Wear-resistance high-pressure single-screw pump

A single-screw pump and screw technology, applied to pumps, pump components, rotary piston pumps, etc., can solve problems such as degraded pump conditions, increased bushing wear, and poor rotor fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

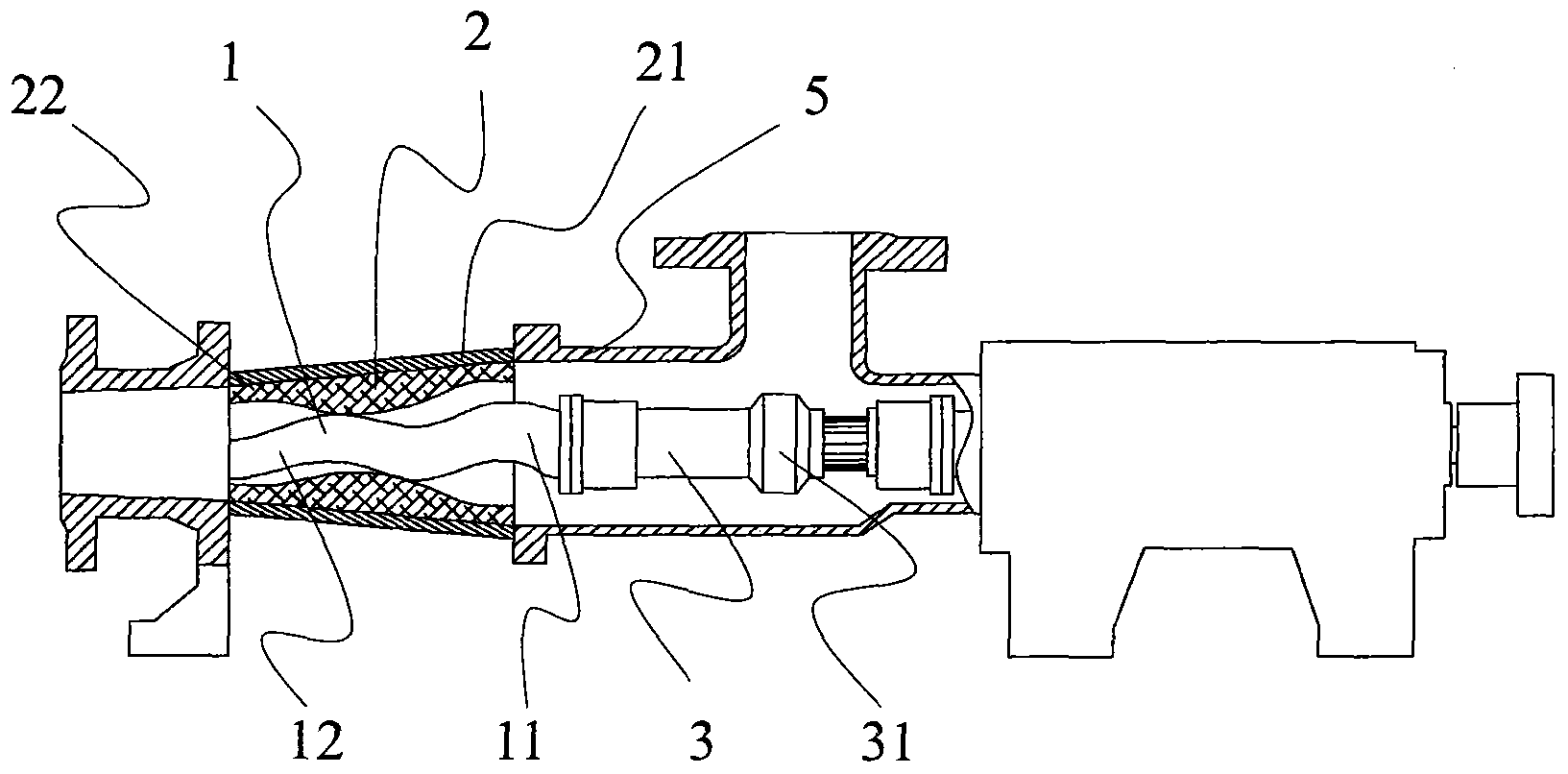

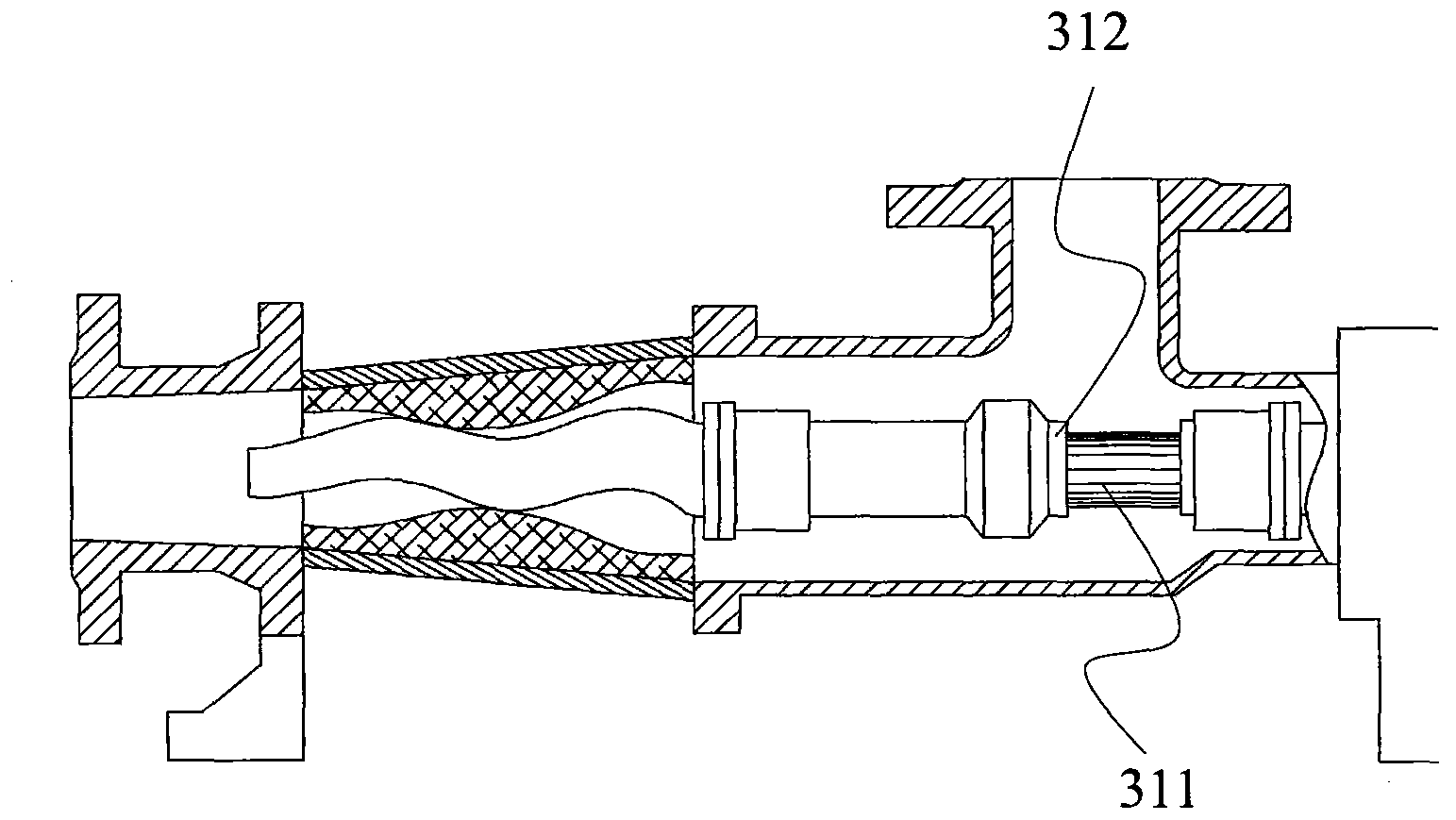

[0025] See attached Figure 1-6 . A single-screw pump comprises a rotor 1 in the shape of a single-head helical screw, a stator 2 with a double-head helical cavity bushing, a connecting shaft 3 with a universal joint, and a feed chamber 5 . One end of the rotor connected to the connecting shaft is the feed end 11 , and the other end is the discharge end 12 . The stator is also divided into corresponding feed end 21 and discharge end 22 . The single-headed helical screw and the double-ended helical cavity are arranged in the shape of a trumpet with a thick feed end and a thin discharge end, and the length of the feed end of the screw is somewhat redundant. The screw bushing position adjusting device is a length adjusting device 31 arranged on the connecting shaft. The length adjusting device 31 includes a spline 311 , a sleeve 312 and a length locking device 313 .

