Method for controlling fuel injection system

A fuel injection system and internal combustion engine technology, applied in fuel injection pumps, fuel injection devices, fuel injection control, etc., can solve problems such as high cost, and achieve the effect of shortening start-up time and restart time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

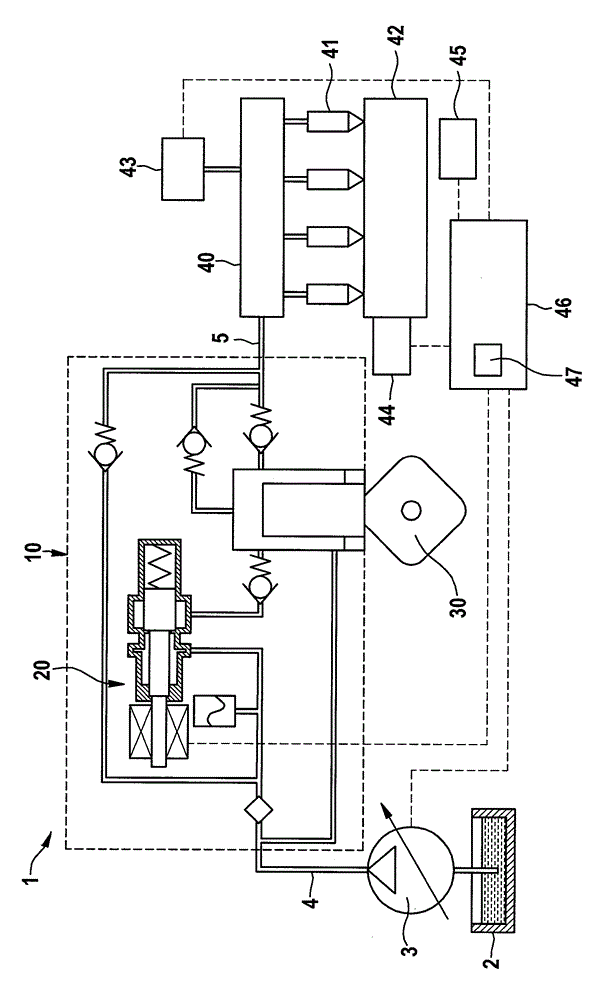

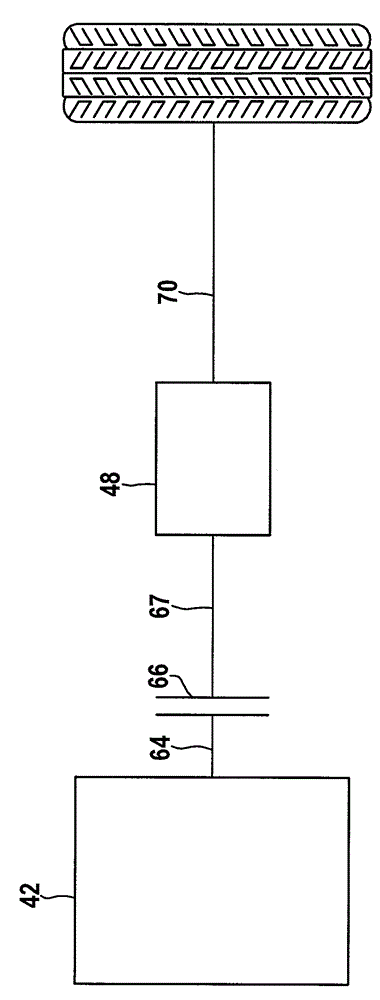

[0027] figure 1 A schematic diagram of a fuel injection system 1 of an internal combustion engine 42 with start-stop function is shown. The fuel injection system comprises a fuel container 2 from which a pre-feed pump 3 pumps fuel via a line 4 with a corresponding pre-feed pressure to a high-pressure fuel pump 10 driven via a cam 30 . A flow control valve 20 is arranged on the high-pressure pump 10 on the low-pressure side. The delivery volume of the high-pressure pump 10 is set by means of the flow control valve 20 . The cam 30 is driven by the internal combustion engine 42 , for example by an associated motor shaft, and can also be a component thereof. This motor shaft is figure 2 is explained in detail and marked with 64.

[0028] The high-pressure pump 10 preferably has a delivery chamber with a non-return valve arranged on the inlet side. The high-pressure pump compresses the fuel to a particularly high pressure and conveys it via a line 5 into a high-pressure accum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com