Method of synthesizing acrylamide by using acrylonitrile hydratase

A technology for acrylonitrile hydration and acrylamide, applied in the direction of microorganism-based methods, biochemical equipment and methods, and specific-purpose bioreactors/fermenters, can solve the problems of heat transfer in hydration reactions, enzyme inactivation, etc., and achieve Reduce the inhibitory effect, increase the specific surface area, and avoid the effect of excessive local concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

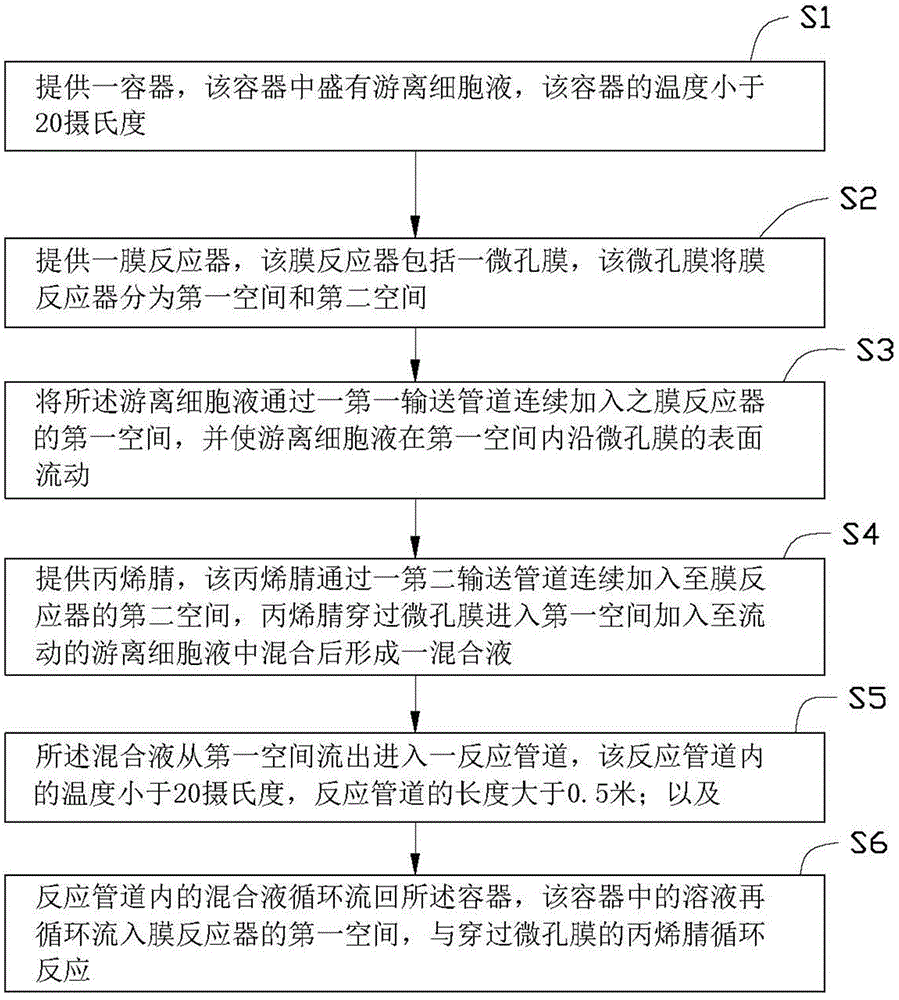

[0027] In the preparation method of acrylamide provided by the present invention, acrylonitrile undergoes a hydration reaction under the catalysis of acrylonitrile hydratase in free cell fluid:

[0028]

[0029] In the above reaction process, because acrylonitrile and the acrylamide produced will inhibit the enzyme activity of acrylonitrile hydratase, experiments have shown that acrylonitrile will inhibit the enzyme activity when the concentration reaches 0.4mol / L. The cell culture medium must be added slowly. Therefore, in the traditional preparation method of acrylamide, the whole reaction takes a long time, and in order to ensure sufficient mixing, strong stirring is often used to increase energy consumption to a large extent; on the other hand, since acrylamide reaches 250g / L also has a more obvious inhibitory effect on the enzyme activity, so the traditional industrial stirred tank reactor can only obtain acrylamide products with a lower concentration in a longer reac...

