Horizontal water tilling machine

A water cultivator and horizontal technology, which is applied in the field of aquaculture equipment, can solve the problems of slow impeller speed, single function of the water cultivator, inability to solve fish and shrimp floating heads, etc., and achieve the effect of convenient assembly and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

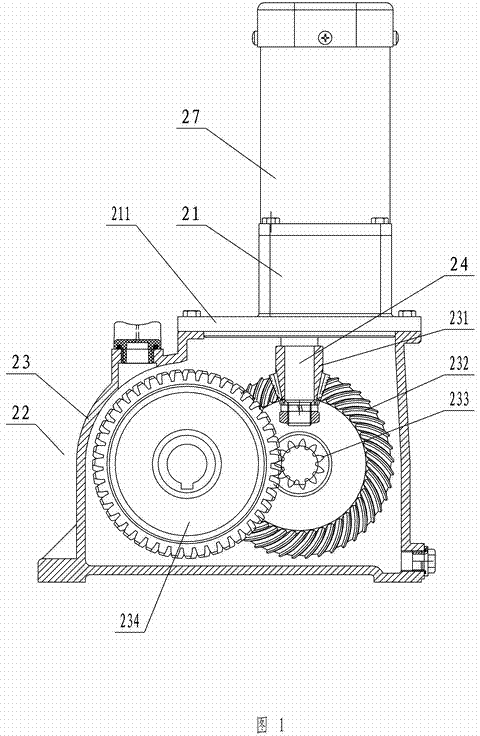

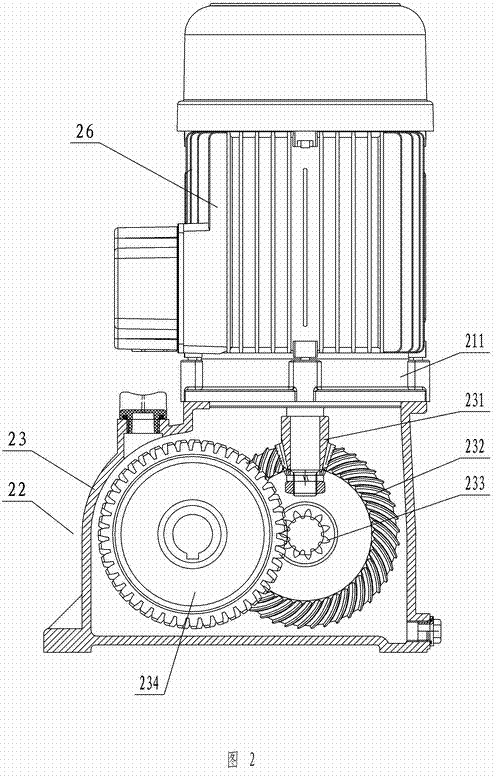

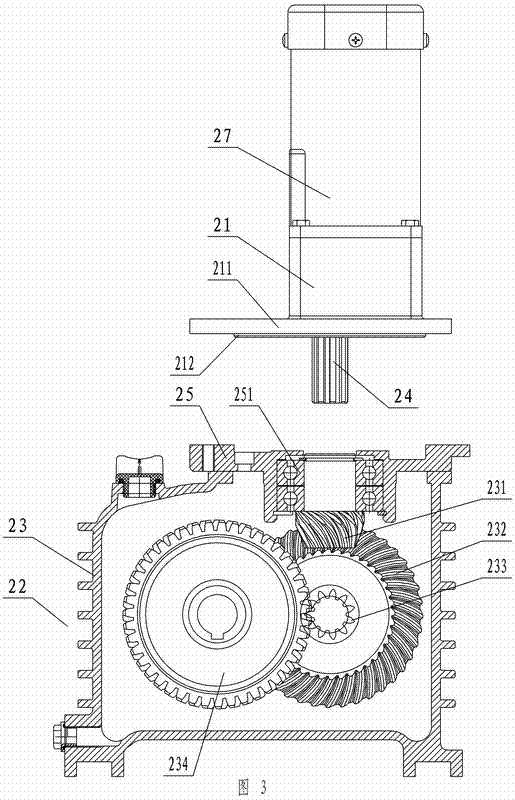

[0056] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-25 :

[0057] A horizontal cultivating machine mainly includes: a motor, a reduction box, an impeller, and a floating body. The reduction box is divided into a primary reduction box 21 and a secondary reduction box 22. The primary reduction box 21 can be combined with the motor 27. , set different reduction ratios, the output shaft 24 of the primary reduction box 21 drives the small bevel gear 231, the small bevel gear drives the large bevel gear 232, the large bevel gear and the small cylindrical gear 233 are coaxial, the small cylindrical gear drives the large cylindrical gear 234, and the output The shaft 24 stretches out from one side or two sides of the casing 23 after being sealed to drive the impeller 1 to rotate, and the complete machine floats on the water surface by the buoyant body.

[0058] The primary reduction box 21 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com