Downwards transportation belt machine anti-sliding damping system for coal mine

A technology of damping system and belt conveyor, which is applied in the direction of conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems of belt conveyor belt sprinkling charcoal, burying the head of the machine, blocking the roadway, and belt conveyor "flying car", etc. The effect of fast and reliable sliding, small belt wear and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

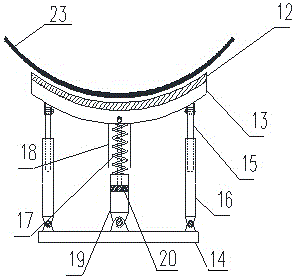

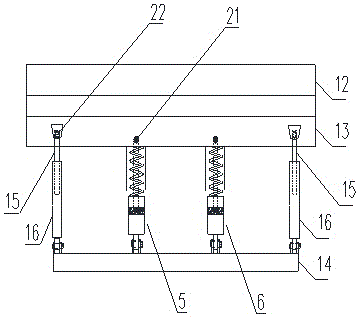

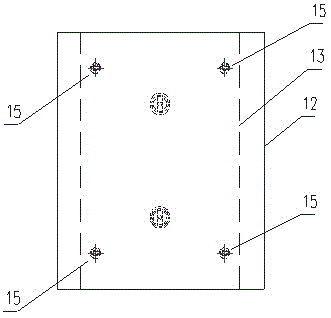

Embodiment 1

[0019] Embodiment 1: The anti-skid damping system includes a hydraulic control device, an electric control device and an actuator; the hydraulic control device includes: a hydraulic station 1, an oil inlet hose 2, an oil return hose 3, a two-way lock 4, a first pressing Oil cylinder 5, second compression cylinder 6, solenoid valve 7 and oil overflow tank 8; hydraulic station 1 is connected with two-way lock 4 through liquid inlet hose 2 and oil return hose 3, and two-way lock 4 is connected through oil inlet hose 2 and oil return hose 3. It is connected with the first compression cylinder 5 and the second compression cylinder 6. The oil inlet hose 2 is connected with the solenoid valve 7 between the two-way lock 4 and the first compression cylinder 5 and the second compression cylinder 6. The solenoid valve The oil return port of 7 is connected with overflow tank 8. The hydraulic station 1 includes an oil pump.

[0020] The two-way lock 4 includes two one-way valves, which ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com