Embodiment 1

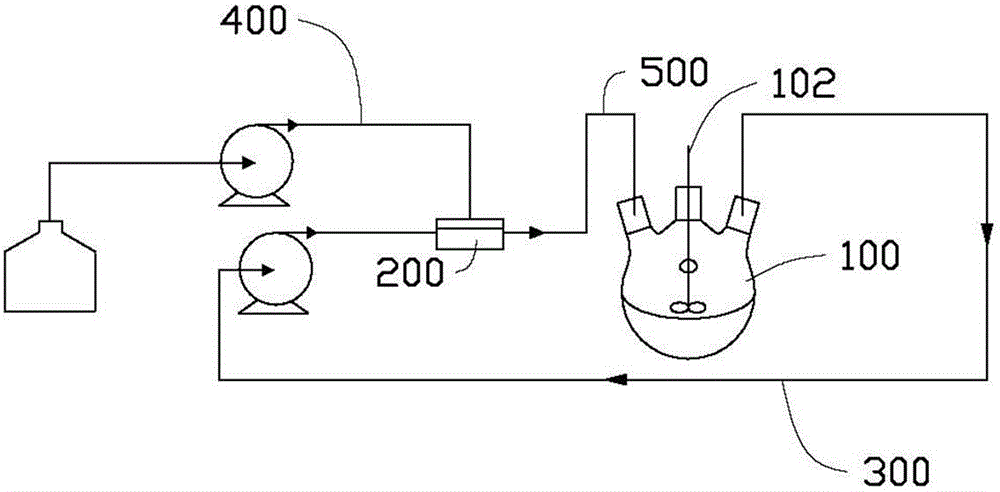

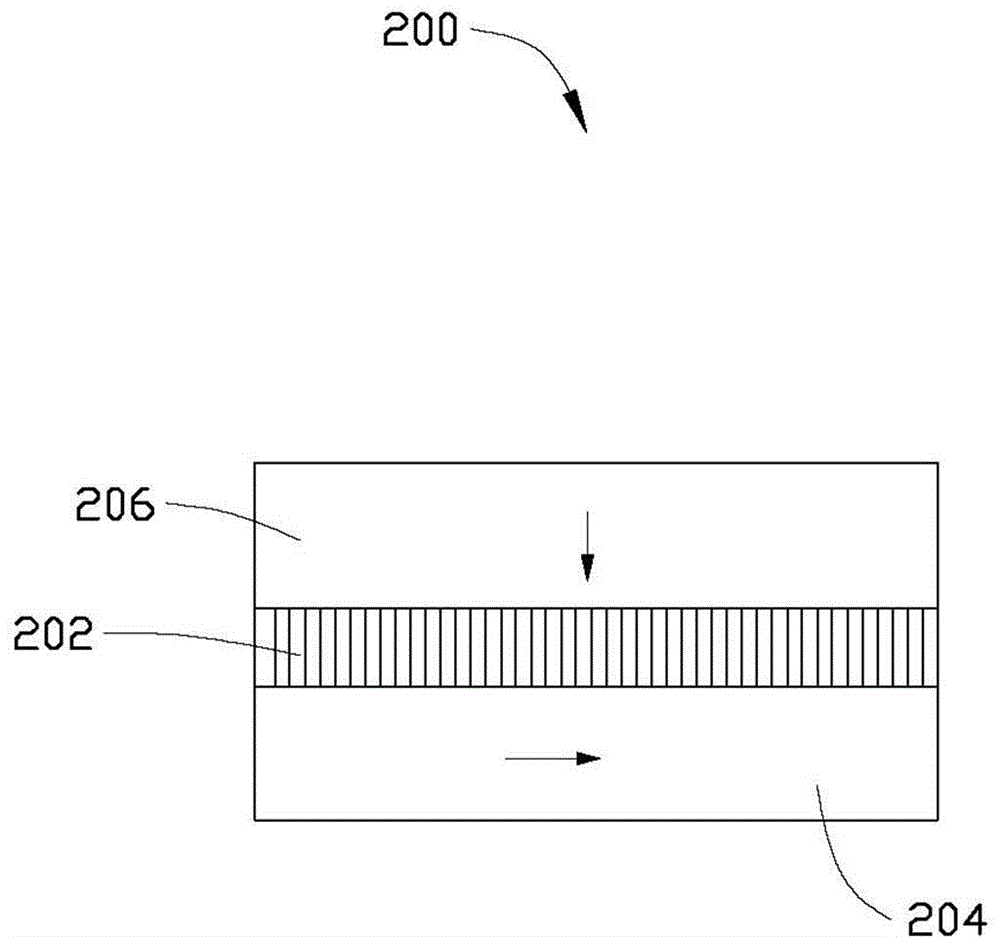

[0034] The dispersed phase used is the oil phase, that is, pure acrylonitrile. The initial continuous phase is TH-3 type Rhodococcus free cell fluid. Take 80mL of free cell solution with an enzyme activity of 2000U, put it into a three-neck flask and stir. The three-neck flask was placed in an ice-water bath to ensure that the temperature of the entire reaction system was not higher than 5°C. A membrane dispersion reactor is used to mix and react acrylonitrile and free cell liquid, the continuous phase is continuously circulated and the dispersed phase is sheared to form monodisperse acrylonitrile droplets, and the catalytic reaction is carried out. After the mixed acrylonitrile and free cell liquid are mixed, the reaction continues through a 1-meter-long coil, and the temperature in the coil is guaranteed not to be higher than 5°C. The reacted mixed solution flows into a three-necked flask to continue to catalyze the acrylonitrile and circulate continuously. 2 mL of the mix...

Embodiment 2

[0036] The dispersed phase used is the oil phase, that is, pure acrylonitrile. The initial continuous phase is TH-3 type Rhodococcus free cell fluid. Take 80mL of free cell solution with an enzyme activity of 2000U, put it into a three-neck flask and stir. The three-neck flask was placed in an ice-water bath to ensure that the temperature of the entire reaction system was not higher than 5°C. A membrane dispersion reactor is used to mix and react acrylonitrile and free cell liquid, the continuous phase is continuously circulated and the dispersed phase is sheared to form monodisperse acrylonitrile droplets, and the catalytic reaction is carried out. After the mixed acrylonitrile and free cell liquid are mixed, the reaction continues through a 1-meter-long coil, and the temperature in the coil is guaranteed not to be higher than 5 oC. The reacted mixed solution flows into a three-necked flask to continue to catalyze acrylonitrile and circulate continuously. 2 mL of the mixtur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com