Preparation method of lithium ion battery positive electrode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of slow ion diffusion rate, low mixing uniformity of raw materials, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] (1) Using ethanol as a dispersant, weigh 12.757g (0.304mol) LiOH·H 2 O, 37.197g (0.540mol) LiNO 3 , 8.497g (0.115mol) Li 2 CO 3 , 77.055g (0.32mol) Co 3 o 4 , 0.814g (0.010mol) ZnO and 0.799g (0.010mol) TiO 2 , after oblique mixing treatment for 5 hours, heat preservation at 350°C for 6 hours, then heat up to 1030°C for sintering for 5 hours, and naturally cool to room temperature to obtain block materials;

[0167] (2) crush and sieve the block material prepared in step 1 to obtain a precursor with a particle size of 16.2 μm;

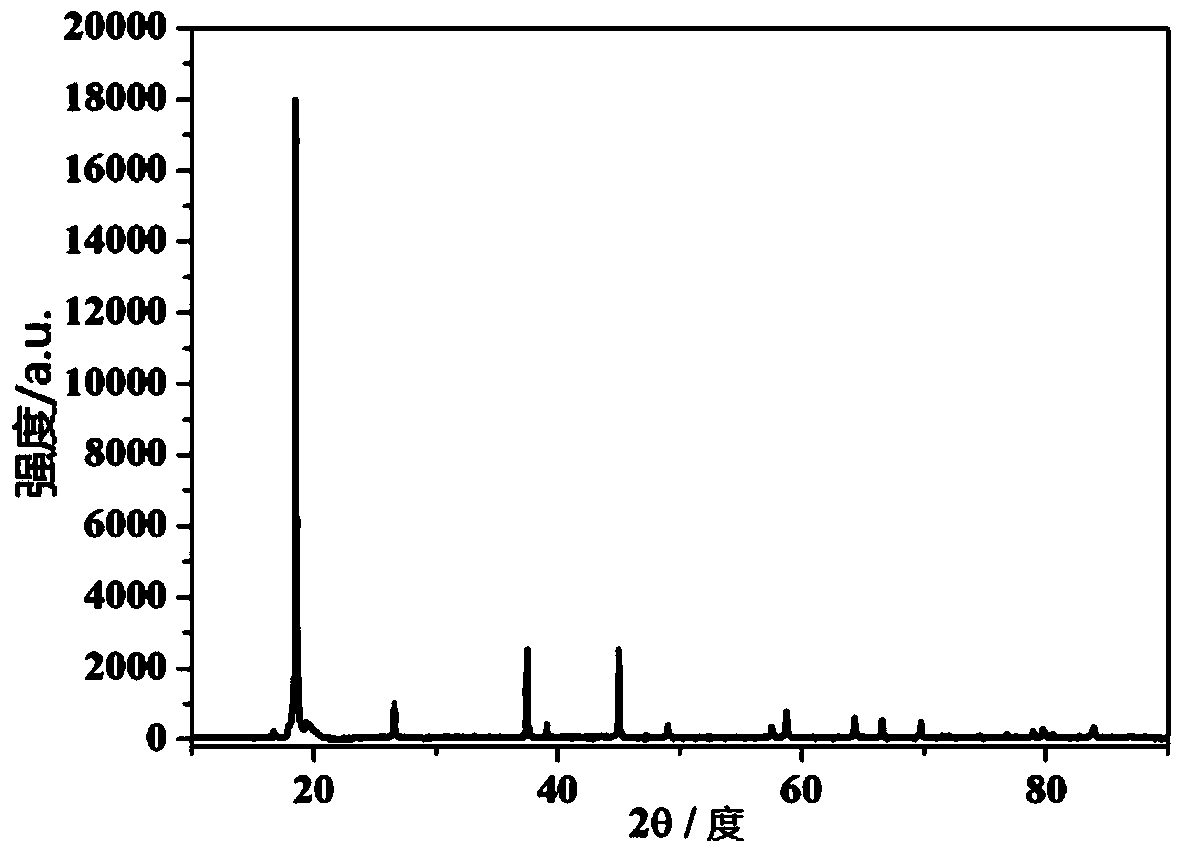

[0168] (3) Mix 2.039g (0.020mol) of alumina with 97.956g of the precursor obtained in step (2) for 2 hours, sinter the uniformly mixed material at 800°C for 5 hours, cool naturally to room temperature, crush and sieve to obtain the average particle size Lithium-ion cathode material with a thickness of 18.4 μm, whose average chemical composition is LiCo 0.96 Ti 0.01 Zn 0.01 al 0.02 o 2 , the XRD pattern of the sample is shown in figure ...

