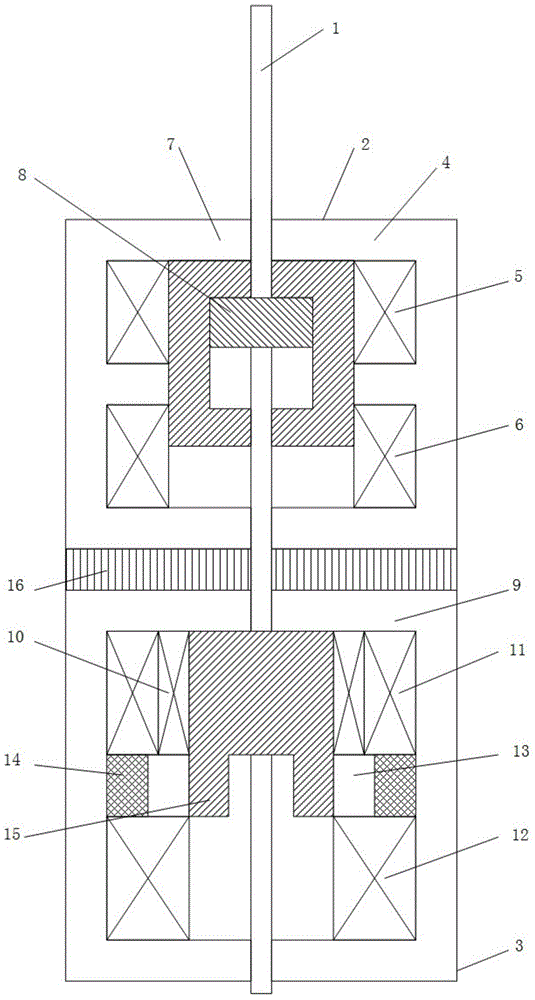

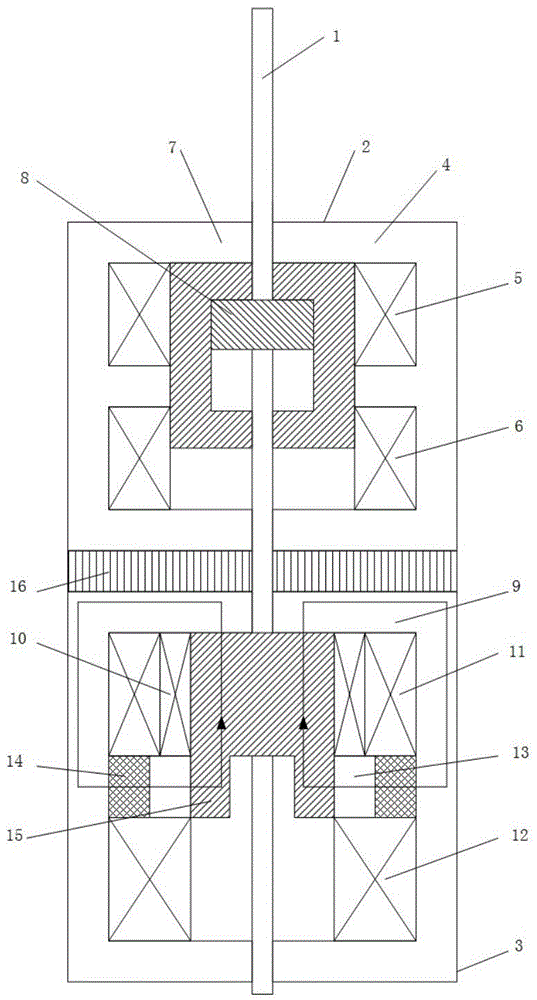

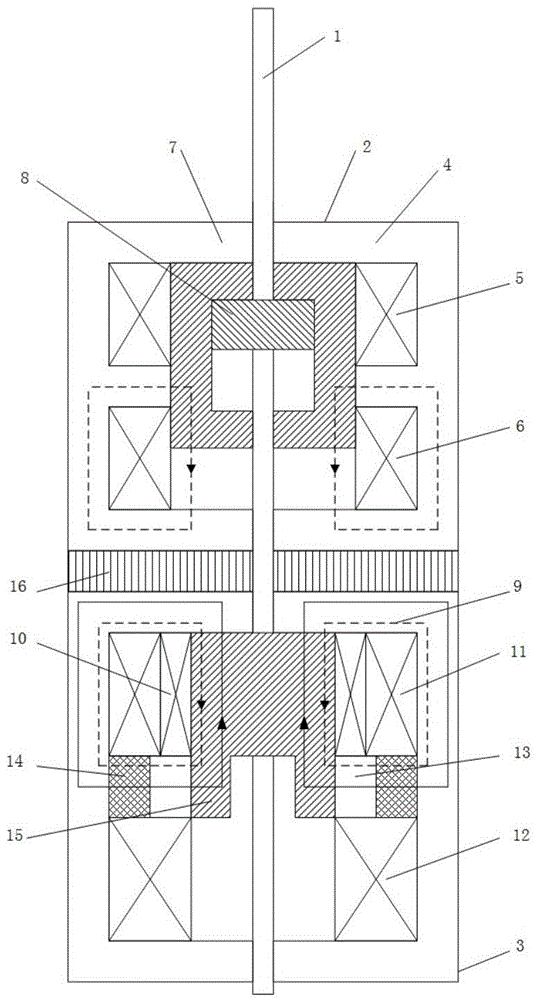

[0027] The invention discloses a permanent magnet mechanism for a high-voltage large-distance circuit breaker provided with an auxiliary starting mechanism, which includes an auxiliary starting mechanism 2, a main body operating mechanism 3 and a guide rod 1 connected with a moving contact of the circuit breaker.

[0028] The auxiliary starting mechanism 2 includes: a first static iron core 4, an auxiliary moving iron core 7 located inside the first static iron core 4, a starting closing coil 5 located above the interior of the first static iron core 4 and surrounding the upper outer surface of the auxiliary moving iron core 7, The starting opening coil 6 located above the interior of the first static iron core 4 and surrounding the lower outer surface of the auxiliary moving iron core 7 , and the push plate 8 located inside the auxili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com