Frit composition, frit paste composition and sealing method and electric device

A technology for electrical devices and compositions, which is applied in the field of glass frit compositions, glass frit paste compositions, and electrical devices, and can solve the problems of unsealable air bubbles, easy cracking, and reduced packaging yield, so as to improve packaging Stability, avoid cracking, reduce the effect of porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 of the present invention provides a glass frit composition, including a glass frit substrate and a filler, and the filler includes a quasicrystalline material.

[0047] The quasicrystalline materials are Al-transition metals, including Al x Cu y Fe z , Al x Cu y co z ,, Al x Cu y mn z, Al x mn y Si z , Al x mn y Fe z , Al x mn y Zr z , Al x' mn y' sn z' mn w' , where the relationship between x, y, z satisfies:

[0048] x+y+z=100, and

[0049] 60

[0050] 5

[0051] 5

[0052] Among them, the relationship between x', y', z' and w':

[0053] x'+y'+z'+w'=100, and

[0054] 60

[0055] 5

[0056] 5

[0057] 5

[0058] Further preferably, the quasicrystalline material is Al 65 Cu 20 Fe 15 , Al 65 Cu 15 co 20 , Al 65 Cu 20 mn 15 at least one of the materials.

[0059] The crystal structure of the quasicrystal particles of the quasicrystal material is: 5th, 8th, 10th, 12th, etc. r...

Embodiment 2

[0063] Embodiment 2 of the present invention also provides a glass frit paste composition, including any one of the glass frit compositions described above. The frit paste composition also includes an organic binder and a solvent.

[0064] In the present invention, the above glass frit paste composition can be used to hermetically seal electrical components such as organic light-emitting display panels, light-emitting diode (LED) lighting fixtures, or dye-sensitized solar cells (DSSC). In the glass frit paste composition, the glass frit substrate is a supporting substance, and the filler is a substance used to improve the physical and chemical properties of the glass frit composition, just as the quasicrystalline material in the present invention can improve the glass frit composition The thermal expansion coefficient of the material, and because the glass frit base material is powdery, and the filler is granular, the glass frit base material and the filler are mixed, and the ...

Embodiment 3

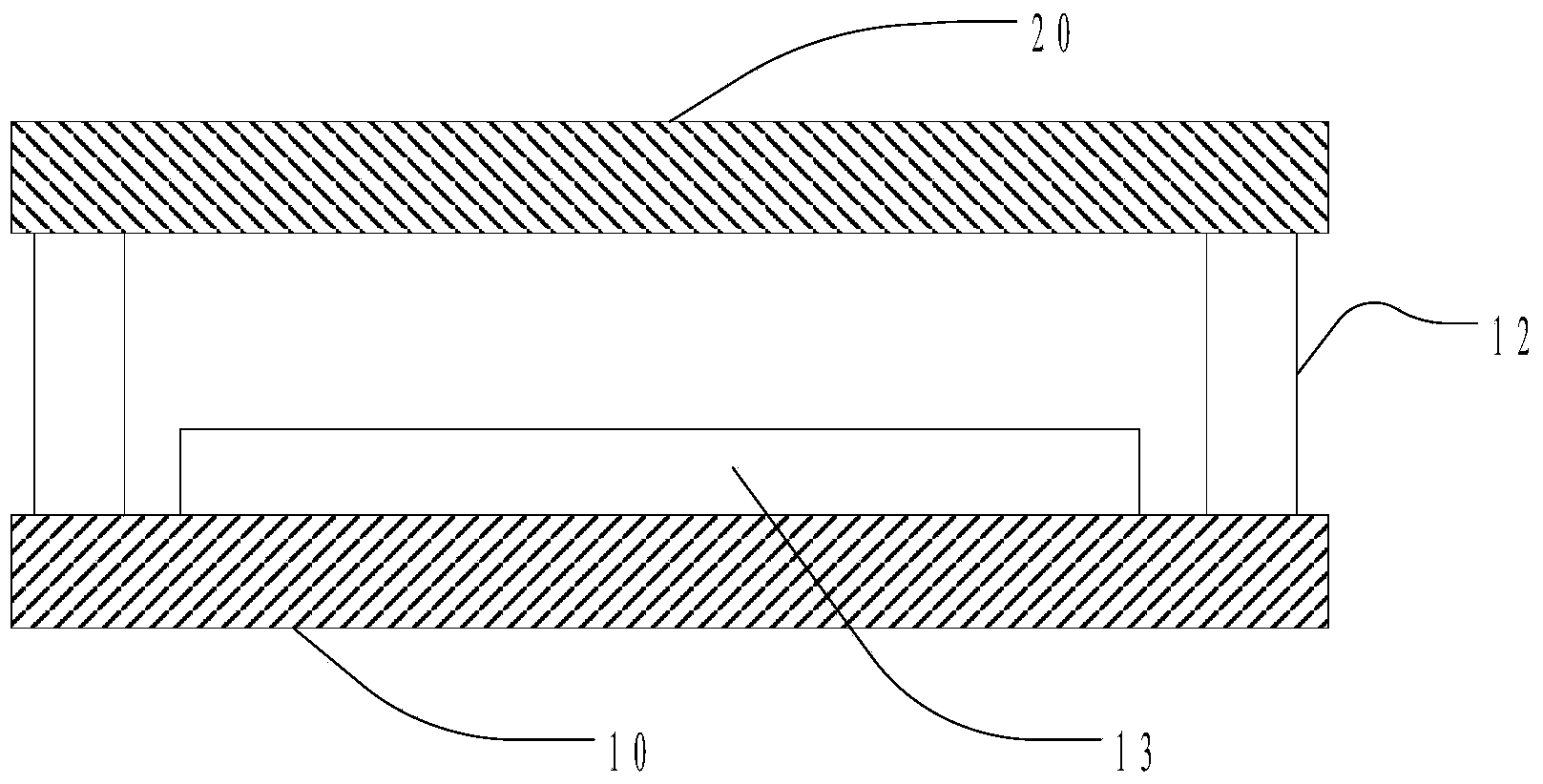

[0068] Based on the glass frit paste composition provided in the above embodiment, Embodiment 3 of the present invention also provides a sealing method using a glass frit paste composition, such as Figure 4 shown, including the following steps:

[0069] Step 1, providing a first substrate, wherein the first substrate is provided with a glass frit paste composition.

[0070] Wherein, the glass frit paste composition described on the first substrate is the glass frit paste composition provided in the above examples. Specific as Figure 5 The top view of the first substrate provided by the illustrated embodiment of the present invention includes a first substrate 10 on which an encapsulation area 11 and electrical components 13 are arranged, and the frit paste composition is deposited on the first substrate 10 of the encapsulation area 11 . Specifically, the glass frit paste composition may be deposited on the packaging area 11 of the first substrate 10 by dispensing or scree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com