Construction Laser System

A technology of laser system and building, applied in the field of building laser system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

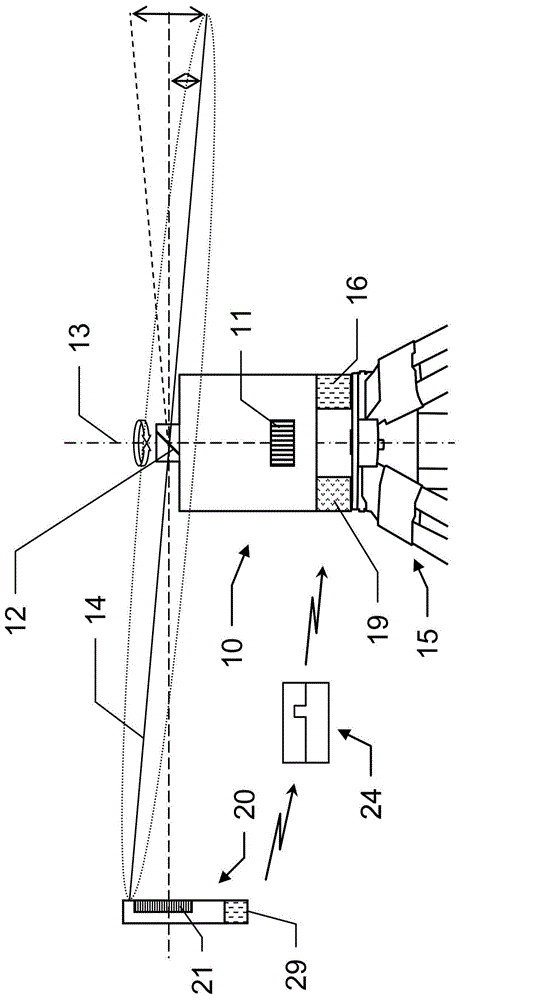

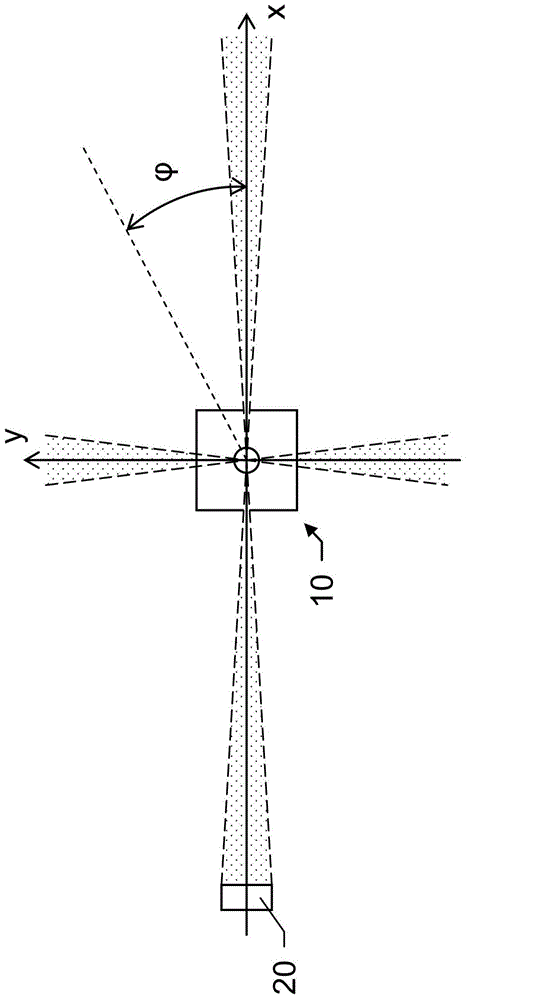

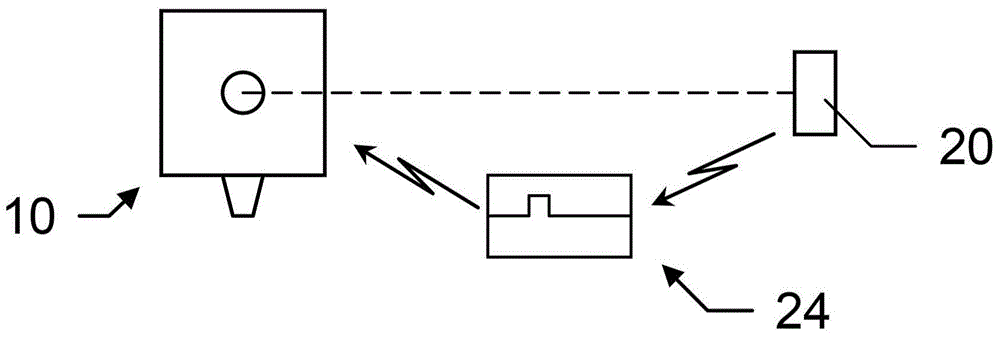

[0130] figure 1 An exemplary embodiment of a construction laser system according to the invention is shown, comprising a rotating laser 10 with a laser unit 11 and a rotatable deflection device 12 for emitting a rotating laser beam 14, wherein the rotating laser a beam-defining reference area; and a laser receiver 20, which includes a laser beam detector 21 extending at least on a one-dimensional area on the laser receiver and designed to respond to the laser beam on the laser beam detector The irradiated position generates an output signal 24 . Furthermore, an evaluation and control unit 16 is provided.

[0131] In this case, the rotating laser 10 has a beam leveling function to be recalibrated, in particular a beam self-leveling function to be recalibrated. To provide this functionality, the rotating laser in this case has

[0132] ●Level sensor,

[0133] a mechanism for at least slightly inclining the axis of rotation with respect to the support of the rotating laser (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com