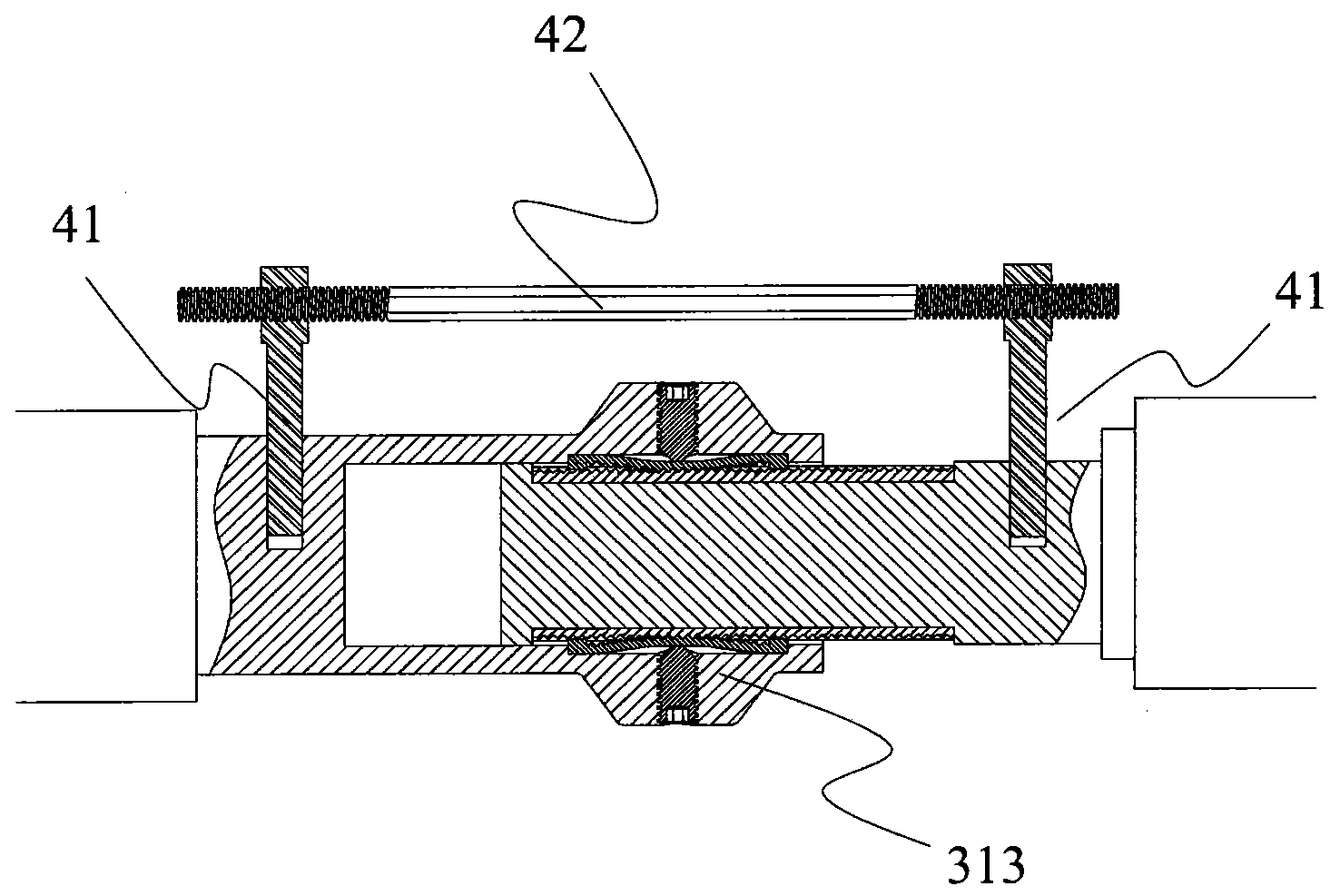

[0026] Locking device 313 see attached Figure 3-4 , consisting of two sets of top screws 3131, spring teeth...

Embodiment 2

[0029] See attached Figure 7-8 , a single-screw pump, including a rotor 1 in the shape of a single-head helical screw, a stator 2 with a double-head helical cavity bushing, a connecting shaft 3 with a universal joint, and a feed chamber 5 . One end of the rotor connected to the connecting shaft is the feed end 11 , and the other end is the discharge end 12 . The stator is also divided into corresponding feed end 21 and discharge end 22 . The single-headed helical screw and the double-ended helical cavity are set in the shape of a trumpet with a thick feed end and a thin discharge end, and the length of the discharge end of the screw is somewhat redundant. The position adjusting device of the screw bush is a telescopic joint 51 arranged on the feed chamber 5 .

[0030] When the new pump has just been assembled, the expansion joint is in the longest state, and the discharge end of the screw is flush with the discharge end of the bushing. After a period of use, the bushing and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com