Wall linking method of scaffold and wall-linking member used by scaffold

A technology for connecting wall parts and scaffolding, which is applied in the field of building scaffolding, which can solve the problems of difficult pre-embedded steel pipes to be extracted and reused, hard-to-cut parts and large steel consumption, etc., so as to achieve small installation difficulty, smooth walls, The effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

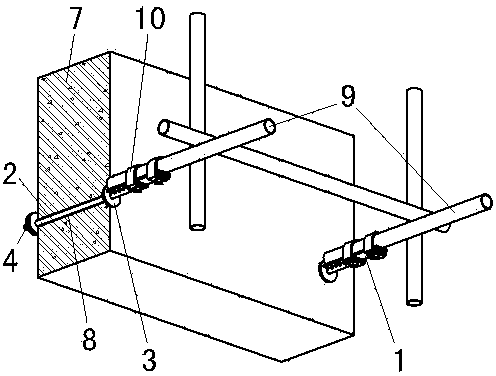

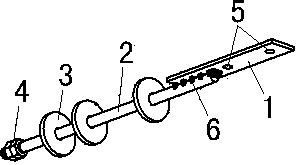

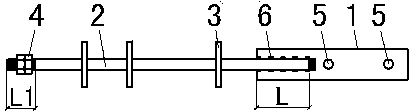

[0022] During the specific implementation, the wall parts are processed according to the design requirements of the scheme. The connecting plate in the wall parts adopts the Q235B flat steel with a specification of 40×5. Two connecting holes are opened on one end of the connecting plate at a distance of 25mm and 105mm, and the other end is welded to the middle of the flat iron with a 400mm long Φ14 wall-through bolt rod, and 5 points are welded on both sides to make a connecting wall piece. During the formwork support process of the shear wall, Φ20 PVC sleeves are pre-embedded at the position where the wall parts need to be installed, and the formwork is removed and the outer frame is pulled and connected. The wall-connecting parts use welded wall-through screws to pass through the pre-embedded PVC pipe sleeve of the shear wall, and are fixed to the shear wall with nuts and washers. The steel pipes connected to the outer frame are connected to the connecting plate with reserv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com