Embodiment 2

[0171] (1) Weigh 15.946g (0.380mol) LiOH·H 2 O, 42.747g (0.62mol) LiNO 3 , 1.158g (0.010mol) Li 3 PO 4 , 78.259g (0.325mol) Co 3 o 4 , 0.504g (0.0125mol) MgO and 1.087g (0.0125mol) MnO 2 , after oblique mixing treatment for 5 hours, heat preservation at 250°C for 6 hours, then heat up to 950°C for sintering for 4 hours, and naturally cool to room temperature to obtain block materials;

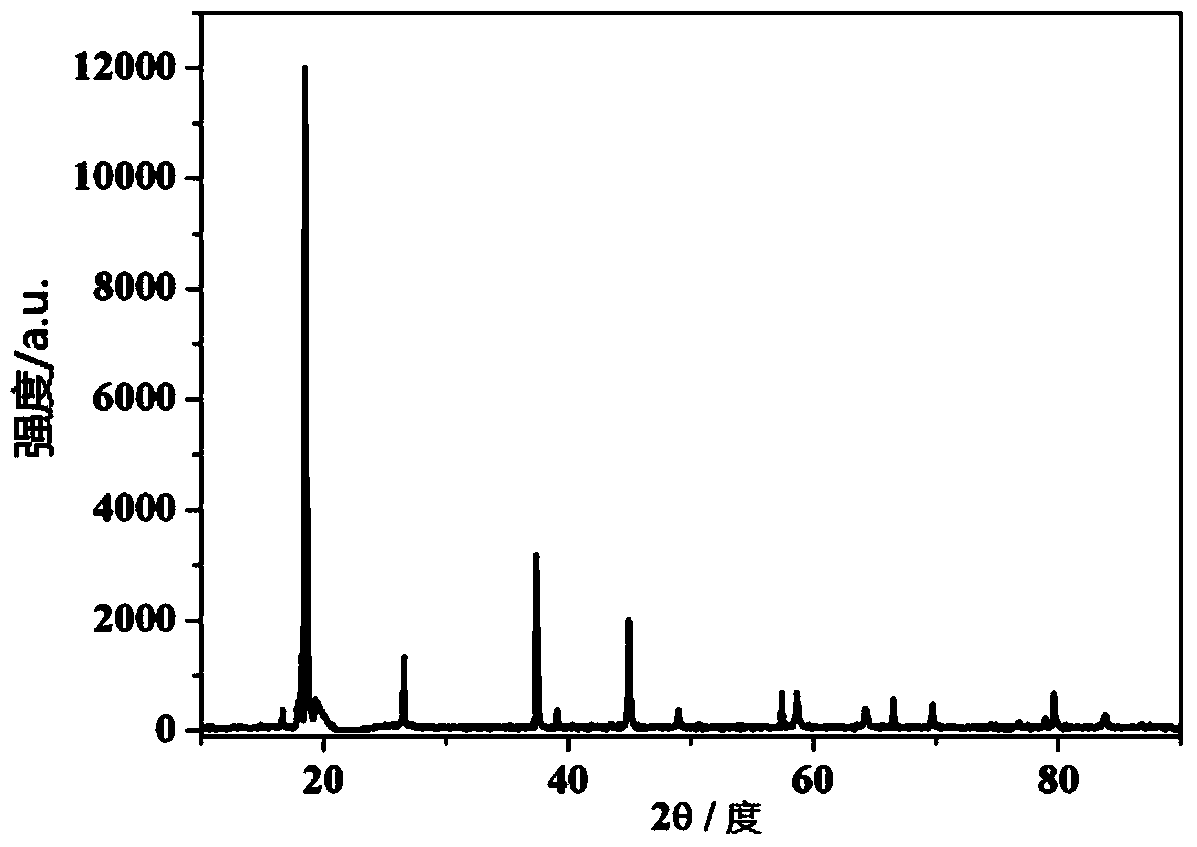

[0172] (2) After crushing and sieving the block material prepared in step 1, a lithium ion positive electrode material with an average particle size of 14.02 μm is obtained, and its average chemical composition is LiCo 0.975 Mg 0.0125 mn 0.0125 o 1.99 P 0.010 , the XRD pattern of the sample is shown in figure 2 shown.

[0173] In the voltage range of 3-4.5V, the specific capacity of the first discharge of this sample is 189.0mAh g at 1C rate -1 , the capacity retention rate of 50 cycles is 95.0%.

