Clay mineral absorbing material applied to water treatment and preparation method thereof

An adsorption material and clay ore technology, which is applied in the field of adsorption materials and their preparation, can solve the problems that the degree of improvement cannot fully meet the application requirements, the adsorption and purification effect of the adsorption material is unfavorable, and the coagulation effect is not provided, so as to improve the adsorption and coagulation effect. , the effect of increasing the specific surface area and increasing the adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

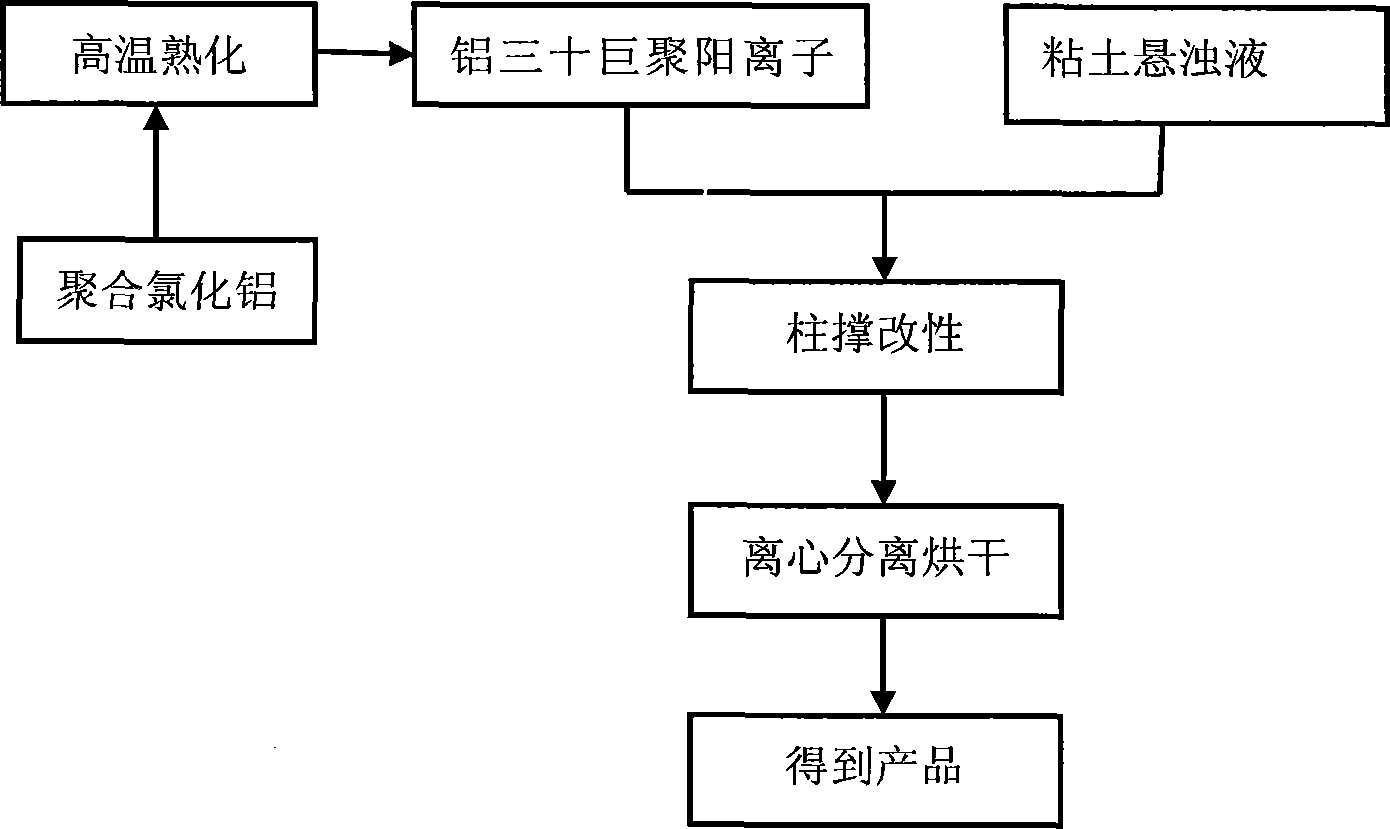

Method used

Image

Examples

Embodiment 1

[0015] Polyaluminum chloride is matured at a constant temperature in a closed reactor, and the temperature is controlled at 90°C. After 36 hours of curing, a bentonite clay ore suspension with a concentration of 10wrt% is added in proportion to make the alumina ratio in the reactor 6mmol. / g, stirred at room temperature for 8 hours to fully mix the materials. Finally, centrifugation is carried out, and the adsorption material is obtained by drying at a temperature of 60°C.

[0016] Compared with before modification, the interlayer spacing of the obtained bentonite increases by 12%, and the specific surface area increases by 55%.

Embodiment 2

[0018] Polyaluminum chloride is matured at a constant temperature in a closed reactor, and the temperature is controlled at 95°C. After 15 hours of aging, the montmorillonite clay ore suspension with a concentration of 10wrt% is added in proportion, so that the alumina ratio in the reactor is 30mmol / g, stirred at 60°C for 2 hours to fully mix the materials. Finally, it was naturally cooled to room temperature, centrifuged, and dried at 60° C. to obtain the adsorption material.

[0019] Compared with before modification, the interlayer spacing of the obtained modified montmorillonite increases by 10%, and the specific surface area increases by 100%.

Embodiment 3

[0021] Polyaluminum chloride is matured at a constant temperature in a closed reactor, and the temperature is controlled at 80°C. After 48 hours of aging, the bentonite clay ore suspension with a concentration of 30wrt% is added in proportion to make the ratio of bauxite in the reactor 20mmol / g, stirred at 40°C for 1 hour to fully mix the materials. Finally, it was naturally cooled to room temperature, centrifuged, and dried at 60° C. to obtain the adsorption material.

[0022] Compared with before modification, the interlayer spacing of bentonite increases by 30%, and the specific surface area increases by 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com