Device and method for measuring material quantity of multifunctional self-setting ball mill

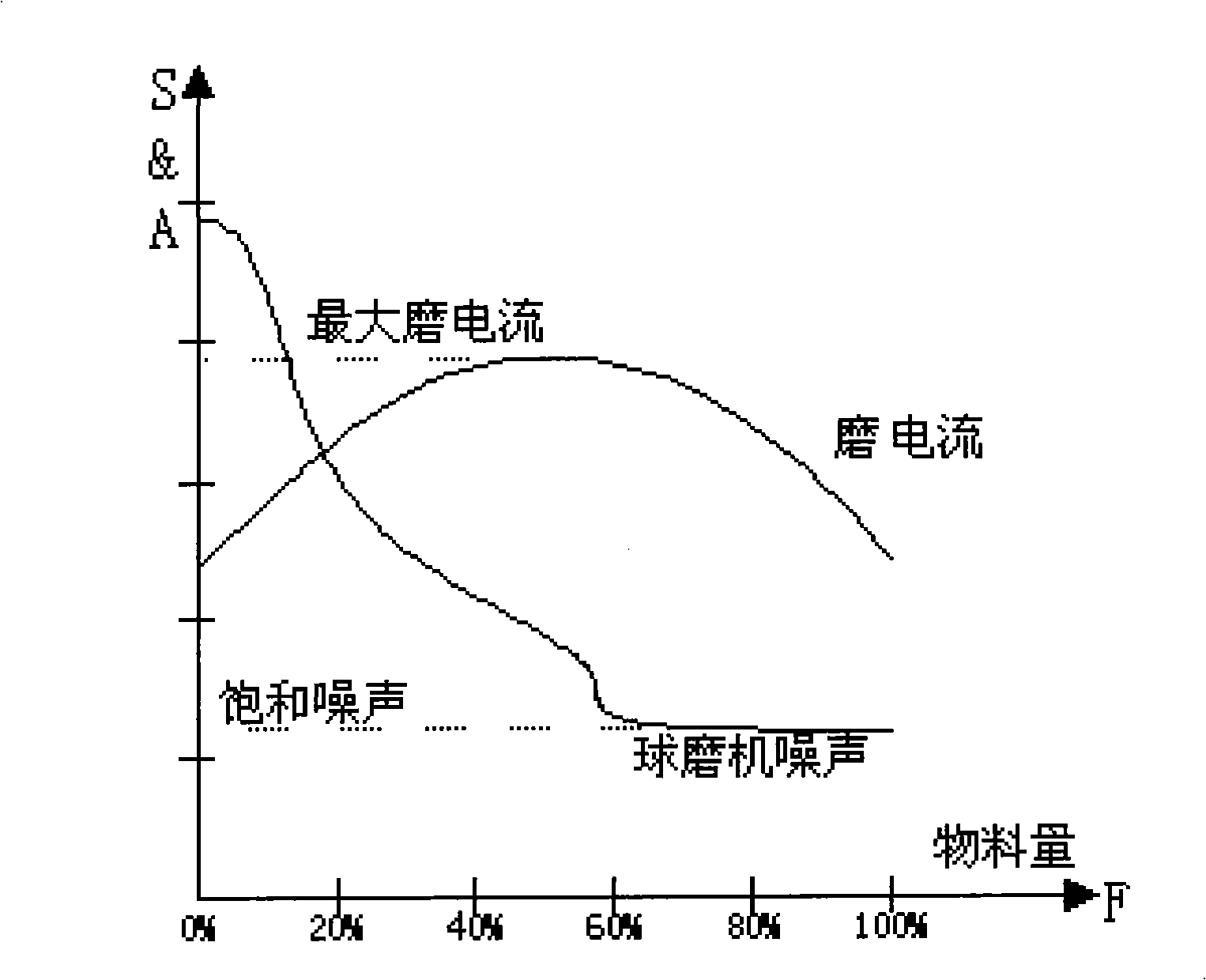

A measuring device and ball mill technology, which is applied in the direction of measuring device, lubrication indicating device, liquid/fluid solid measurement, etc., can solve the problems of inability to measure material quantitatively, large air flow disturbance, and inability to accurately measure the amount of ball mill material for a long time, so as to achieve long-term guarantee Reliability, optimized operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

