Laying hen feed

A technology of laying hen feed and fish viscera, applied in the field of laying hen feed, can solve the problems of high cost, low calcium absorption rate, unsatisfactory, etc., and achieve the effects of improving production performance, improving egg quality, and promoting absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

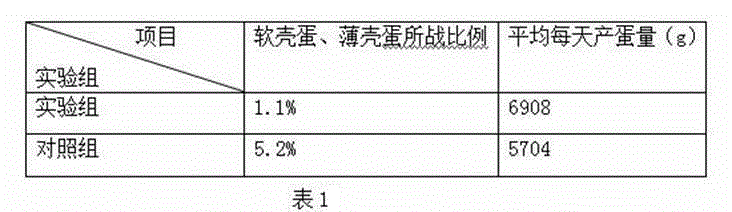

[0022] 58 parts of corn, 12 parts of puffed soybeans, 12 parts of buckwheat, 8 parts of sorghum flour, 5 parts of fish viscera and fish scales, 3 parts of glutinous rice, 4 parts of brewer's yeast powder, 2 parts of spirulina powder, 0.5 parts of sesame, 0.1 part of brown sugar, organic 0.03 parts of selenium, 0.03 parts of organic zinc, and 0.6 parts of garlic powder. Choose 200 similar body weights in the breeding farm, healthy laying hens, random control group and experimental group, every group of 100, the experimental group is continuously fed with the feed configured according to the present embodiment for 1 month, and the control group is fed with traditional feed. The egg production of the two groups is shown in Table 1:

[0023]

[0024] During the comparative feeding process, it was found that compared with the traditional feed, the eggshell quality of the eggs in the feed of the invention was better, and the individual eggs were too large.

Embodiment 2

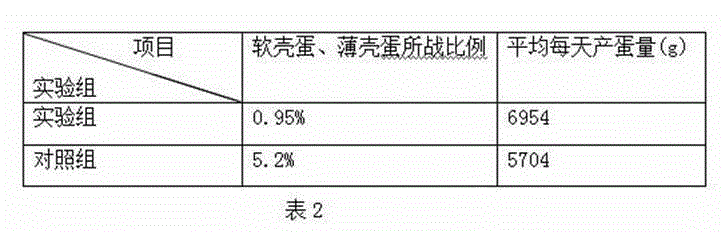

[0026] 68 parts of corn, 15 parts of puffed soybeans, 15 parts of buckwheat, 12 parts of sorghum flour, 8 parts of fish viscera and fish scales, 5 parts of glutinous rice, 5 parts of brewer's yeast powder, 3 parts of spirulina powder, 1 part of sesame, 0.3 parts of brown sugar, organic 0.04 parts of selenium, 0.04 parts of organic zinc, 1.2 parts of garlic powder. Prepare the feed of this embodiment, the feeding method embodiment 1, and the egg production of the two groups are shown in Table 2.

[0027]

Embodiment 3

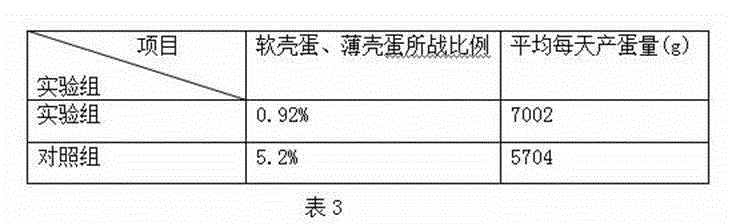

[0029] 62 parts of corn, 13 parts of puffed soybeans, 13 parts of buckwheat, 10 parts of sorghum flour, 7 parts of fish viscera and fish scales, 4 parts of glutinous rice, 5 parts of brewer's yeast powder, 2.5 parts of spirulina powder, 0.8 parts of sesame, 0.2 parts of brown sugar, organic Selenium 0.035 parts, organic zinc 0.035 parts, garlic powder 1.0 parts. Prepare the feed of this embodiment, the feeding method Example 1, and the egg production of the two groups are shown in Table 3 below.

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com