Metal protective water-based paint, preparation method and application thereof, and hot-dipped metal material

A metal protection and hot-dip metal technology, which is applied in the direction of anti-corrosion coatings, metal layered products, chemical instruments and methods, etc., can solve the problems of poor corrosion resistance of the protective film, and achieve excellent storage resistance and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

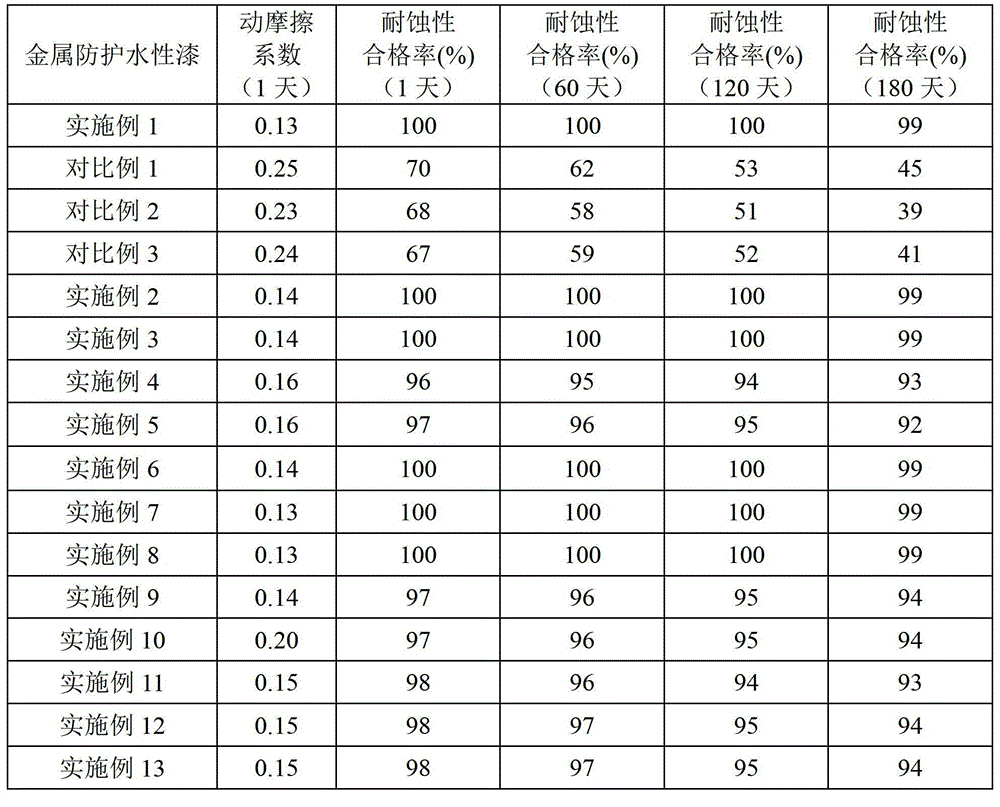

Examples

preparation example Construction

[0013] The invention provides a kind of preparation method of water-based paint for metal protection, the method comprises water, silane coupling agent, water-soluble silicate, accelerator, silicon oxide filler and water-soluble film-forming resin are mixed successively; The coupling agent is HS(CH 2 ) 3 Si(OCH 3 ) 3 、HS(CH 2 ) 3 Si(OC 2 h 5 ) 3 、HS(CH 2 ) 3 SiCH 3 (OCH 3 ) 2 and HS(CH 2 ) 3 SiCH 3 (OC 2 h 5 ) 2 At least one of them; the accelerator is thiourea and / or urea.

[0014] Wherein, in detail, the method includes: (1) uniformly mixing water and the silane coupling agent to obtain a uniform liquid A; (2) uniformly mixing the uniform liquid A and a water-soluble silicate to obtain a uniform liquid B; (3) uniformly mix the uniform liquid B and accelerator to obtain uniform liquid C; (4) uniformly mix the uniform liquid C and silicon oxide filler to obtain uniform liquid D; (5) uniformly Liquid D is uniformly mixed with water-soluble film-forming resin...

Embodiment 1

[0051] With the water of 28 parts by weight and the silane coupling agent (HS(CH) of 1.6 parts by weight 2 ) 3 Si(OCH 3 ) 3 , purchased from Hubei Debang Chemical New Material Co., Ltd., brand DB-590) and mixed until uniform at a stirring speed of 1500 rpm to obtain a uniform liquid A.

[0052] Mix all the uniform liquid A and 1 part by weight of water-soluble silicate (sodium metasilicate pentahydrate, purchased from Qingdao Darun Chemical Co., Ltd.) at a stirring speed of 1500 rpm until uniform to obtain uniform liquid B .

[0053] All of the homogeneous liquid B and 0.6 parts by weight of accelerator (thiourea) were mixed until uniform at a stirring speed of 1500 rpm to obtain a homogeneous liquid C.

[0054] All the homogeneous liquid C and 0.72 parts by weight of silica filler (nano silica sol, purchased from Shandong Baite New Material Co., Ltd., the brand is SS-30, and the weight is calculated as silica) at 1500 rpm Mix until homogeneous at stirring speed to obtain...

Embodiment 2

[0063] With the water of 25 parts by weight and the silane coupling agent (HS(CH) of 1.4 parts by weight 2 ) 3 Si(OC 2 h 5 ) 3 , purchased from Hubei Debang Chemical New Material Co., Ltd., brand DB-580) and mixed until uniform at a stirring speed of 1500 rpm to obtain a uniform liquid A.

[0064] All of the uniform liquid A and 1 part by weight of water-soluble silicate (potassium silicate, purchased from Baoding Runfeng Industrial Co., Ltd.) were mixed until uniform at a stirring speed of 1500 rpm to obtain a uniform liquid B.

[0065] All of the homogeneous liquid B and 0.5 parts by weight of accelerator (an equal weight mixture of thiourea and urea) were mixed until uniform at a stirring speed of 1500 rpm to obtain a homogeneous liquid C.

[0066] Mix all the homogeneous liquid C and 0.6 parts by weight of silica filler (nano silica sol, purchased from ADEKA Co., Ltd., the brand is AT-30, and the weight is calculated as silica) at a stirring speed of 1500 rpm until un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com