Microfluid control device and method of manufacturing the same

An electro-optical device and driving method technology, applied in optics, nonlinear optics, instruments, etc., can solve problems such as long-term reliability impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

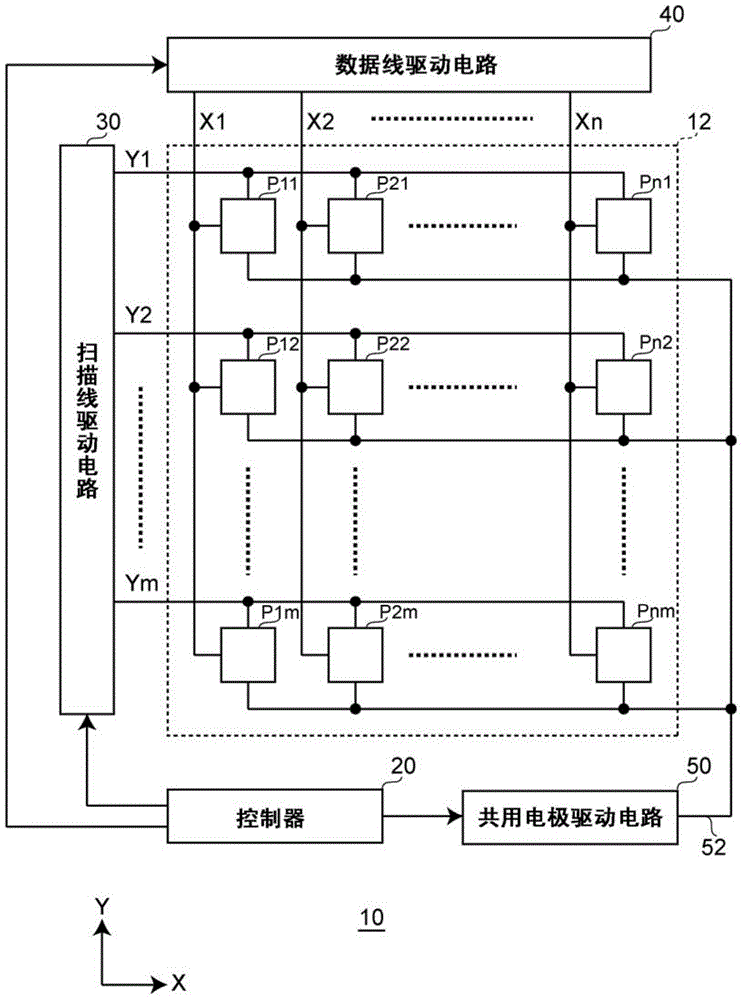

[0066] exist figure 1 A block diagram of a configuration example of an electrophoretic display device as an electro-optical device according to the first embodiment of the present invention is shown in .

