Anti-rust sealing agent and preparation method and use thereof, and hot-dip plated metal material

A hot-dip metal and sealing agent technology, which is applied in the field of anti-rust sealant and hot-dip metal materials, can solve the problems of poor corrosion resistance of the protective film, and achieve the effect of excellent storage resistance and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

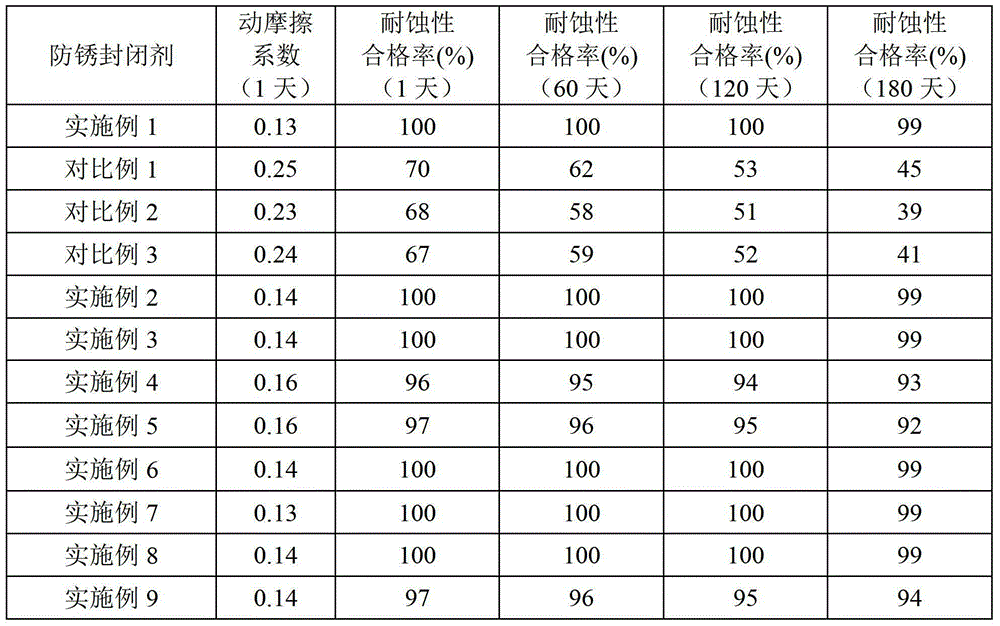

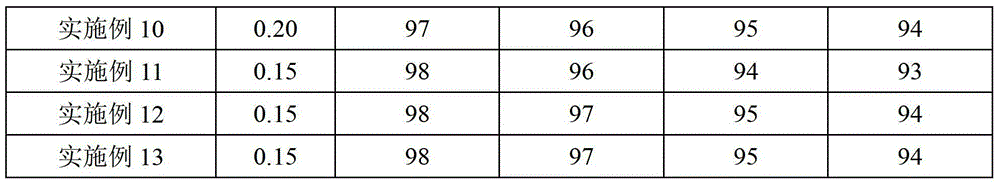

Examples

preparation example Construction

[0013] The invention provides a preparation method of an antirust sealant, which comprises mixing water, a silane coupling agent, a water-soluble silicate, an accelerator, a silicon oxide filler and a water-soluble film-forming resin in sequence; the silane The coupling agent is Cl(CH 2 ) 3 Si(OCH 3 ) 3 , Cl(CH 2 ) 3 Si(OC 2 h 5 ) 3 , Cl(CH 2 ) 3 SiCH 3 (OCH 3 ) 2 and Cl(CH 2 ) 3 SiCH 3 (OC 2 h 5 ) 2 At least one of them; the accelerator is thiourea and / or urea.

[0014] Wherein, in detail, the method includes: (1) uniformly mixing water and the silane coupling agent to obtain a uniform liquid A; (2) uniformly mixing the uniform liquid A and a water-soluble silicate to obtain a uniform liquid B; (3) uniformly mix the uniform liquid B and accelerator to obtain uniform liquid C; (4) uniformly mix the uniform liquid C and silicon oxide filler to obtain uniform liquid D; (5) uniformly Liquid D is uniformly mixed with water-soluble film-forming resin to obtain u...

Embodiment 1

[0051] With 28 parts by weight of water and 1.6 parts by weight of silane coupling agent (Cl(CH 2 ) 3 Si(OCH 3 ) 3 , purchased from Hubei Debang Chemical New Material Co., Ltd., brand DB-231) and mixed until uniform at a stirring speed of 1500 rpm to obtain a uniform liquid A.

[0052] Mix all the uniform liquid A and 1 part by weight of water-soluble silicate (sodium metasilicate pentahydrate, purchased from Qingdao Darun Chemical Co., Ltd.) at a stirring speed of 1500 rpm until uniform to obtain uniform liquid B .

[0053] All of the homogeneous liquid B and 0.6 parts by weight of accelerator (thiourea) were mixed until uniform at a stirring speed of 1500 rpm to obtain a homogeneous liquid C.

[0054] All the homogeneous liquid C and 0.72 parts by weight of silica filler (nano silica sol, purchased from Shandong Baite New Material Co., Ltd., the brand is SS-30, and the weight is calculated as silica) at 1500 rpm Mix until homogeneous at stirring speed to obtain homogene...

Embodiment 2

[0063] With 25 parts by weight of water and 1.4 parts by weight of silane coupling agent (Cl(CH 2 ) 3 Si(OCH 3 ) 3 , purchased from Hubei Debang Chemical New Material Co., Ltd., brand DB-231) and mixed until uniform at a stirring speed of 1500 rpm to obtain a uniform liquid A.

[0064] All of the uniform liquid A and 1 part by weight of water-soluble silicate (potassium silicate, purchased from Baoding Runfeng Industrial Co., Ltd.) were mixed until uniform at a stirring speed of 1500 rpm to obtain a uniform liquid B.

[0065] All of the homogeneous liquid B and 0.5 parts by weight of accelerator (an equal weight mixture of thiourea and urea) were mixed until uniform at a stirring speed of 1500 rpm to obtain a homogeneous liquid C.

[0066] Mix all the homogeneous liquid C and 0.6 parts by weight of silica filler (nano silica sol, purchased from ADEKA Co., Ltd., the brand is AT-30, and the weight is calculated as silica) at a stirring speed of 1500 rpm until uniform, to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com