Preparation method of sulfur doped graphite-phase carbon nitride visible-light catalyst and product obtained by using method

A graphitic carbon nitride, visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of limited improvement in photocatalytic activity for degrading pollutants, and achieve excellent photocatalysis. Performance and stability, environmental friendliness, short cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

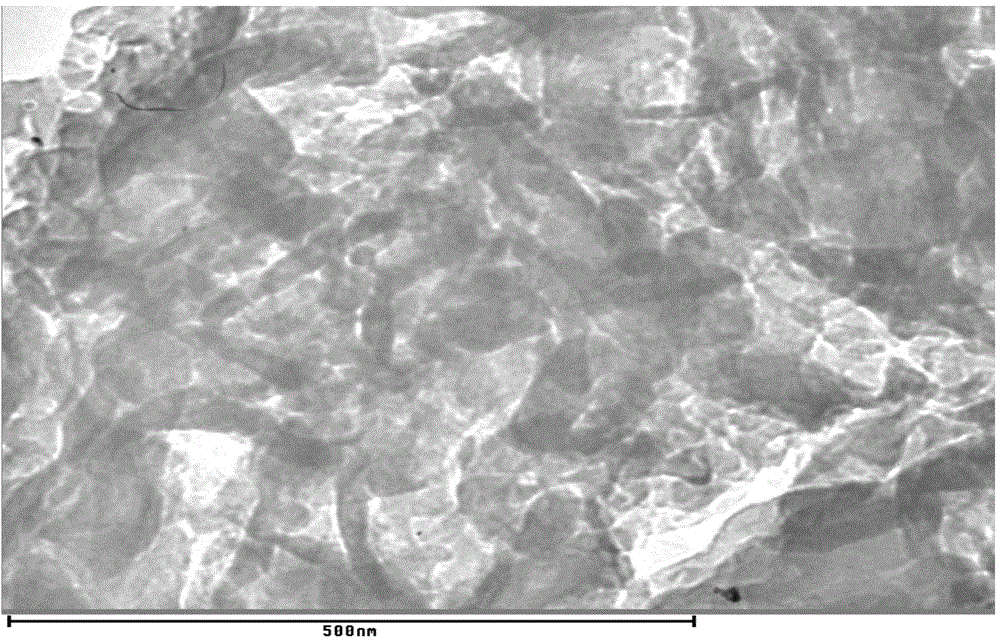

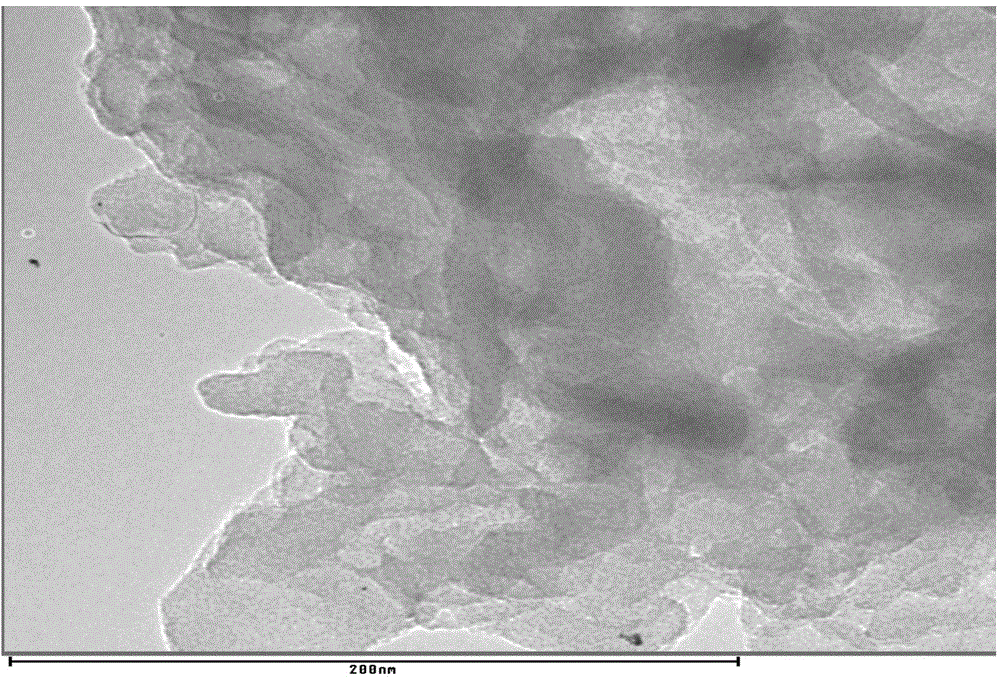

Image

Examples

Embodiment 1

[0024] The preparation method of the sulfur-doped graphite phase carbon nitride visible light catalyst comprises the following steps:

[0025] (1) Dispersing 2g of sulfur powder in 6g of cyanamide aqueous solution with a mass concentration of 50%, fully mixing the two for 60min;

[0026] (2) Place the mixed solution obtained in step (1) in a crucible, cover the crucible lid, put it into a tube furnace, heat up from room temperature to 550°C at a rate of 10°C / min through programmed temperature rise, and heat at a constant temperature for 2h. polycondensation reaction occurs;

[0027] (3) The polycondensation reaction product of step (2) is naturally cooled, washed repeatedly with absolute ethanol and distilled water to remove the by-product ammonium salt, freeze-dried for 24 hours and ground for 1 hour to obtain a sulfur-doped graphite phase carbon nitride visible light catalyst, sulfur element The doping amount accounts for 0.45% by mass of the sulfur-doped graphite phase car...

Embodiment 2

[0031] The present embodiment is different from embodiment 1 in that: the quality of sulfur powder used is 3g. Other steps, parameters and visible light catalysis experimental operation are the same as in Example 1. The doping amount of sulfur in the sulfur-doped graphite phase carbon nitride visible light catalyst prepared in this example accounts for 0.60% by mass of the sulfur doped graphite phase carbon nitride visible light catalyst. The photocatalytic degradation rate of rhodamine B by sulfur-doped graphitic carbon nitride visible light catalyst was 72.3%.

Embodiment 3

[0033] The present embodiment is different from embodiment 1 in that: the quality of sulfur powder used is 0.6g. Other steps, parameters and visible light catalysis experimental operation are the same as in Example 1. The doping amount of sulfur element in the sulfur-doped graphite phase carbon nitride visible light catalyst prepared in this example accounts for 0.25% by mass of the sulfur doped graphite phase carbon nitride visible light catalyst. The photocatalytic degradation rate of rhodamine B by sulfur-doped graphitic carbon nitride visible light catalyst was 51.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com