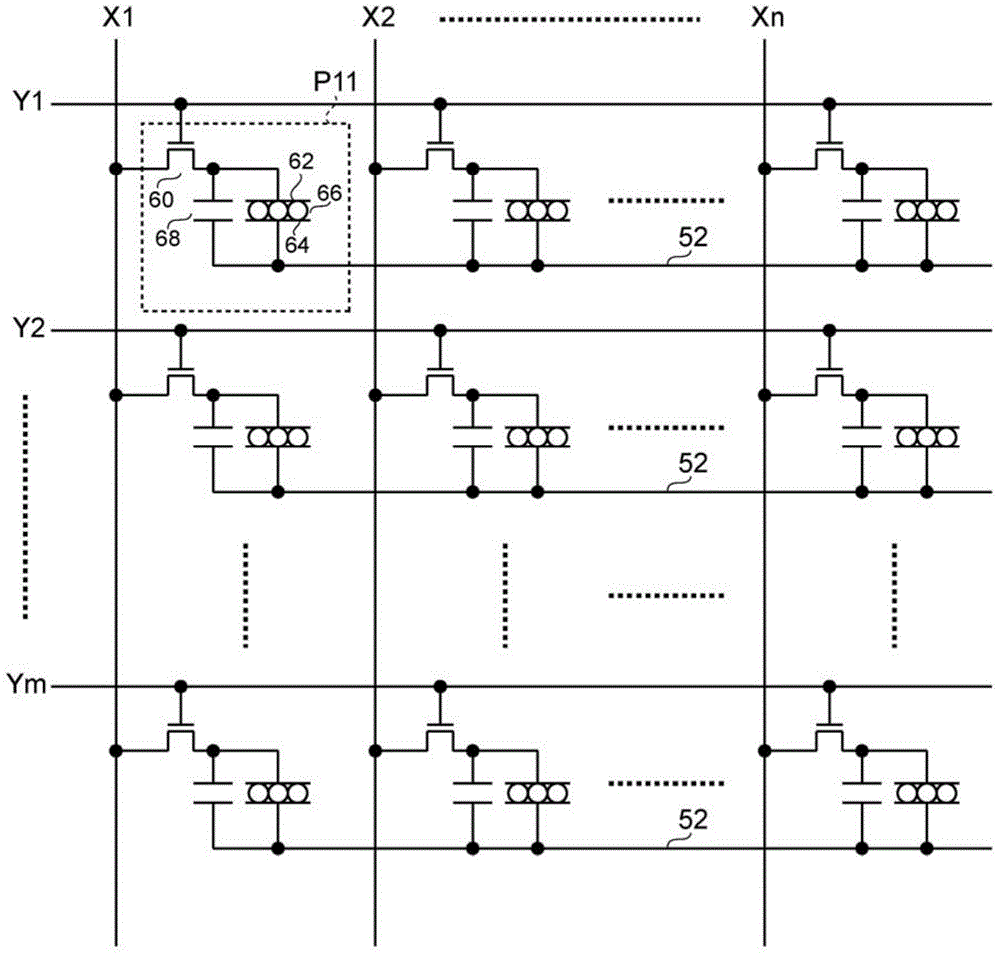

[0067] The electrophoretic display device 10 according to the first embodiment includes a display element having memory in each pixel, and has a property of maintaining a previous display state without updating the display state. This electrophoretic display device 10 includes a pixel area 12 , a controller 20 , a scanning line driving circuit 30 , a data line driving circuit 40 and a common electrode driving circuit 50 . Some or all of the scanning line driving circuit 30 , the data line driving circuit 40 , and the common electrode driving circuit 50 function as a driving device for the electrophoretic display device 10 . Alternatively, you can figure 1 The part of the pixel area 12 is used as an electrophoretic display device, and a controller 20, a scanning line drivin...

no. 2 approach

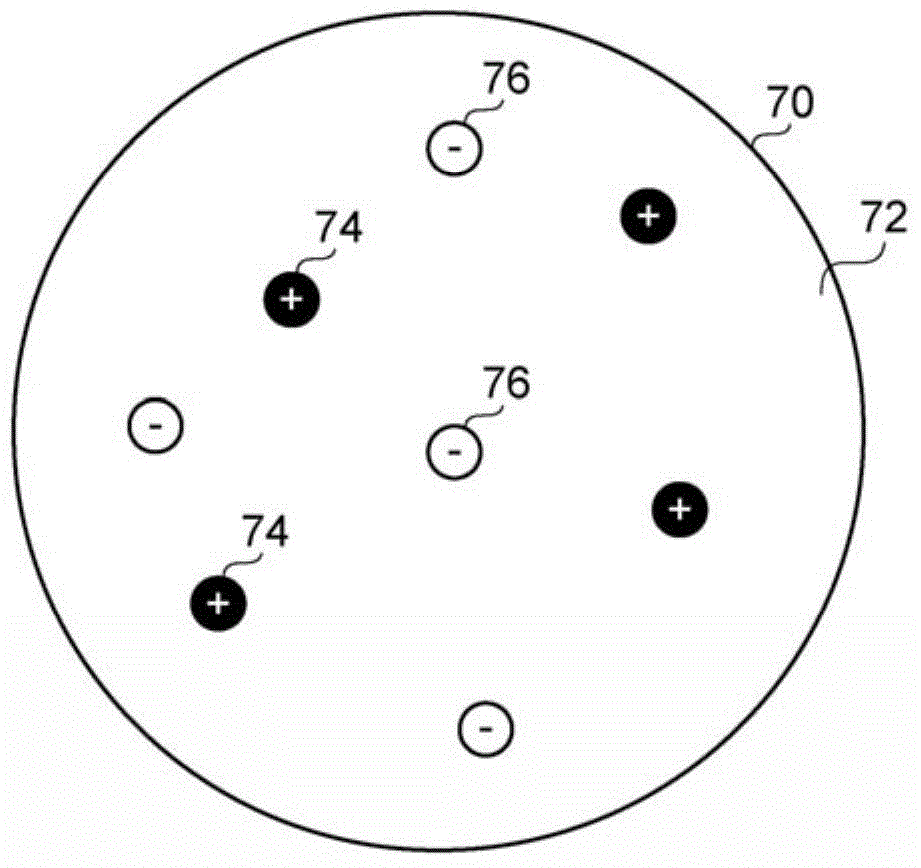

[0108] In the first embodiment, an example in which the microcapsule 70 has the solvent 72 and the electrophoretic particles 74 and 76 and is controlled by two driving voltages has been described, but the embodiments of the present invention are not limited thereto. In the second embodiment, the microcapsule and the solvent have a plurality of electrophoretic particles with mutually different threshold values, and are controlled with four driving voltages. Hereinafter, for the convenience of description, in the second embodiment, differences from the first embodiment will be described.

[0109] exist Figure 9 , the outline of the configuration of the microcapsules constituting the electrophoretic element in the second embodiment is shown. In the second embodiment, figure 2 The electrophoretic element 66 consists of Figure 9 Microcapsules 170 are shown.

[0110] The microcapsule 170 in the second embodiment has an uncolored and viscous solvent 172 , a plurality of electr...

no. 3 approach

[0131] Embodiments of the present invention are not limited to the first embodiment or the second embodiment. In the third embodiment, the microcapsule has a solvent and a plurality of electrophoretic particles having different threshold values, and is controlled by eight driving voltages. Hereinafter, for convenience of description, in the third embodiment, differences from the first embodiment will be described.

[0132] exist Figure 16 , the outline of the configuration of the microcapsules constituting the electrophoretic element in the third embodiment is shown. In the third embodiment, figure 2 The electrophoretic element 66 consists of Figure 16 Microcapsules 270 are shown.

[0133] The microcapsule 270 in the third embodiment includes a viscous solvent 272 colored in black, a plurality of electrophoretic particles 274 colored in red, a plurality of electrophoretic particles 276 colored in green, and a viscous solvent 272 colored in blue. A plurality of electrop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com