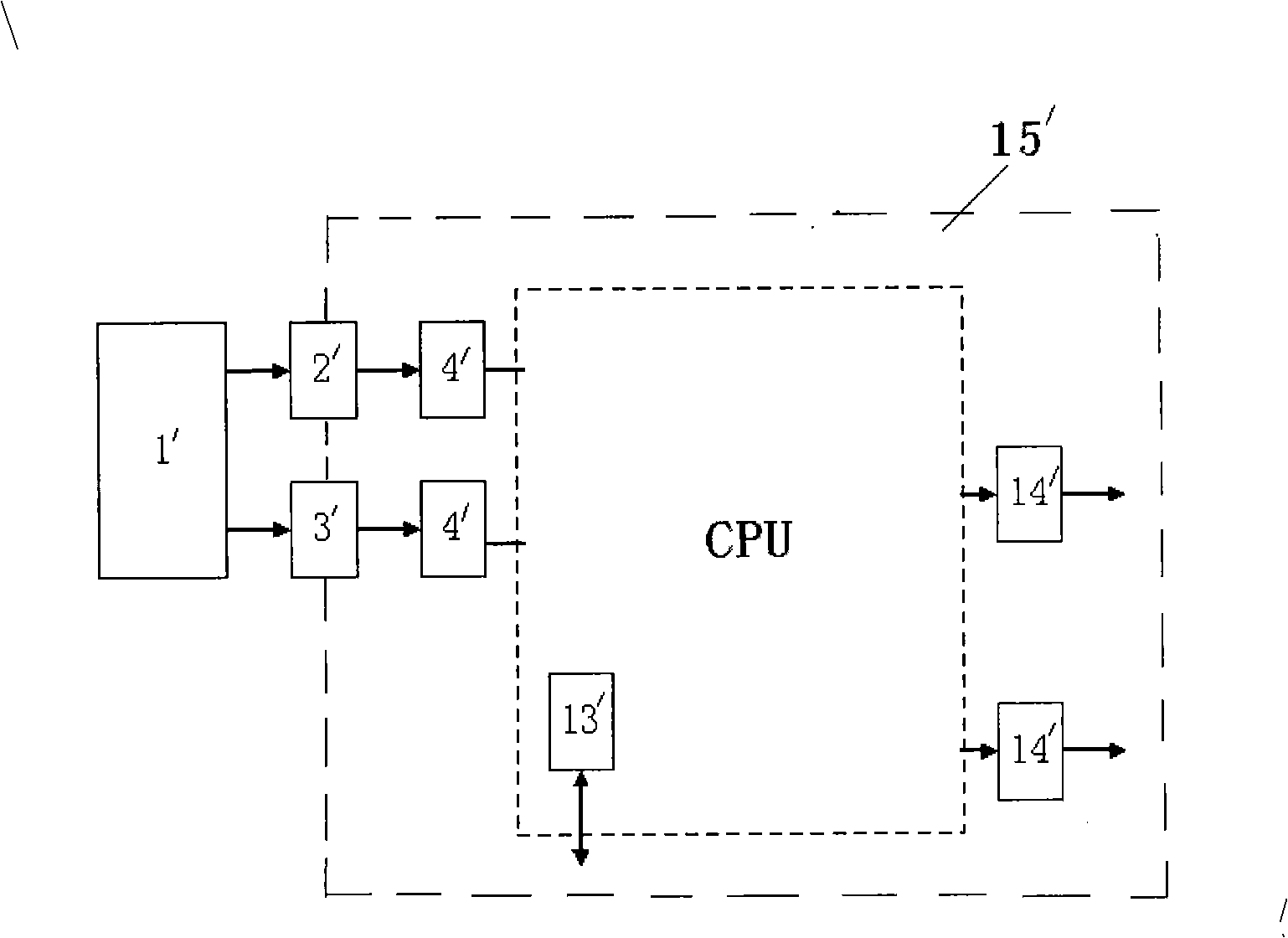

[0038] see figure 2 :