Embodiment 3

[0175] (1) Weigh 15.946g (0.380mol) LiOH·H 2 O, 42.747g (0.62mol) LiNO 3 , 0.259g (0.010mol) LiF, 75.449g (0.31mol) Co 3 o 4 , 2.241g (0.03mol) NiO and 1.232g (0.01mol) ZrO 2 , after oblique mixing treatment for 5 hours, heat preservation at 250°C for 6 hours, then heat up to 1010°C for sintering for 4 hours, and naturally cool to room temperature to obtain block materials;

[0176] (2) crush and sieve the block material prepared in step 1 to obtain a precursor with a particle size of 15.7 μm;

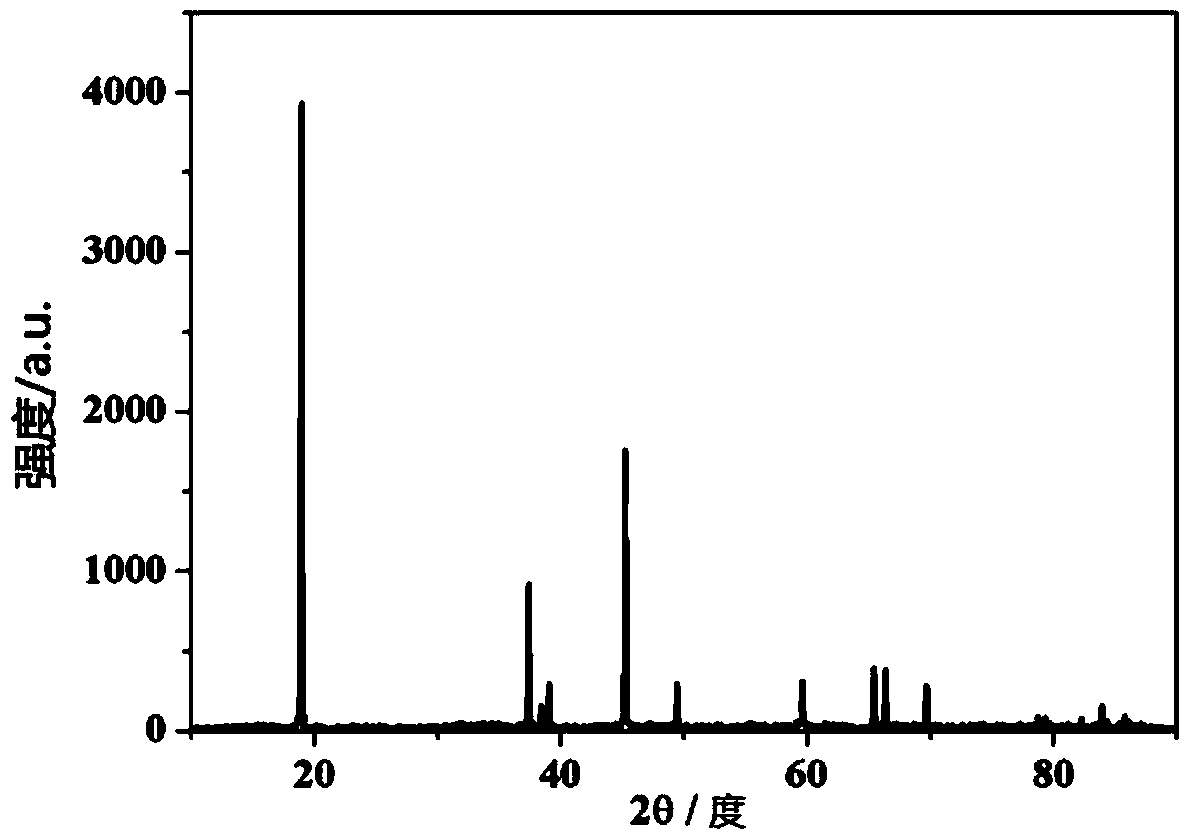

[0177] (3) Take 1.597g (0.020mol) TiO 2 Mixed obliquely with 96.421g of the precursor obtained in step (2) for 2 hours, sintered the uniformly mixed material at 750°C for 5 hours, cooled naturally to room temperature, crushed and sieved to obtain a 17.4μm lithium ion cathode material, and its average chemical composition was LiCo 0.94 Ni 0.03 Zr 0.01 Ti 0.02 o 1.99 f 0.01 , the XRD pattern of the sample is shown in image 3 shown.

[0178] In the voltage range of 3-4.5V, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com