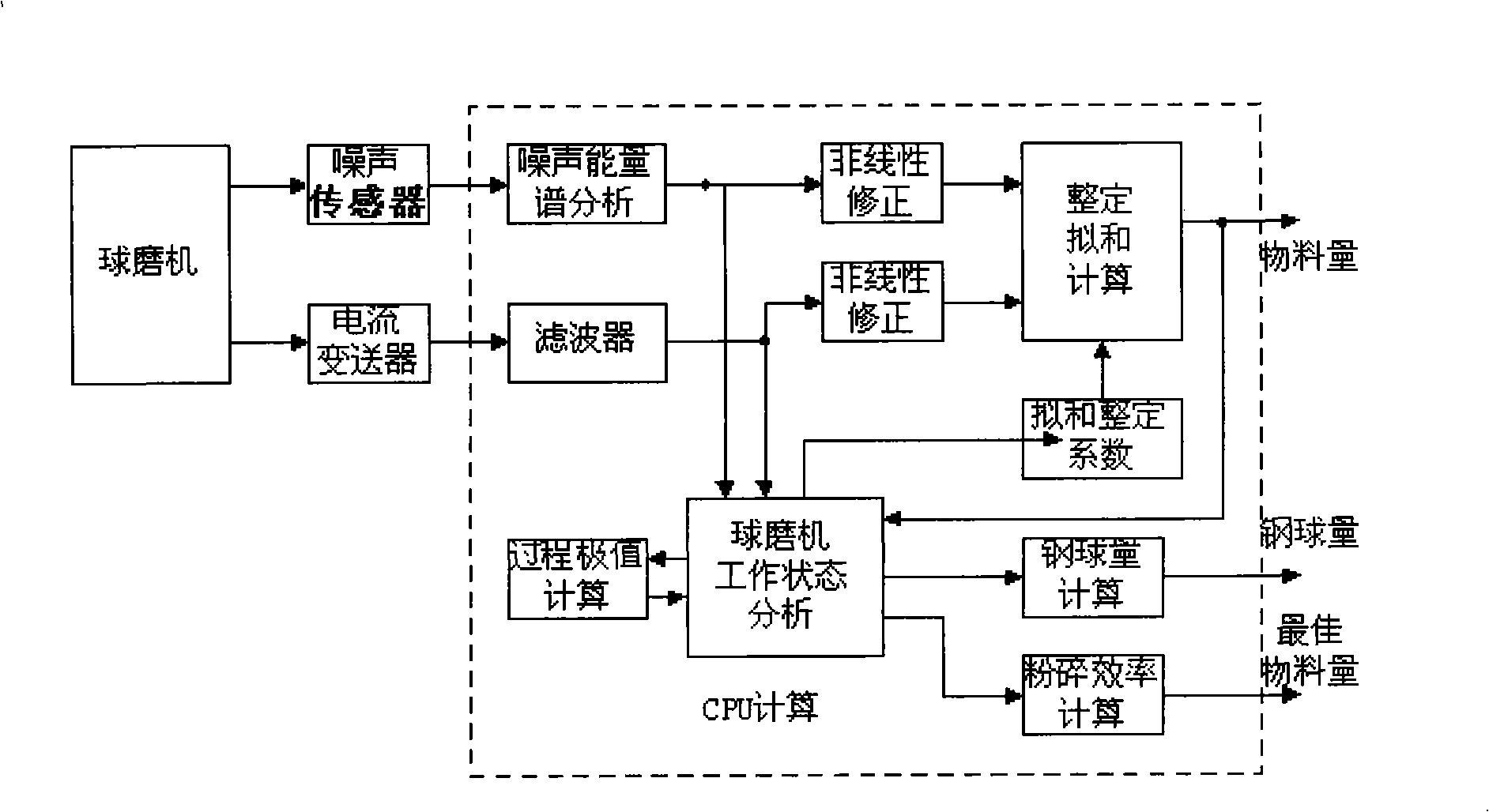

[0039] A multifunctional self-tuning ball mill material quantity measuring device of the present invention is composed of a ball mill noise probe and a multifunctional self-tuning ball mill material quantity transmitter. The noise probe of the ball mill converts the sound energy of the ball mill into an electrical signal by an audio sensor ranging from 10HZ to 20000HZ, and inputs it into the multifunctional self-tuning ball mill material volume transmitter.

[0040] Multifunctional self-tuning ball mill material volume transmitter, the input sound wave energy signal and the 4-20mA mill current signal given by the ball mill motor current transmitter, through the signal processing of the amplifier circuit 4' and the AD conversion circuit 5', converted into digital Quantity, input transmitter built-in microcontr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com